Solvent-free epoxy coating

An epoxy coating, solvent-free technology, applied in the direction of epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as non-compliance with environmental protection, and achieve good construction safety and environmental protection, high safety, and components The effect of formulation science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

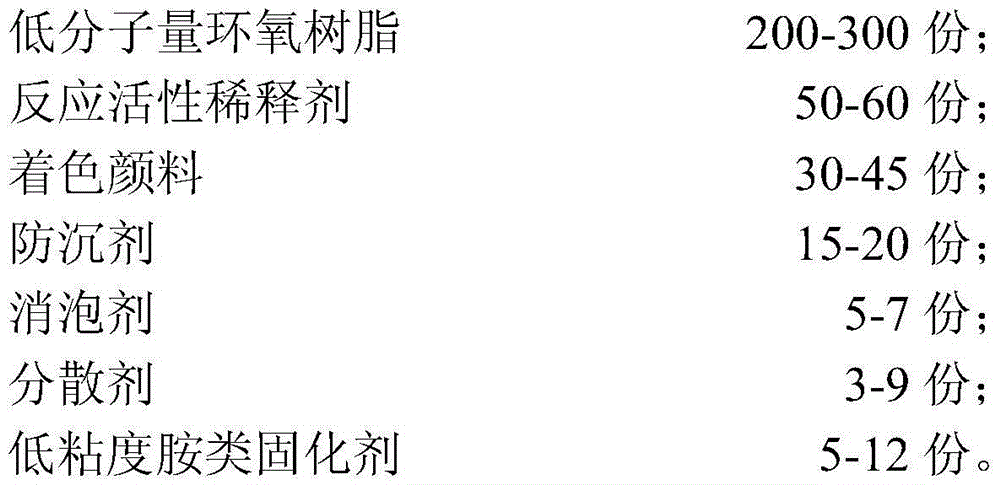

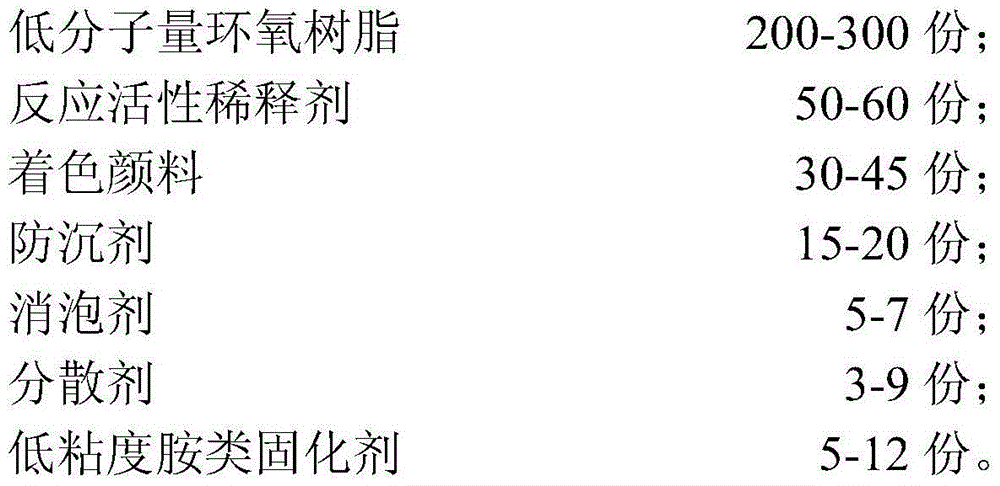

[0013] A solvent-free epoxy coating, the components of the solvent-free epoxy coating and their weight / number ratios are respectively: 200Kg of low molecular weight epoxy resin; 50-60Kg of reactive diluent; 30Kg of coloring pigment; 15Kg of anti-settling agent ; Defoamer 5Kg; Dispersant 3Kg; Low viscosity amine curing agent 5Kg. The low molecular weight epoxy resin is bisphenol F epoxy resin. Low viscosity amine curing agent is a low viscosity phenolic modified amine curing agent.

Embodiment 2

[0015] A solvent-free epoxy coating, the components of the solvent-free epoxy coating and their weight / number ratios are respectively: 300Kg of low molecular weight epoxy resin; 60Kg of reactive diluent; 45Kg of coloring pigment; 20Kg of anti-settling agent; Foaming agent 7Kg; dispersant 9Kg; low viscosity amine curing agent 12Kg. The low molecular weight epoxy resin is bisphenol F epoxy resin. Low viscosity amine curing agent is a low viscosity phenolic modified amine curing agent.

Embodiment 3

[0017] A solvent-free epoxy coating, the components of the solvent-free epoxy coating and their weight / number ratios are respectively: 240Kg of low molecular weight epoxy resin; 55Kg of reactive diluent; 38Kg of coloring pigment; 18Kg of anti-settling agent; Foaming agent 6Kg; dispersant 7Kg; low viscosity amine curing agent 8Kg. The low molecular weight epoxy resin is bisphenol F epoxy resin. Low viscosity amine curing agent is a low viscosity phenolic modified amine curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com