Pulse bag type dust removal self-suction ash discharging device

A technology of pulse bag dust removal and ash discharge device, which is applied to the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles. Facilitate maintenance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

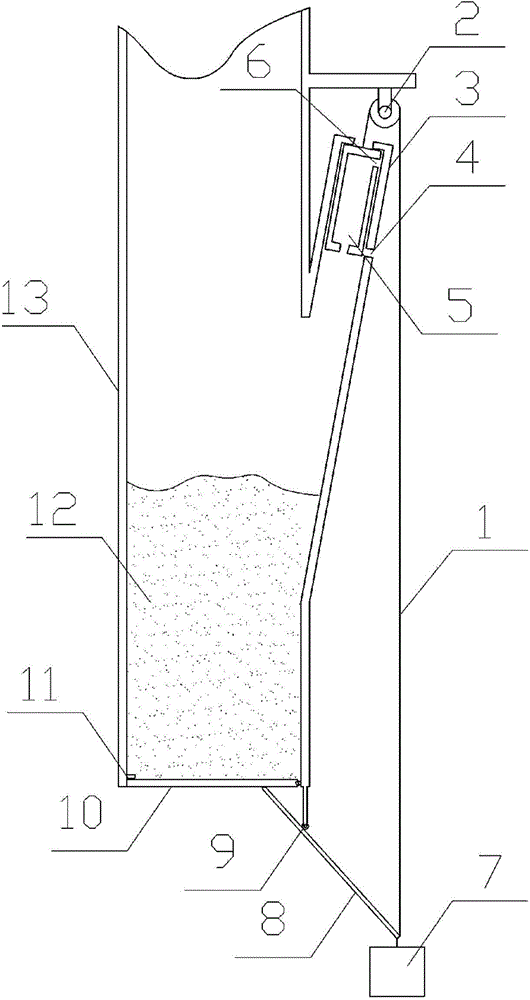

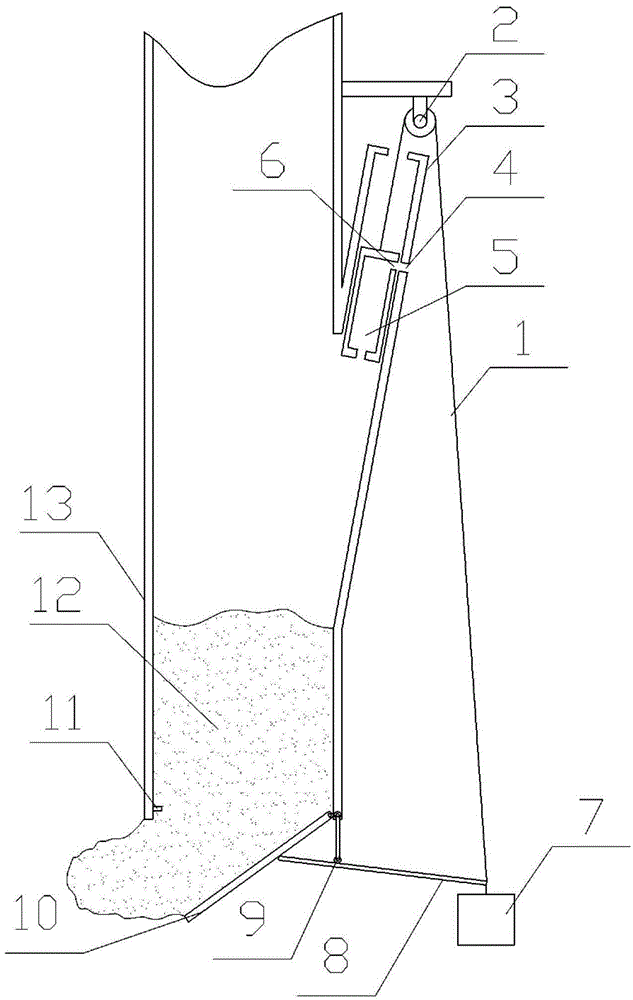

[0009] refer to figure 1 , figure 2 : When the pulse bag dust removal self-priming ash discharge device is in the normal state of non-action, the counterweight (7) simultaneously pulls the steel wire rope (1) and the lever (8) downward, and the steel wire rope (1) passes through the pulley under this force (2) Drive the piston (5) to move upwards, and the lever (8) moves through the lever pin (9), so that one end of the lever (8) pushes up against the gray plate (10), when the gray plate (10) touches the sealing block (11 ) to stop the movement and seal the dust (12) in the ash discharge pipe (13).

[0010] When the suction force of the induced draft fan draws the piston (5) in the suction pipe (3) downward, it overcomes the gravity of the counterweight (7) and pulls up the counterweight (7), and the lever (8) moves accordingly. Press the gray baffle (10) tightly again, the ash baffle (10) is opened, and the dust (12) flows out. When the piston opening (6) set by the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com