Natural circulation thermoregulation autoclaved vulcanizing pot

A technology of natural circulation and vulcanization tank, applied in coating, metal material coating process, heating, etc., can solve the problem of affecting the appearance and even quality of the heated object, affecting the uniform distribution of heat in the autoclave tank, and the running sound of high-pressure fans Large and other problems, so as to avoid the problem of air leakage and oil leakage of the shaft seal, increase the effective use length and avoid the effect of noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

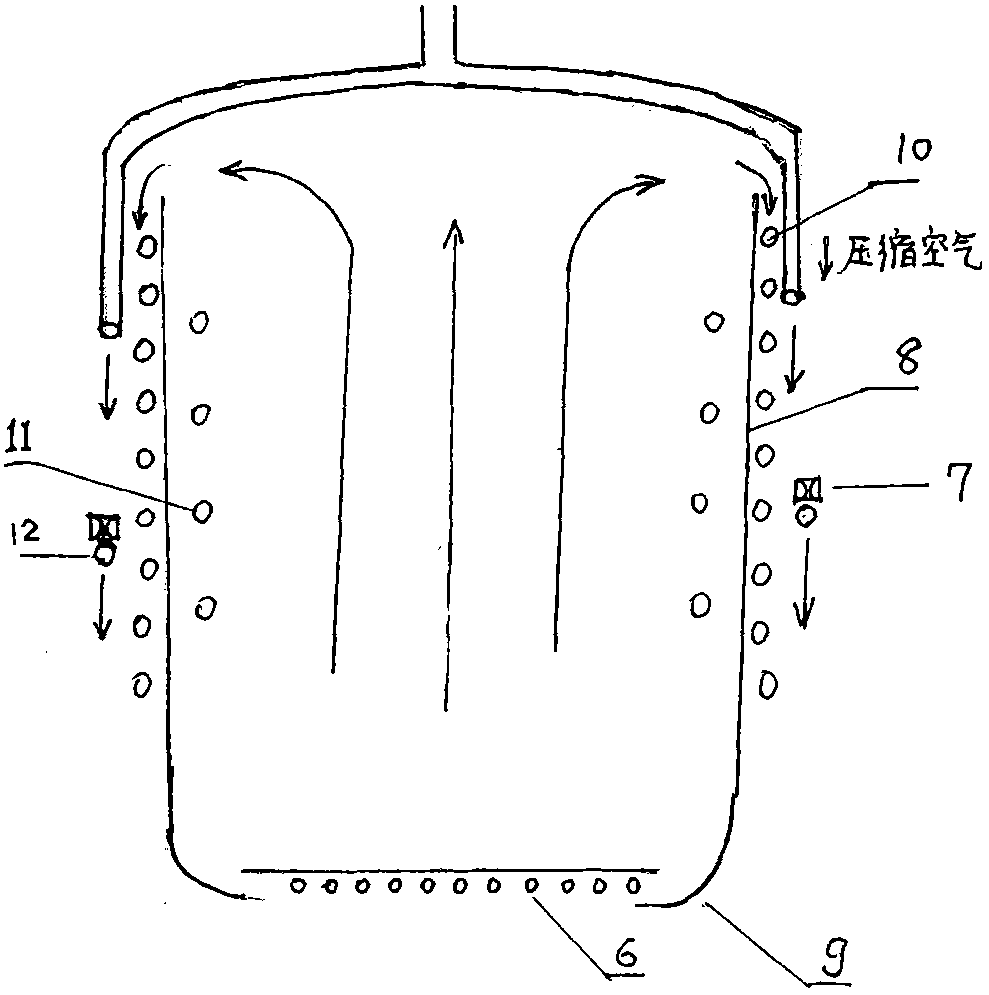

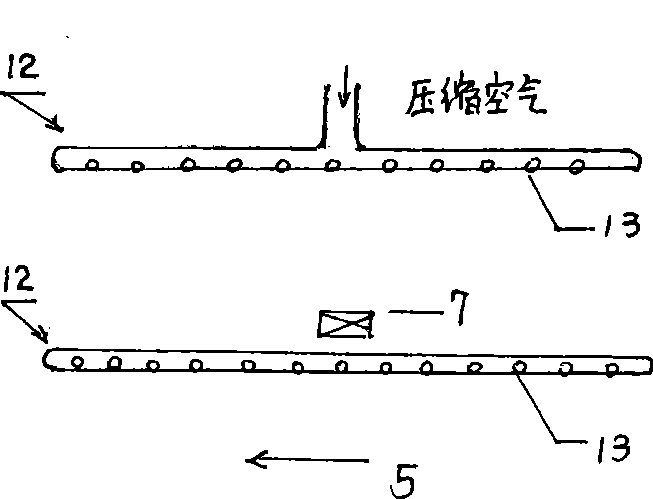

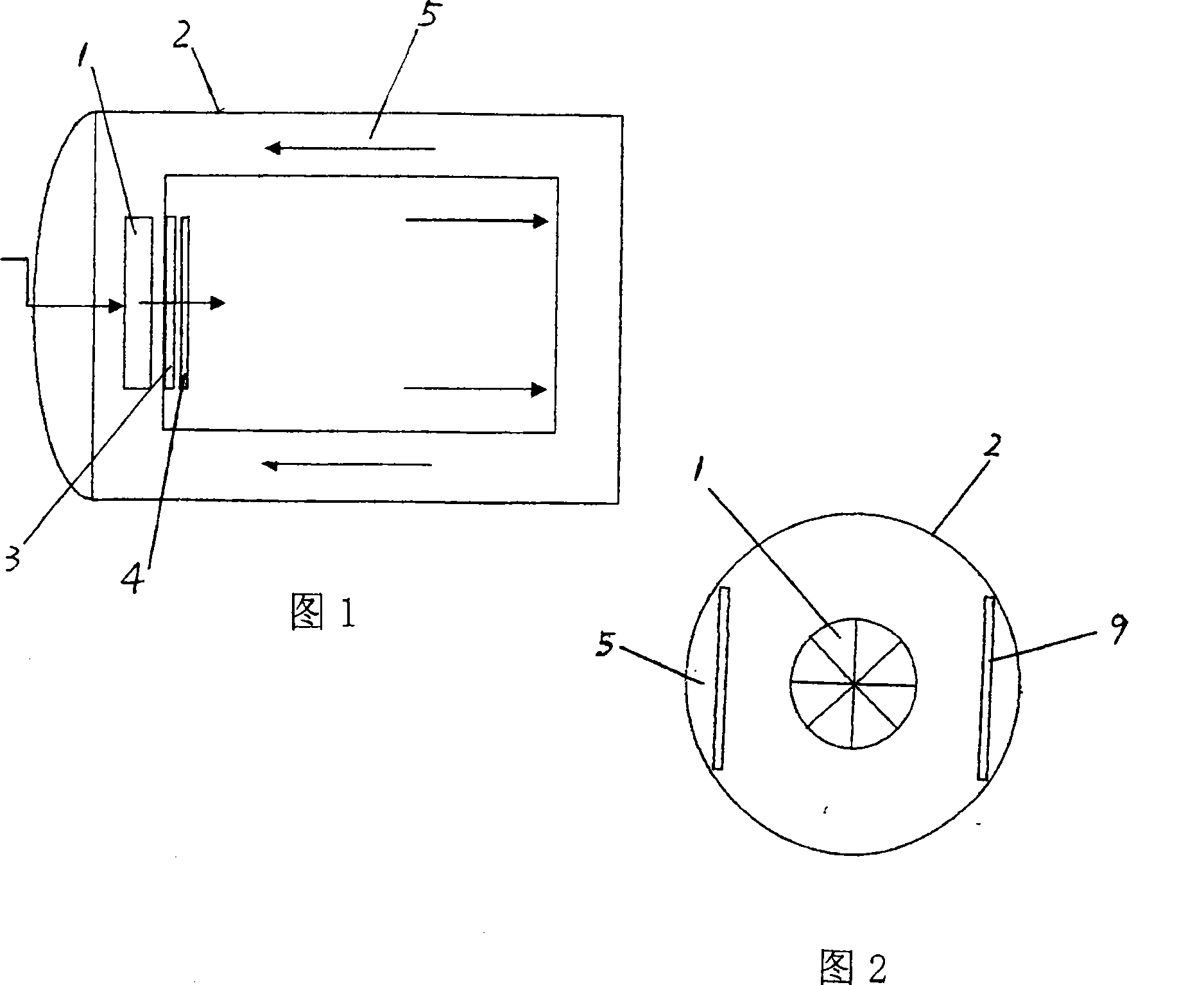

[0025] With the above-mentioned structure, during the heating process, since the heating source is located at the lower part of the autoclave autoclave and the inner side of the windshield, the generated hot air moves upward, forming a low-pressure area at the lower part of the autoclave autoclave, and attracting cold air from the outside of the windshield. The air comes to replenish, and the hot air moves up to the top to form a high-pressure area at the top, pushing the upper air to flow to both sides, and the air on both sides is attracted by the bottom to reduce the pressure, just to attract the upper air to replenish, so the flow is just inside the autoclave vulcanization tank Two longitudinal flow circulation circles are formed around the windshield on both sides. At this time, the heating source just acts as the power source of air circulation, and the air is automatically circulated while heating the material, which solves the problem of uniform distribution of hot air. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com