Plastic pulverizer

A pulverizer, plastic technology, applied in plastic recycling, recycling technology, grain processing and other directions, can solve problems such as affecting the purity of plastic particles, polluting the environment, affecting health, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

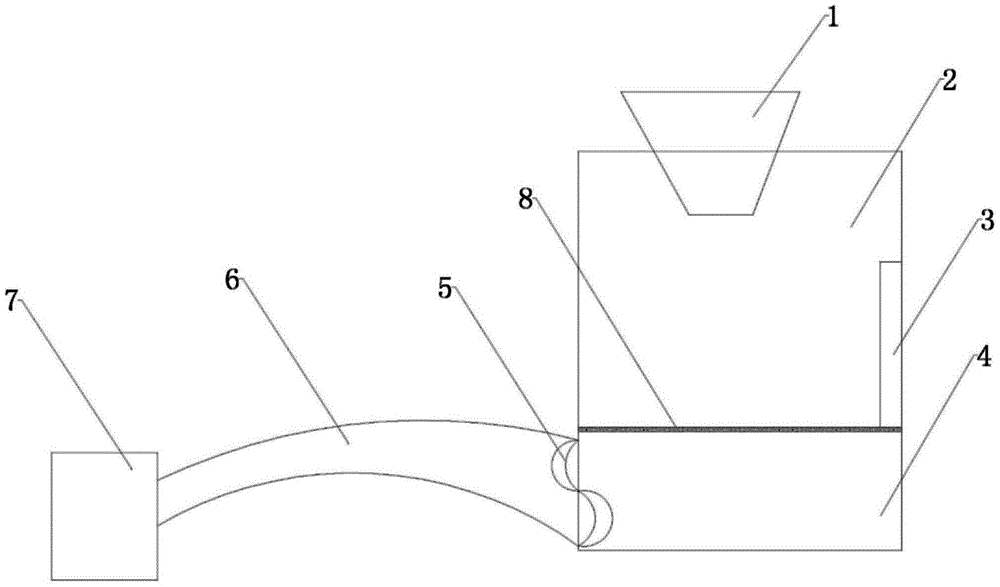

[0009] according to figure 1 The shown plastic pulverizer has a feed port 1, a crushing bin 2, a discharge port 3, a dust bin 4, a fan 5, a dust pipeline 6, a recovery bin 7 and a filter screen 8; the feed port 1 is installed in The upper part of the crushing bin 2, the discharge port 3 is installed on the side wall of the crushing bin 2; the dust bin 4 is located at the bottom of the crushing bin 2, and the crushing bin 2 and the dust bin 4 are connected and communicated through the filter screen 8; A fan 5 is installed on the side wall of the dust bin 4 , and a dust pipe 6 is connected to the fan 5 , and the other end of the dust pipe 6 is connected to a recovery bin 7 .

[0010] When in use, large plastic recycling parts, such as defective products, leftover materials, etc., are put into the feed port 1, and are crushed into plastic particles in the crushing bin 2, and the plastic particles can be taken out from the discharge port 3; during the crushing process , can produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com