Multi-section sliding rail allowing splicing

A slide rail, slide rail fixing technology, applied in furniture parts, home appliances, drawers, etc., can solve the problems that the effective length cannot meet the length requirement, the strength of the slide rail cannot be maintained, and it is difficult to popularize and apply, so as to improve the effective use length. , Improve the service life, machinability and welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

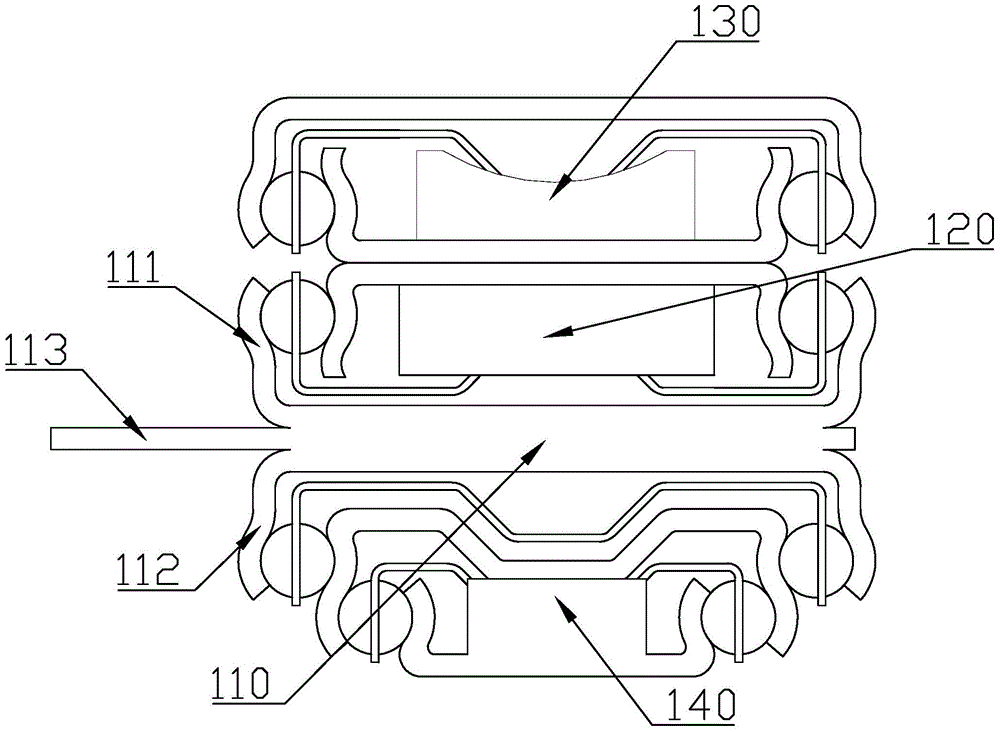

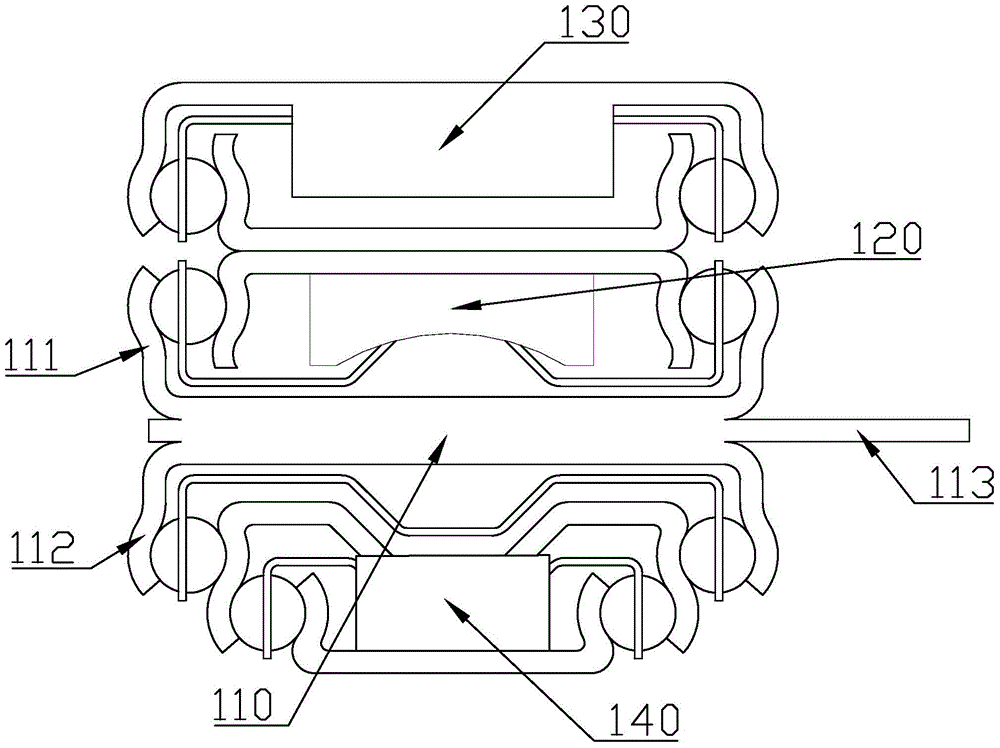

[0024] This embodiment discloses a multi-section splicable slide rail, including a guide rail 110, a first two-section slide rail 120, a second two-section slide rail 130 and a three-section slide rail 140; the guide rail 110 is provided with a first groove 111 and The second groove 112; the guide rail 110 is provided with a fixed block 113; the first two slide rails 120 are movably connected in the first groove 111; the three slide rails 140 are movably connected in the second groove 112; the first two sections The slide rail 120 is fixedly connected with the second two-section slide rail 130 .

[0025] This embodiment only discloses a multi-section splicable slide rail. Based on the concept of the present invention, this embodiment can be correspondingly applied to different types of slide rails such as roller slide rails and slider slide rails. The beneficial effects proposed by the embodiment and the realization of the invention object of the present invention are all with...

Embodiment 2

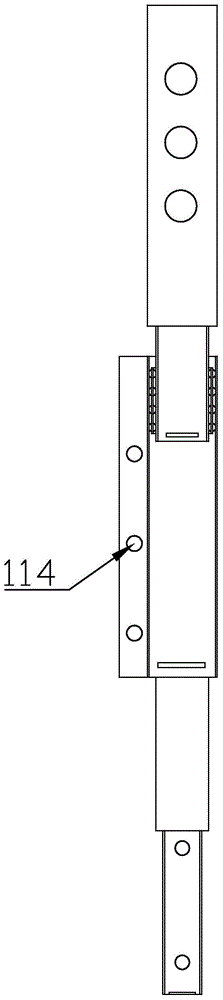

[0027] This embodiment provides a technical solution. The difference from Embodiment 1 is that a fixing hole 114 or a hook 115 is opened on the fixing block 113 for fixing the sliding moving parts, which can be used for screw connection or rivet connection , can also be used for fastening connection, providing multiple options for fixing objects, and improving the flexibility of the present invention.

Embodiment 3

[0029] This embodiment provides a technical solution. The difference from Embodiments 1 and 2 is that the first two-section slide rail 120, the second two-section slide rail 130, and the three-section slide rail 140 are made of steel, and the steel contains The carbon content is low, the comprehensive mechanical properties are high, and the elongation rate is high. Its machining performance and welding performance are good, which effectively improves the service life of the slide rail.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com