Composite wear-resisting plate

A wear-resistant plate and substrate technology, applied in the field of wear-resistant plates, can solve the problems of complex manufacturing process, increased chain wear, poor wear resistance, etc., and achieve the effects of simple processing, extended service life and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

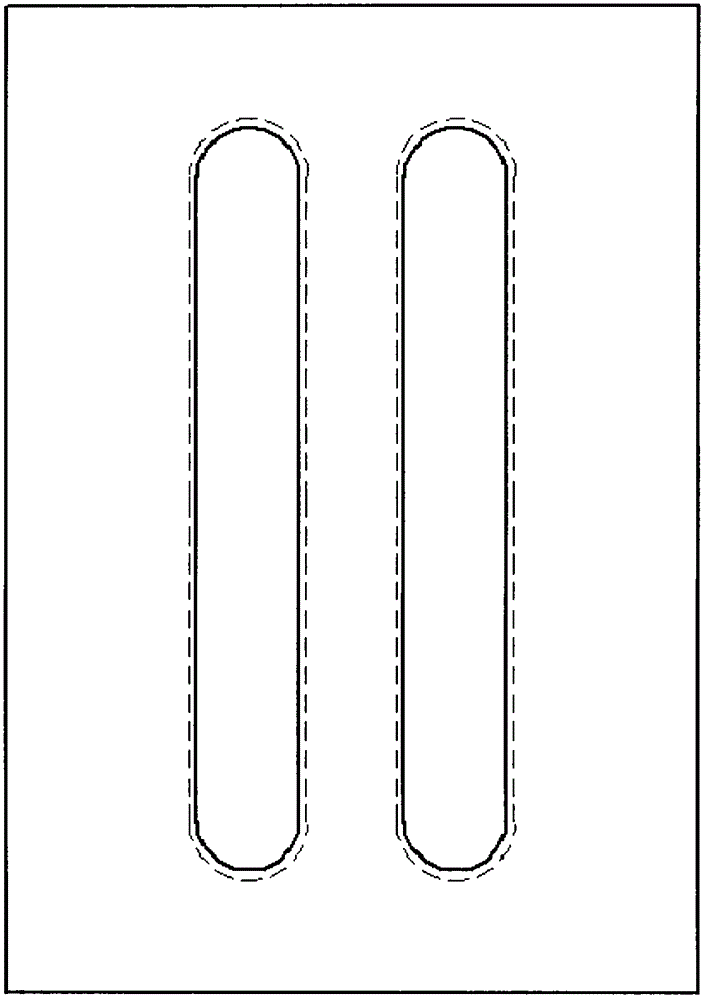

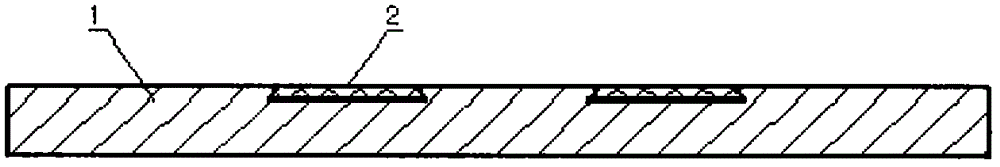

[0010] Such as figure 1 , figure 2 The plate in the groove shown in the middle (an example of a composite wear-resistant plate) includes a wear-resistant plate substrate 1 and a polyurethane wear-resistant layer 2 . The material of the base plate is Hardox450 wear-resistant plate with a thickness of 40mm; dovetail grooves are processed on the working surface of the base plate at the chain path (that is, the most seriously worn part of the middle plate). The urethane wear-resistant layer is cast in the form of hot fluid in the base plate embedding groove, and the pouring temperature is 250-300°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com