Wood damage monitoring method based on acoustic emission technique

An acoustic emission technology and damage monitoring technology, which is applied in the field of wood, can solve the problems of distortion, air cracking and other problems, and achieve the effect of avoiding attenuation, avoiding major losses, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

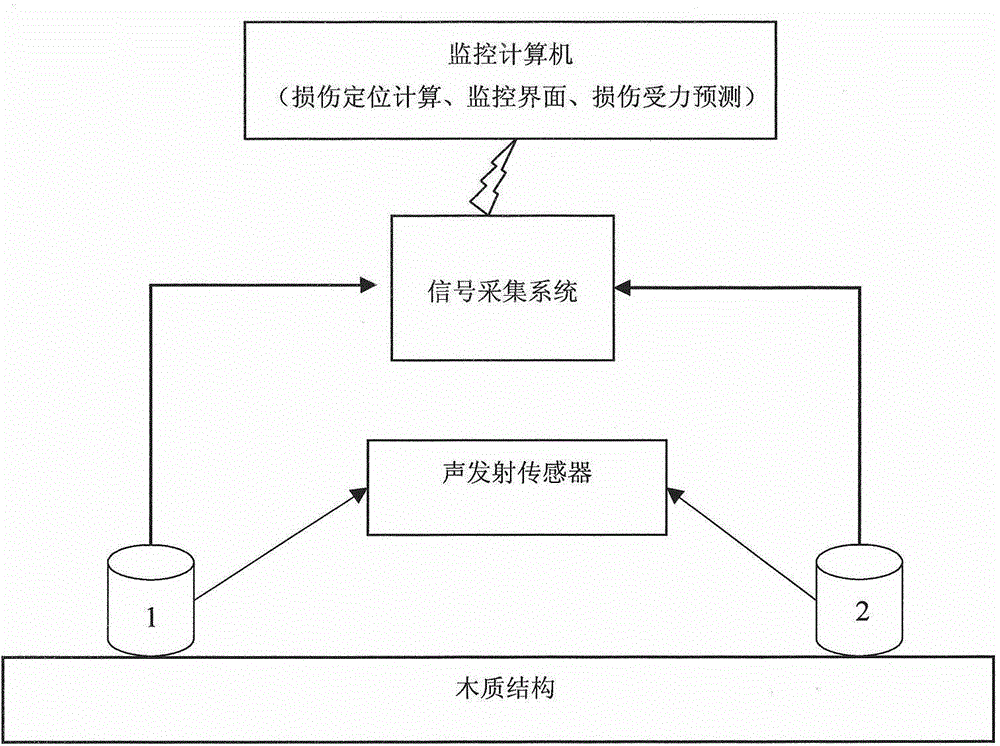

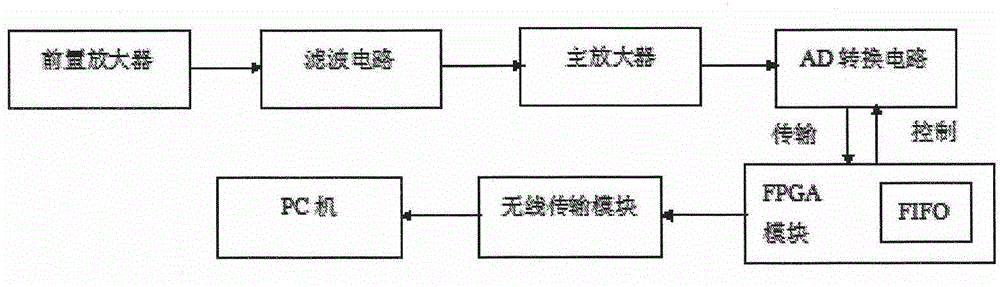

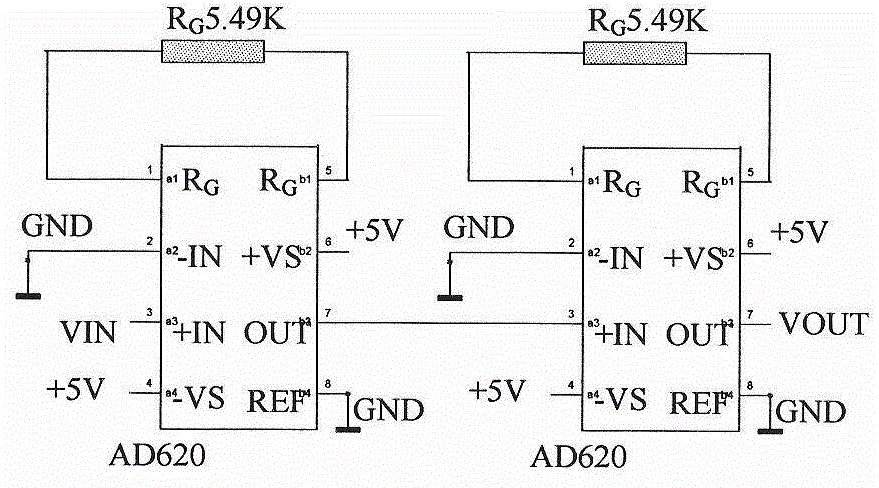

[0036] The wood damage monitoring method based on the acoustic emission technology proposed by the present invention is described in detail as follows in conjunction with the accompanying drawings and embodiments. The invention takes wood as the measured object, and monitors the acoustic emission signal emitted by the damaged wood. attached figure 1 Schematic diagram of acoustic emission signal acquisition for wood stress damage. The frequency bandwidth of the acoustic emission signal is between 100KHz-300KHz, so the acoustic emission sensor in this design uses an ultrasonic sensor with a center frequency of 60Hz-400KHz and a center frequency of 150KHz. First place the acoustic emission sensor on an important part of the wood where the stress is concentrated. When the wood is deformed under the condition of internal or external force, a stress wave will be generated. The acoustic emission sensor converts the stress wave into an electrical signal. Since the electrical signal i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com