A wire cutting device for aramid fiber after stripping the optical fiber jumper

An optical fiber jumper and aramid wire technology, which is applied in the field of the aramid wire cutting device after the optical fiber jumper is stripped, can solve the problems of high labor cost, difficult to guarantee consistency, low production efficiency, etc., and achieves a high degree of automation , Increase the running stability, the effect of good cutting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

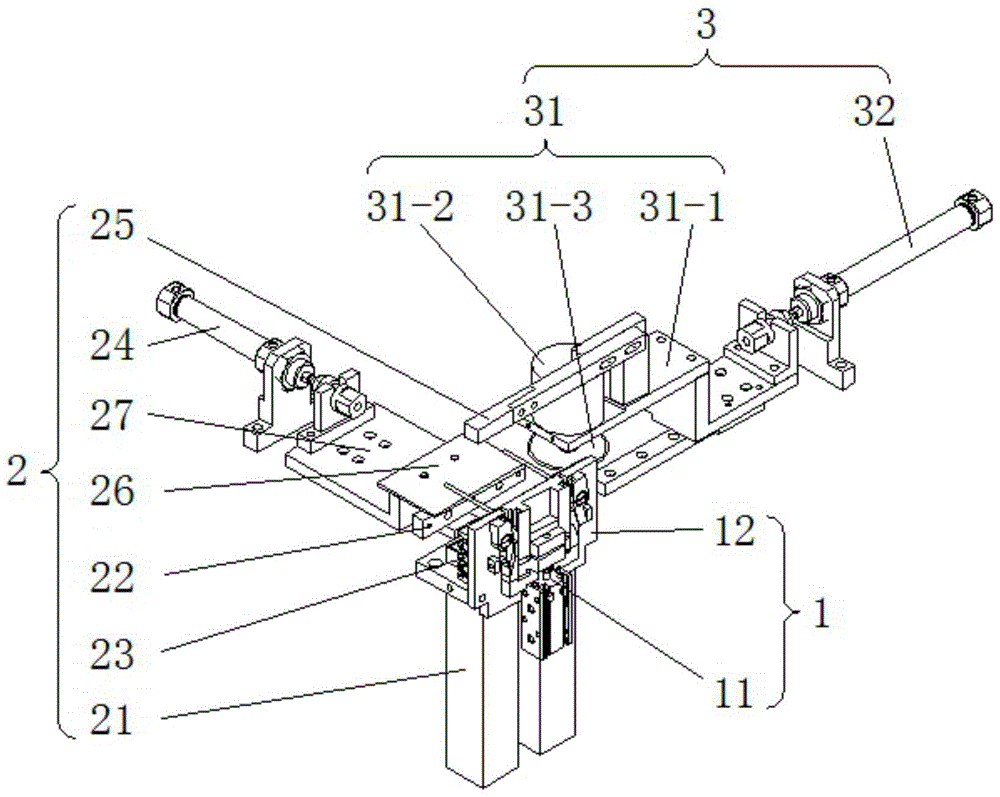

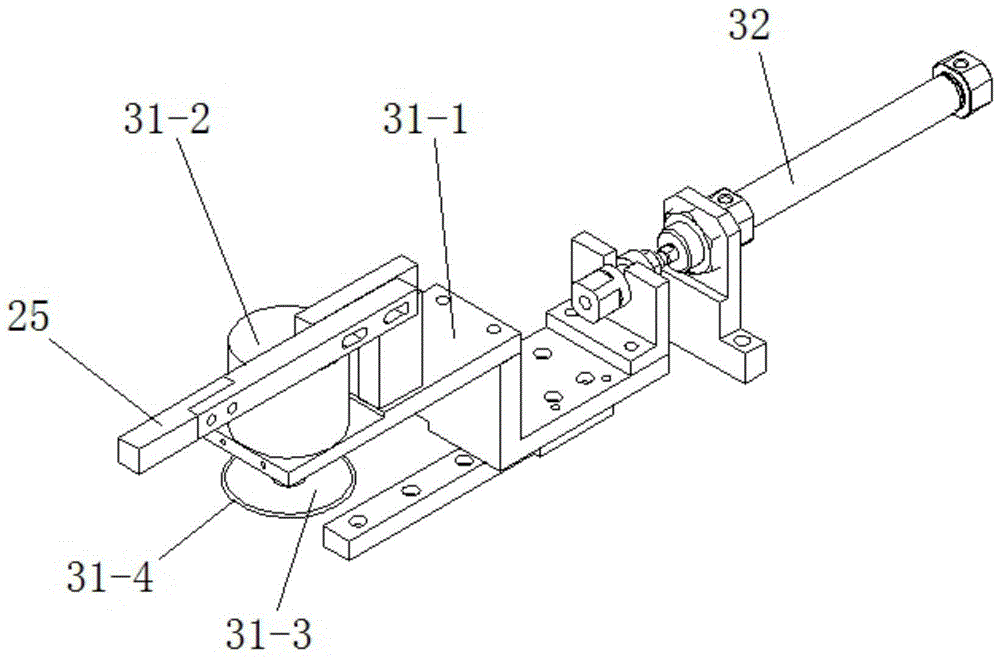

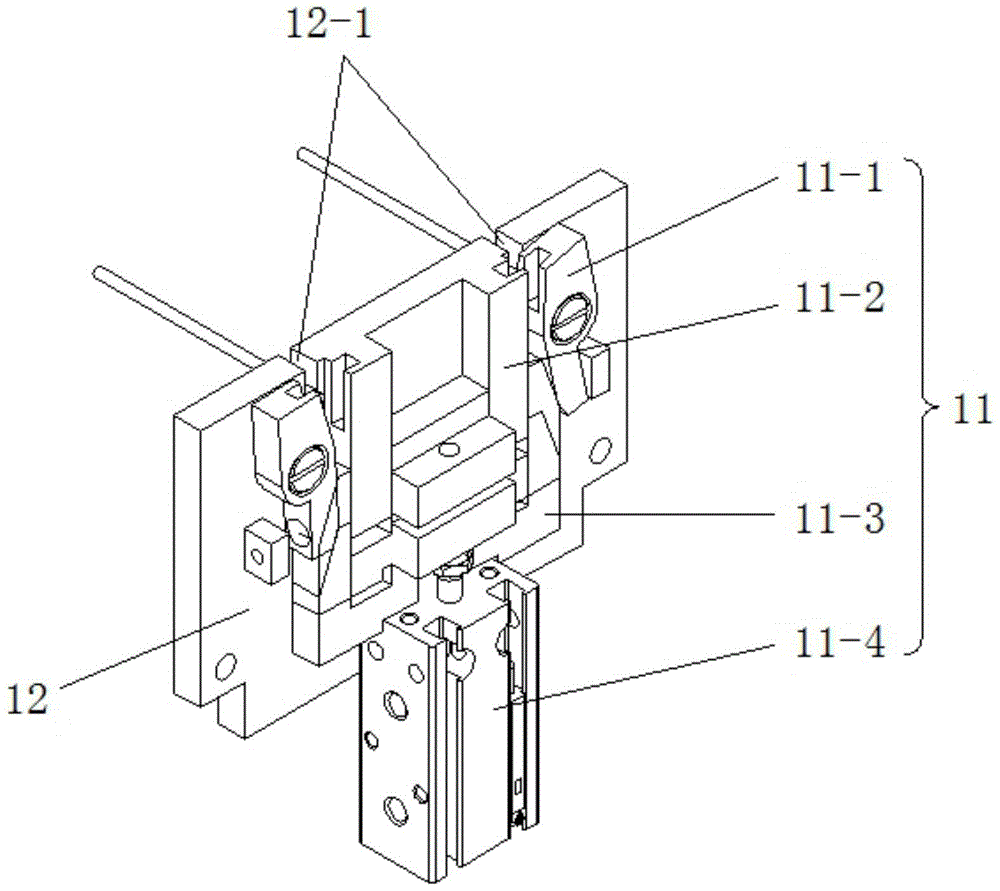

[0021] See Figure 1 to Figure 4 , the present invention includes a mounting plate, the mounting plate is provided with a clamping mechanism 1 for clamping the optical fiber, a wire management mechanism 2 for gathering and fixing the aramid wire at the stripping part of the optical fiber and a wire trimming mechanism 3 for cutting the aramid wire The wire management mechanism 2 includes an air suction pipeline 21, a pressure line moving plate 22, a pressure line fixed plate 23, a pressure line cylinder 24, an air blowing pipeline 25, a pressure line tension plate 26 and a spring assembly; the air suction pipeline 21 is arranged below the optical fiber stripping place and between the crimping moving plate 22 and the crimping fixed plate 23; the crimping moving plate 22 and the crimping fixed plate 23 are located at both axial ends of the fiber stripping place and at Below; the spring assembly includes a connecting plate 27, a moving plate connecting rod 28 and a return spring; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com