Multifunctional film-free electrolytic boiled water machine

A membrane electrolysis and multi-functional technology, applied in water treatment sites, water/sewage treatment, water/sewage treatment equipment, etc., can solve the problem of large water temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

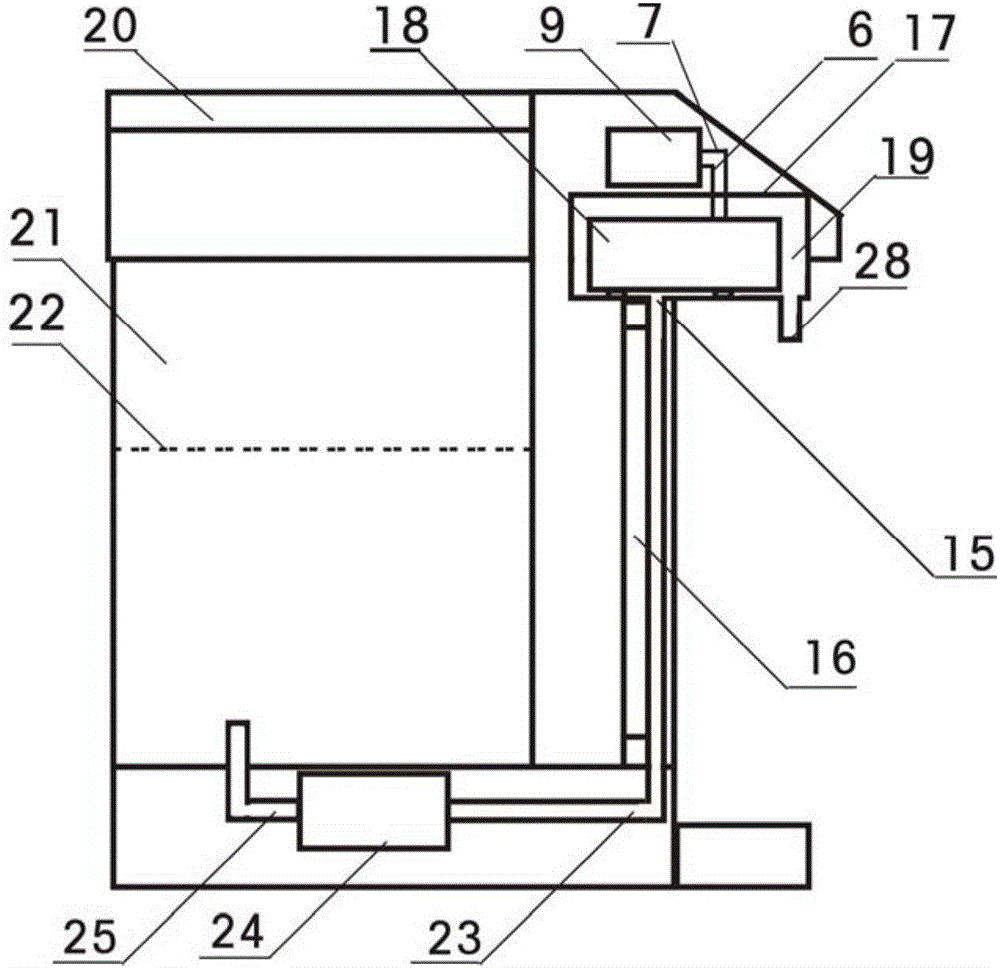

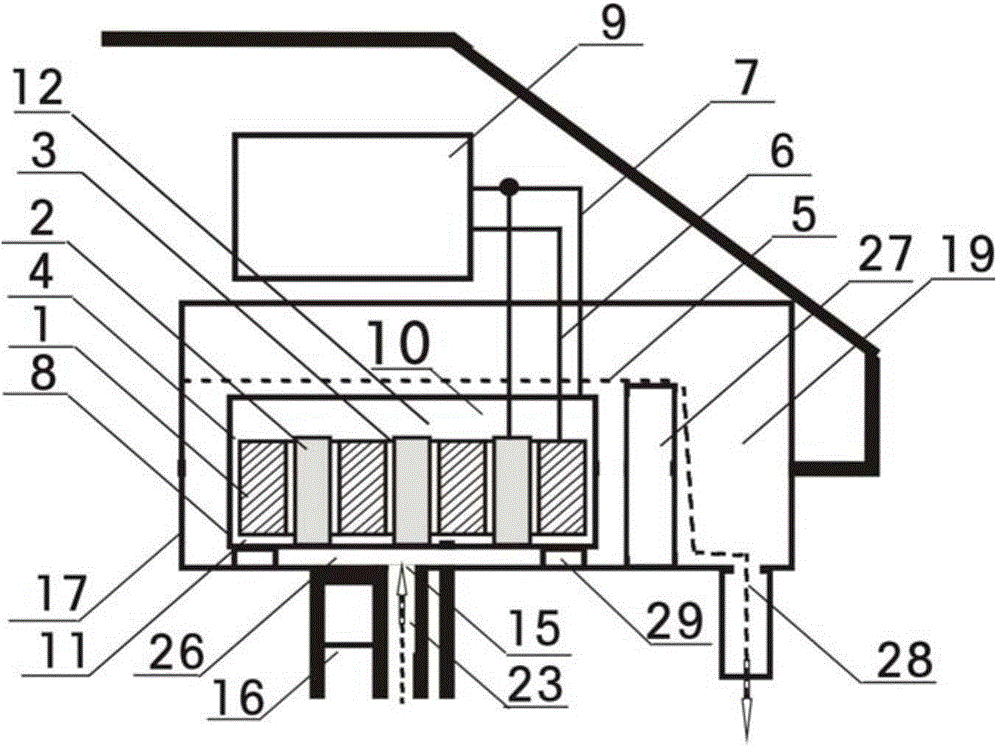

[0031] Such as Figure 1A , a multifunctional membraneless electrolytic water boiler, characterized in that it includes a water-filled container 21, a container cover 20, and 22 is a schematic line for the water level of the container; an electric heater 15 that can heat water to boiling; an electrolytic power supply 9; There is an electrolytic cell 10 with a water inlet and a water outlet; the electrolytic cell partition plate 11 divides the electrolytic cell into an electrolytic electrode assembly area 18 and an electrolytic cell water outlet area 19; an electrolytic electrode assembly 18 for electrolyzing water is housed in the electrolytic cell (the internal structure is detailed See Figure 1B and related descriptions); the water in the container 21 can be pumped to the electrolytic water tank 17 and the electrolytic cell 10 by the electric pump 24 through the outlet pipe 25 at the bottom of the container and the electric pump outlet pipe 23; the vertical part of the pipel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com