Fresh-cut slice processing method of licorice

A processing method and slicing technology, applied in the field of medicine, can solve the problems of lack of temperature parameters in the drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

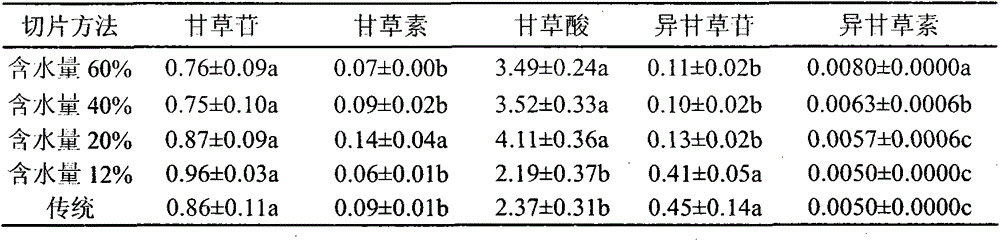

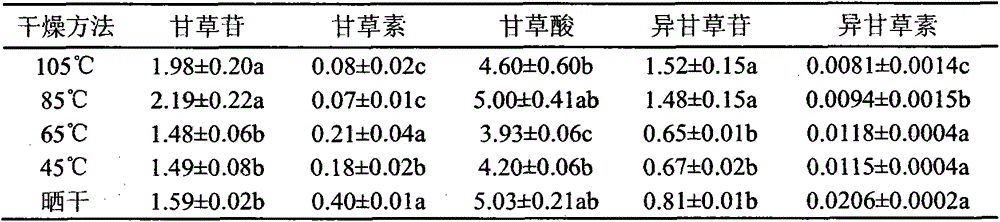

Embodiment 1

[0010] Put the collected raw grass into a drum-type grass washer and rotate for about 10-15 minutes, chop, cut, and cut the washed licorice, and then classify and process into strips, wool grass, knot grass and lumps. When placed under environmental conditions, when the moisture content reaches 60%, cut it into 2-3mm thick slices with a slicer while it is fresh; dry until the moisture content is below 12%; blow the dust and grass residue powder in the slices with wind, etc. After dropping, repack it as required.

Embodiment 2

[0012] Similar to Example 1, the difference is that the collected raw grass is put into a drum-type grass washer and rotated for about 10-15 minutes, and the washed licorice is chopped, cut, and sheared, and then classified into strip grass, wool grass, and knot grass. And lump head, placed under the same environmental conditions after grading, when the water content reaches 40%, cut it into 2-3mm thick slices with a slicer while it is fresh; sun-dried until the water content is below 12%; slice it with wind, etc. After blowing off the dust and grass dregs in the powder, separate packaging as required.

Embodiment 3

[0014] Similar to Example 1, the difference is that the collected raw grass is put into a drum-type grass washer and rotated for about 10-15 minutes, and the washed licorice is chopped, cut, and sheared, and then classified into strip grass, wool grass, and knot grass. And lump head, placed under the same environmental conditions after grading, when the water content reaches 20%, cut it into 2-3mm thick slices with a slicer while it is fresh; sun-dried until the water content is below 12%; use wind etc. to slice After blowing off the dust and grass dregs in the powder, separate packaging as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com