Heat transfer coefficient adjustable heat-exchange device

A heat exchange device and heat transfer coefficient technology, applied in the field of heat exchanger devices, can solve problems such as unadjustable heat exchange power, and achieve the effects of eliminating hidden dangers of physical and chemical reactions, enhancing safety, and high heat exchange temperature difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

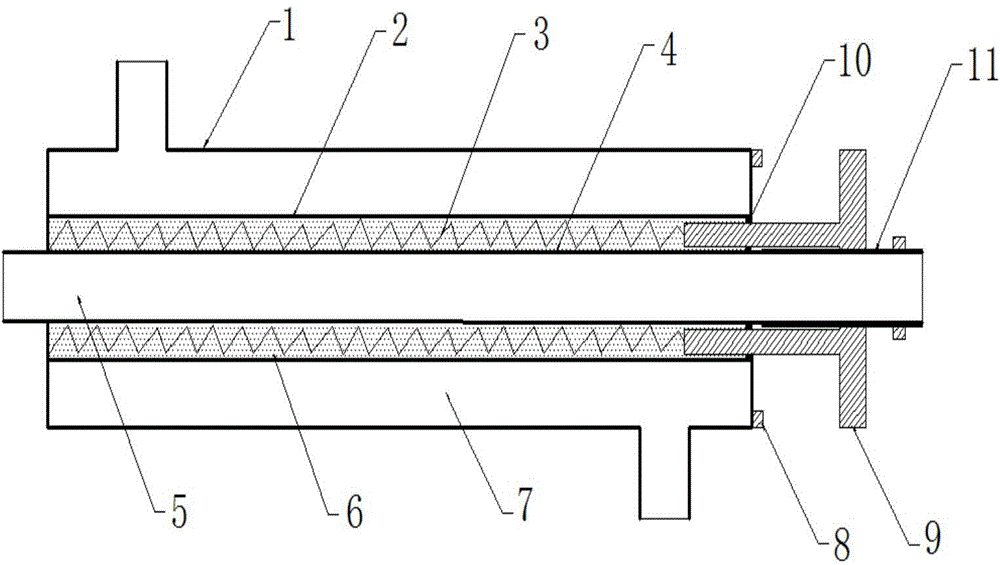

[0015] The present invention is a heat exchange device with adjustable heat transfer coefficient, which can be applied to nuclear industry and metal manufacturing industry. The present invention will be further described below in conjunction with the accompanying drawings.

[0016] A heat transfer device with adjustable heat transfer coefficient, comprising an outer tube 1, an intermediate tube 2, an elastic device 3, an inner tube 4, heat-conducting powder 6, a limiting device 8, a driving mechanism 9, a sealing device 10, and a running track 11; There is an elastic device 3 in the space surrounded by the tube 2 and the inner tube 4, one end of which is fixedly connected to the left fixed end of the heat exchange device, and the other end is connected to the driving mechanism 9; the driving mechanism 9 is installed on the right movable end of the heat exchange device, and can run along the The track 11 moves in the axial direction of the inner tube 4, and the displacement is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com