Non-hyperthermia heat pipe structure

A tube structure and warming technology, applied in indirect heat exchangers, heat exchange equipment, heat exchanger shells, etc., can solve the problems of heat transfer failure of heat pipes, increased manufacturing costs, waste of tube shells, etc., to achieve injection and vacuuming The process is simple, the process and manufacturing costs are reduced, and the effective length of use is improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

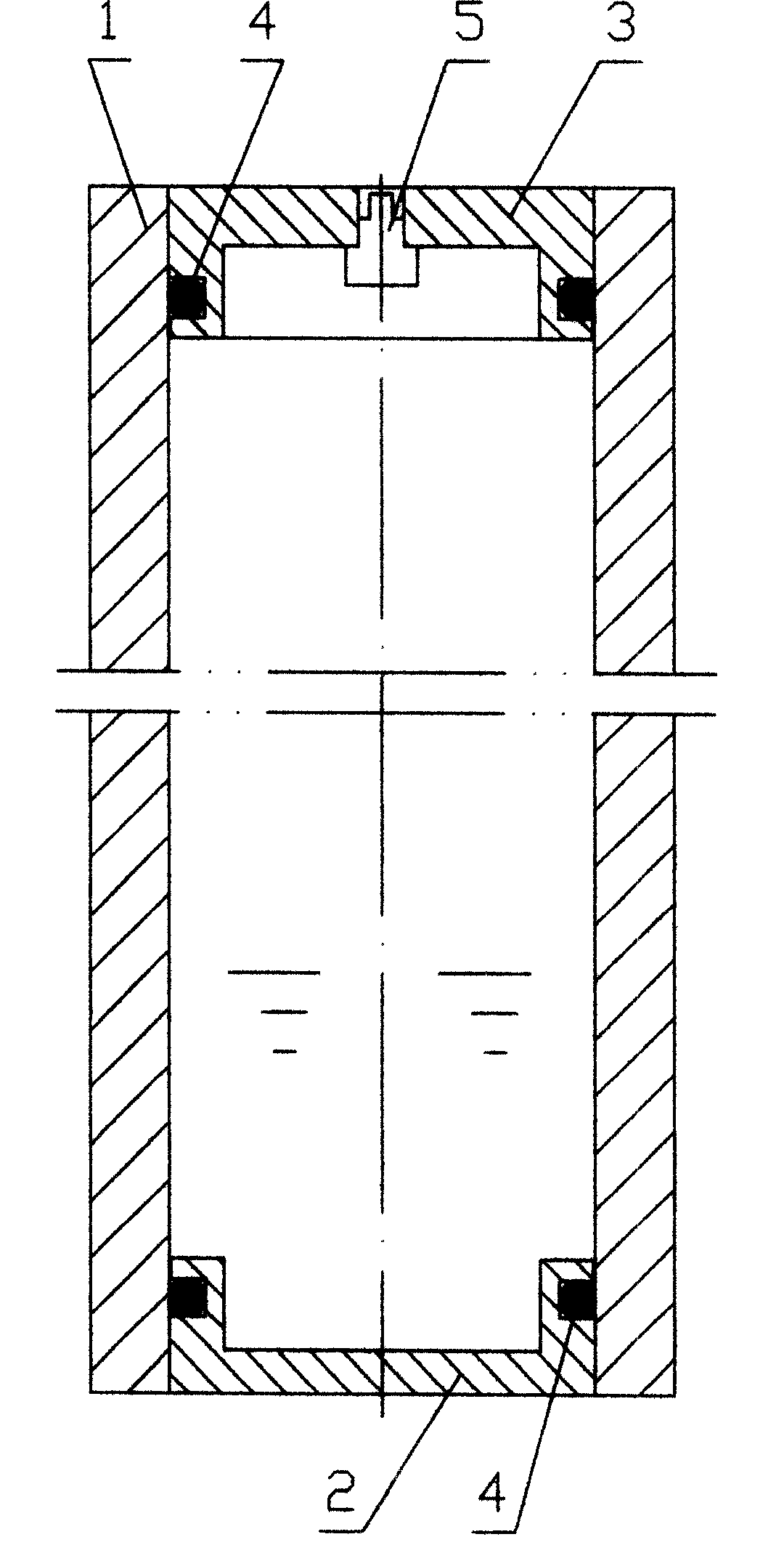

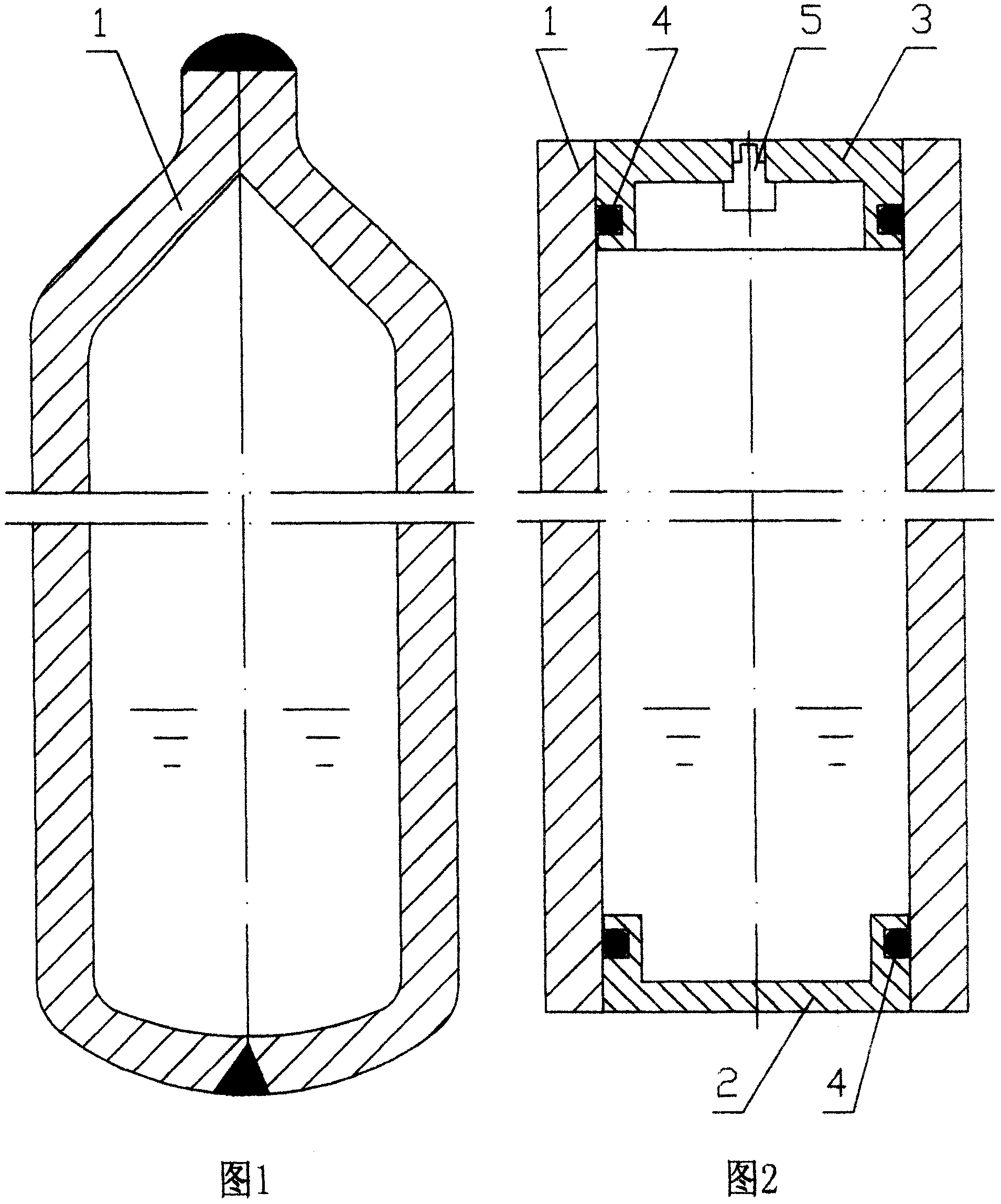

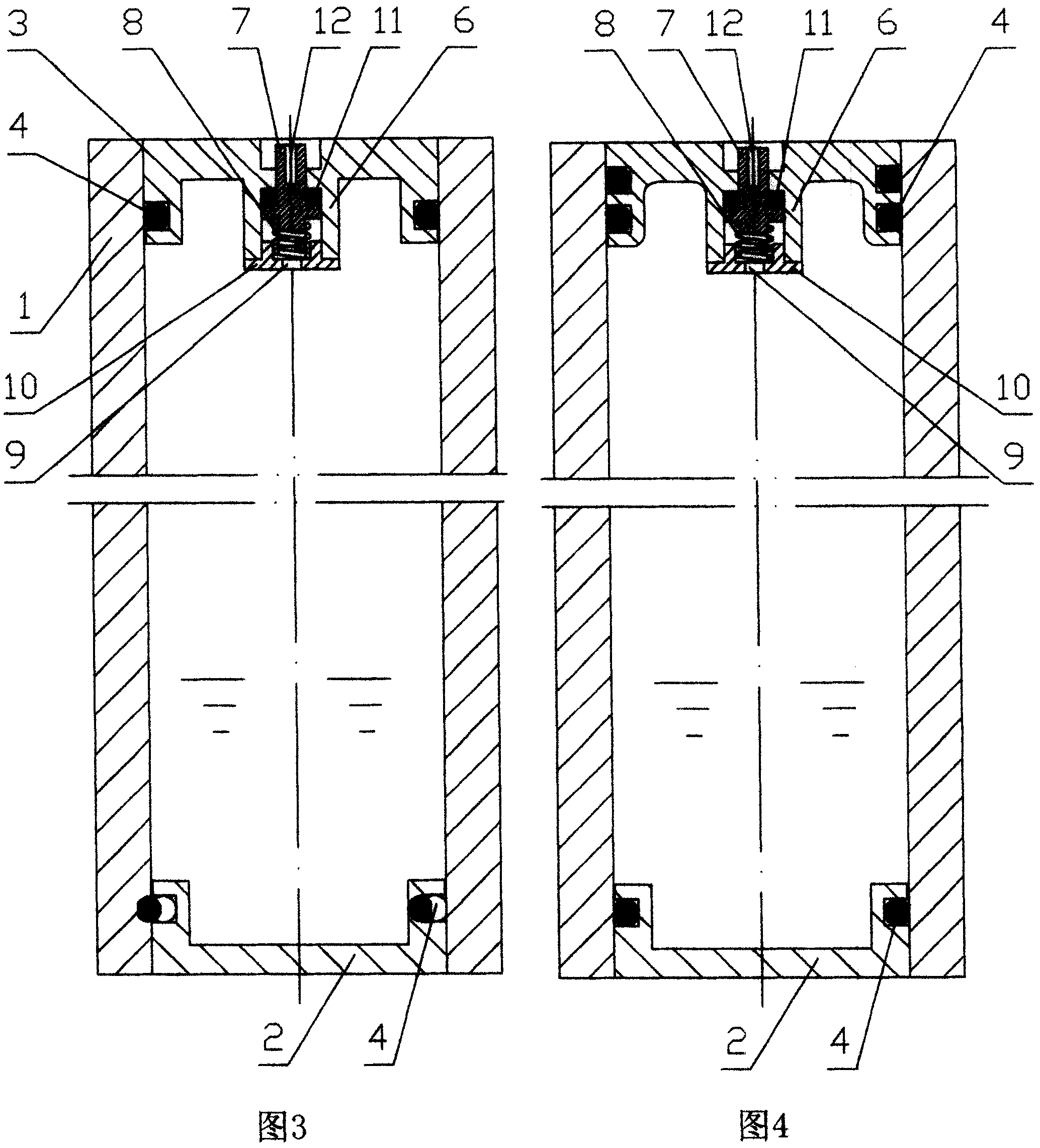

[0014] Referring to accompanying drawing 2, the non-high-temperature heat pipe structure of the present invention adopts a blind plug 2 arranged at one end of the tube shell 1, and a plugging with a one-way controllable conduction valve 5 with a central band for injecting working medium and vacuuming at the other end. 3. The mating surfaces of the blind plug 2 and the plug 3 and the shell 1 are in interference fit contact, and a sealing ring 4 is arranged between the mating surfaces of the blind plug 2 and the plug 3 and the shell 1 .

[0015] The present invention overcomes the traditional design concept of the industry, and realizes the fixing and sealing of the blind plug 2 and the plug 3 and the inner wall of the tube shell 1 by the interference fit contact between the blind plug 2 and the plug 3 and the inner wall of the tube shell 1. A large number of experiments have proved that the use of this structure can fully meet the use requirements of normal temperature heat pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com