Improvement of tial alloy sheath and method of applying it for large deformation rolling

An alloy and sheathing technology is applied in the field of TiAl alloy rolling processing, which can solve the problems of slab cracking and wasting sheathing materials, and achieve the effects of uniform heating, improved thermal insulation effect, and uniform temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

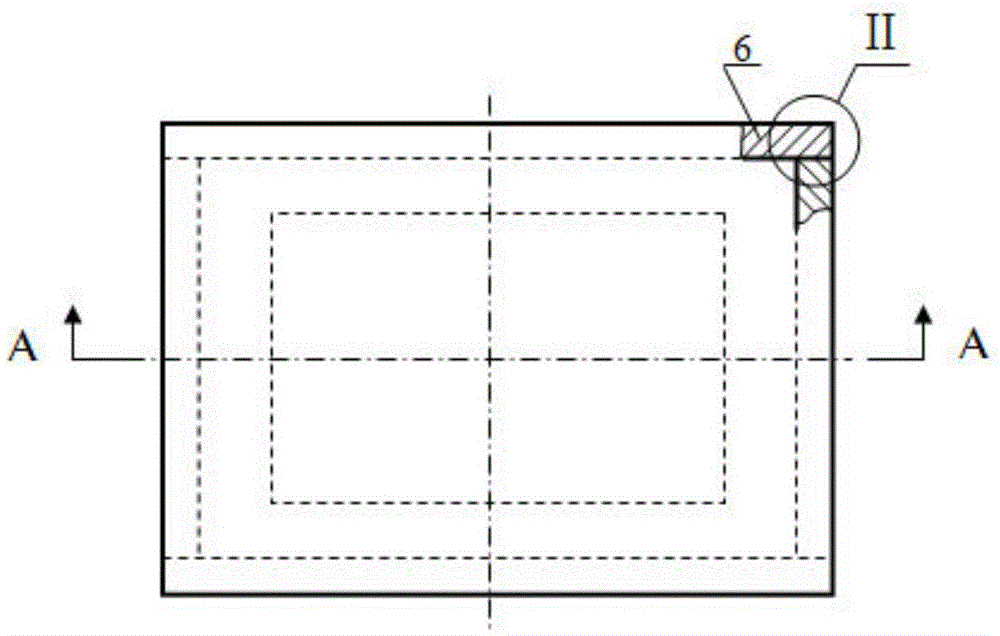

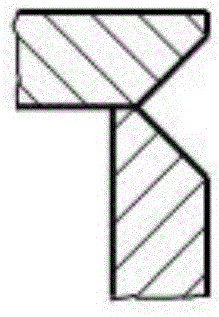

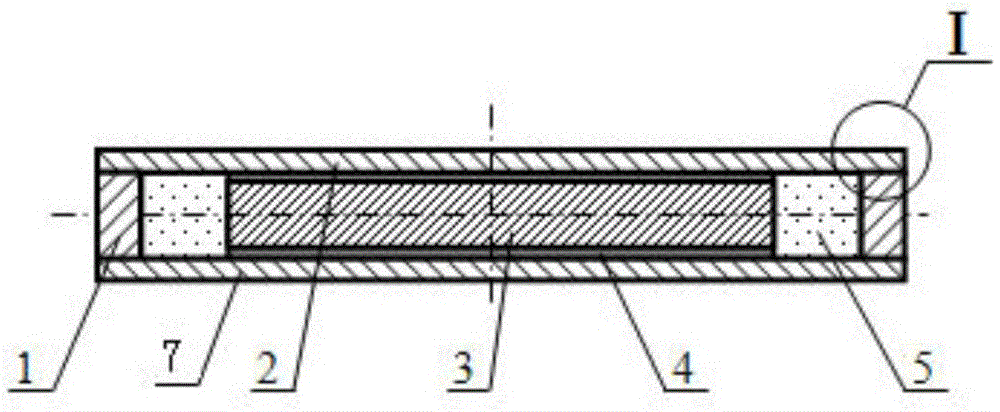

[0021] Embodiment 1: The improved TiAl alloy sheath in this embodiment is composed of a long side enclosure plate 6, a broad side enclosure plate 1, an upper cover plate 2, a lower cover plate 7, a thermal insulation layer 5 and a thermally conductive gasket 4. The long side enclosure plate is composed of 6 and the broad-side enclosing plate 1 to form a rectangular frame, and the upper and lower surfaces of the rectangular frame are welded with an upper cover plate 2 and a lower cover plate 7 to form an envelope cavity, and the TiAl alloy slab 3 placed in the envelope cavity and the width A thermal insulation layer 5 is filled between the side enclosures 1, a thermally conductive gasket 4 is sandwiched between the TiAl alloy slab 3, the upper cover 2 and the lower cover 7, and the thickness of the long side enclosure 6 and the wide side enclosure 1 are the same. The thickness ratio of the upper cover plate 2 to the thickness of the TiAl alloy slab 3 is 0.8-1.2:1, and the thickn...

specific Embodiment approach 2

[0024] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the long side enclosure plate 6, the broad side enclosure plate 1, the upper cover plate 2 and the lower cover plate 7 are all made of 304 stainless steel.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the material of the thermal insulation layer 5 is a zirconium-containing aluminum silicate fiber felt.

[0026] The shape of the workpiece to be processed is a cuboid. When rolling the sheet at high temperature, the heat dissipation rate at the intersection of the two planes of the workpiece is much greater than the heat dissipation rate in the normal direction of the workpiece plane. Therefore, in the vertical section of the workpiece, the distribution of the temperature field is characterized by a gradual decrease in temperature from the inside to the outside, and the isotherm is elliptical. When the low temperature zone lower than the rolling temperature is close to the side surface of the slab, the slab working surface and a part of the cladding material close to the working surface are still in the rolling sheet temperature zone. Therefore, the high temperature resistant aluminum si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com