High-efficiency circuit board cutting machine

A plate cutting machine, high-efficiency technology, applied in metal processing, etc., can solve the problems of unfavorable production efficiency and cost reduction, restricting the survival and development of enterprises, and poor cutting accuracy, so as to increase competitiveness, improve work efficiency, and cut fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

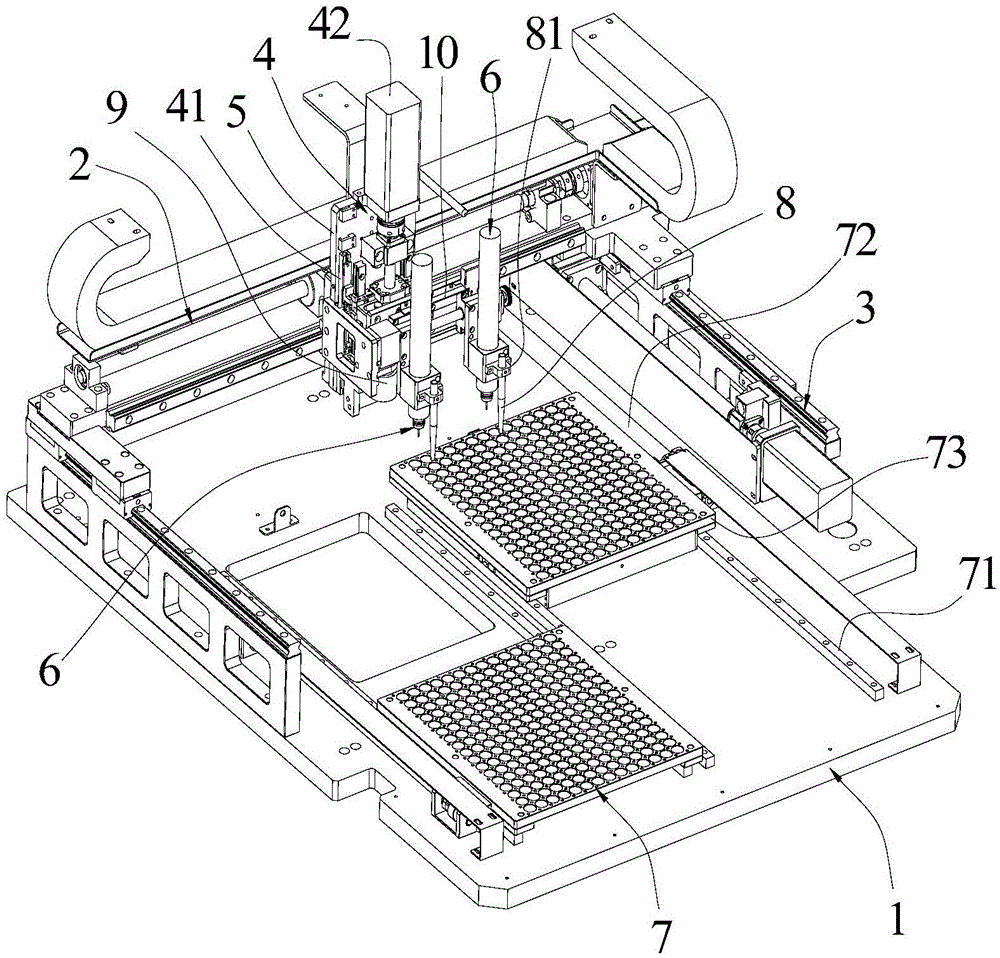

[0016] Example: see figure 1 , a high-efficiency circuit board cutting machine provided in this embodiment includes a workbench 1, an X-axis slide rail kit 2, a Y-axis slide rail kit 3, a Z-axis slide rail kit 4, and a sliding tool holder 5. A horizontal mounting plate 10 and two cutting heads 6 arranged side by side on the horizontal mounting plate 10, two universal trays 7 that can reciprocate and slide along the Y-axis direction are arranged side by side in the middle of the workbench 1, and the Y-axis The slide rail set 3 is arranged on one side of the workbench 1, the X-axis slide rail set 2 is movably arranged on the Y-axis slide rail set 3, and the sliding tool holder 5 is movably arranged on the X-axis slide rail On the kit 2 , the transverse mounting plate 10 is arranged on the sliding tool seat 5 through the Z-axis slide rail kit 4 . In other embodiments, the number of cutting heads 6 can be set accordingly according to the required cutting efficiency, such as setti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com