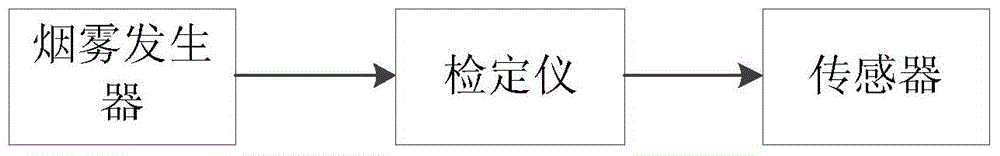

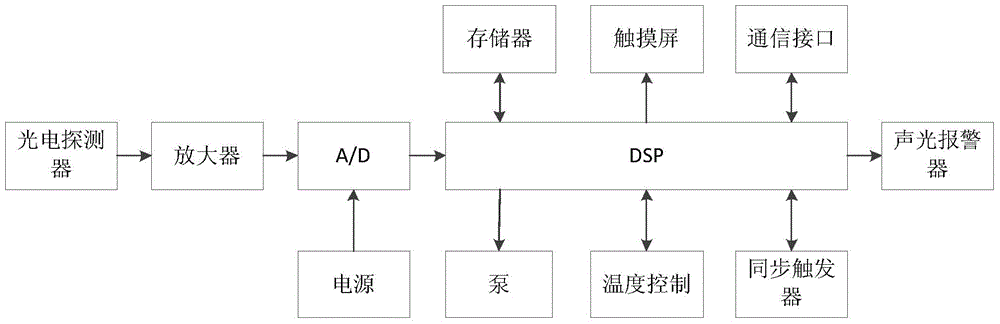

Smoke detector certification device and calibration method based on laser light scattering measurement principle

A technology of smoke detectors and measurement principles, which is applied in the direction of transmittance measurement, instruments, alarms, etc., can solve the problems of large mass concentration and response time measurement errors, inability to complete smoke concentration verification, and difficult control of smoke mass concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

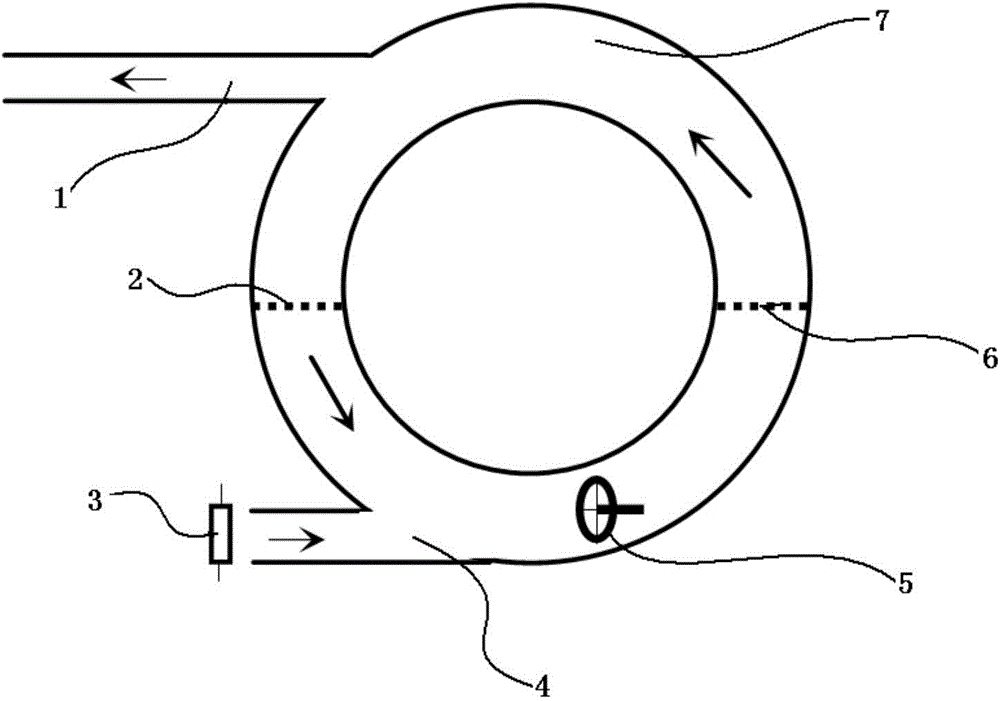

[0023] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings; it should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

[0024] The suspended aerosol particles produced by the fire form smoke. The higher the particle content, the higher the smoke concentration and the better the light blocking effect, and vice versa. Therefore, the shading rate is used to measure the level of smoke concentration and determine the development stage or severity of the fire. The mine smoke sensor accurately measures the smoke concentration with the shading rate of smoke with a thickness of 1m, and its mathematical definition is:

[0025] S = ( 1 - I o I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com