Polarization-reconfigurable high-power microwave feed source

A high-power microwave and feed technology, applied to waveguide speakers, electrical components, circuits, etc., can solve the problems that cannot meet the compactness requirements of the antenna feed system, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

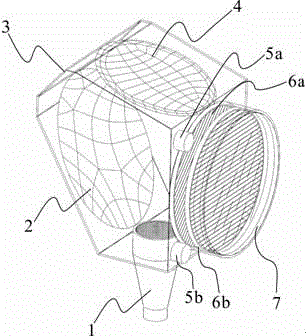

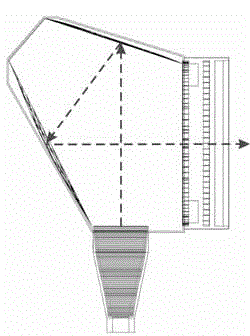

[0023] Such as figure 1 As shown, the present invention is composed of a corrugated horn, a first phase correcting mirror, a box body, a second phase correcting mirror, two stepping motors, two circular polarization grids and a dielectric window. The box is evacuated to increase power capacity.

[0024] The corrugated horn is a commonly used horn in the microwave field. It is made of metal and its function is to output the TE of the high-power microwave device. 11 Mode high power microwave conversion to HE 11 Mode and radiate out with quasi-Gaussian beam.

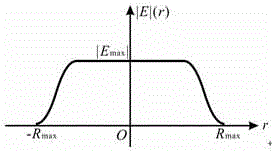

[0025] The first phase correction mirror is made of metal and is a concave mirror surface. The surface shape is specially designed. Its function is to irradiate the corrugated horn onto the first phase correction mirror with a Gaussian distribution beam for phase correction to achieve the desired feed The source output beam cross-sectional amplitude distribution irradiates the second phase correction mirror.

[0026] The second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com