Paddle strain gauge arranging and decoupling method

A technology of strain gauges and blades, applied in the field of helicopter structural testing, can solve problems such as insufficient timeliness, achieve the effects of saving workload, improving work efficiency, and reducing processing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Below with the certain helicopter rotor blade of load test as example, describe the present invention in detail:

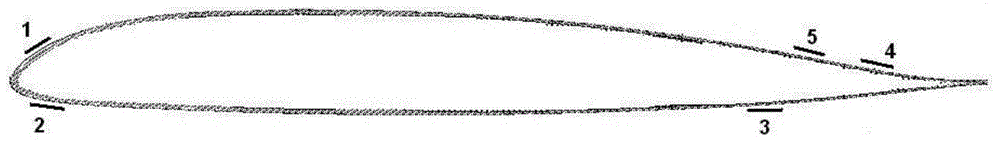

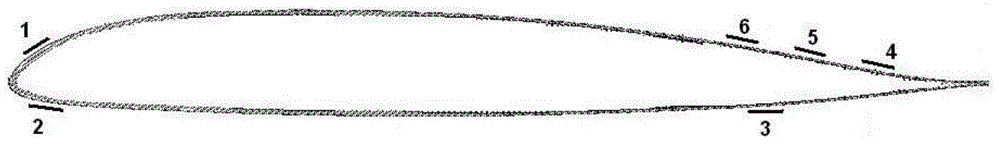

[0046] The first step is to paste 5 strain gauges on the section of the tested blade, such as figure 1 shown. Wherein, the first strain gauge 1 and the second strain gauge 2 are attached to the leading edge of the tested blade, and the third strain gauge 3, the fourth strain gauge 4 and the fifth strain gauge 5 are attached to the trailing edge of the tested blade, All five strain gauges should be attached to the same material of the tested blade;

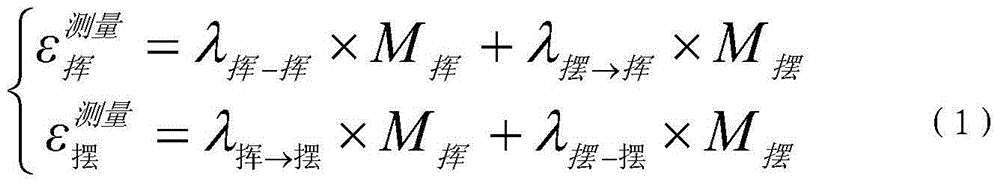

[0047] In the second step, the flapping moment M is applied to the section of the tested blade 挥 =20kg×3490mm, the measured strain values of the five strain gauges are ε 挥1 , ε 挥2 , ε 挥3 , ε 挥4 and ε 挥5 , see Table 1 for specific data, and calculate: See Table 3 for specific data;

[0048] Table 1: Output values of each strain gauge with a swinging load applied

[0049]

[0050] The third step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com