Urethane-based pressure-sensitive adhesive and surface protective film using the pressure-sensitive adhesive

A technology based on pressure-sensitive adhesives and polyurethane-based resins, used in polyurea/polyurethane adhesives, adhesives, non-polymer adhesive additives, etc., can solve the problems of liquid crystal molecular orientation loss and panel loss, and achieve antistatic The effect of excellent performance, adhesive residue prevention performance and excellent reworkability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

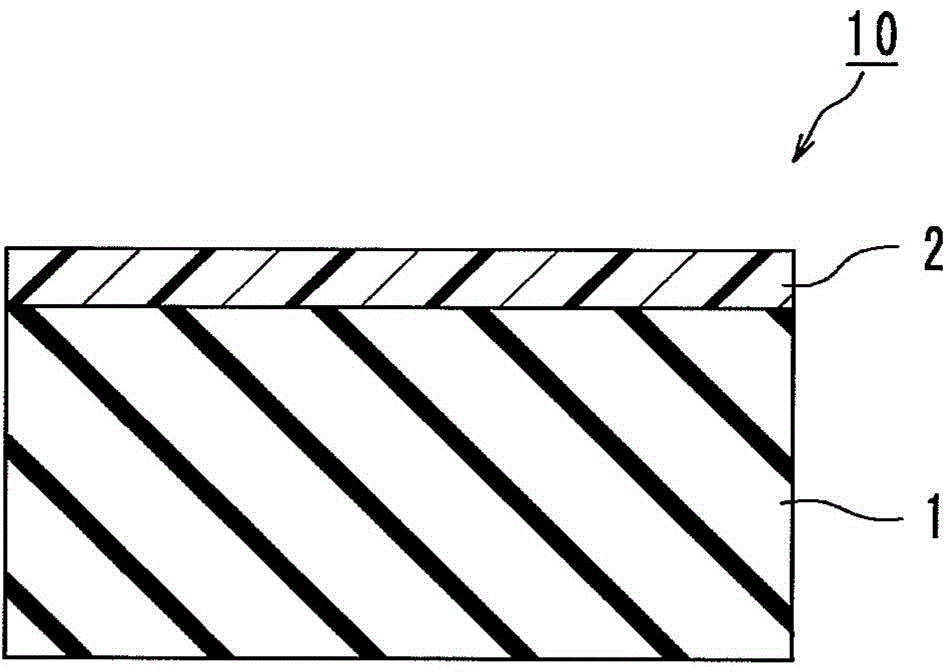

Image

Examples

Embodiment 1

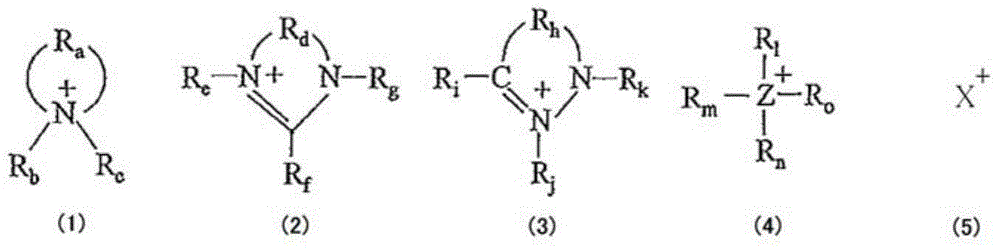

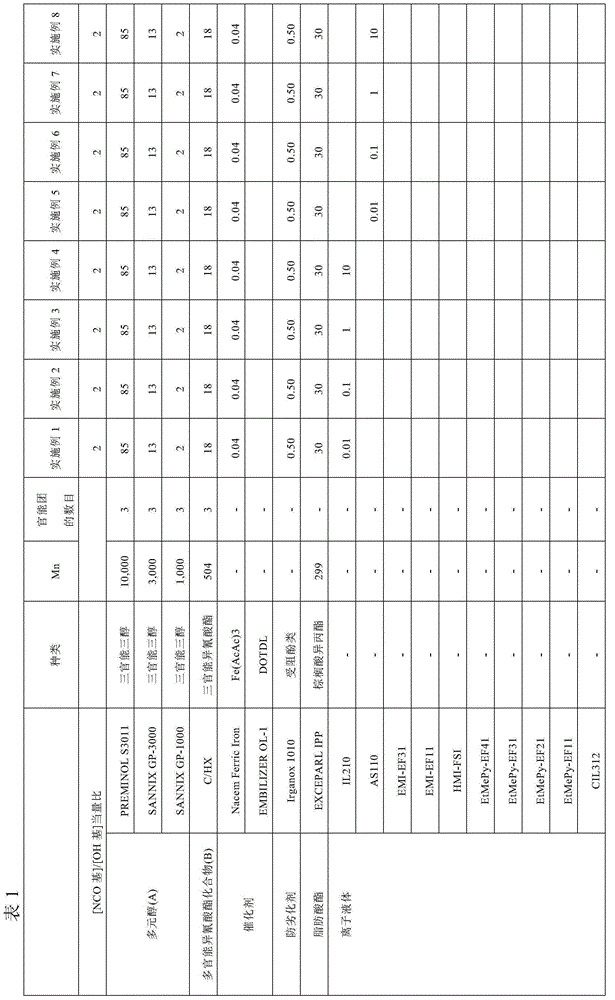

[0225] As the polyol (A), 85 parts by weight of a polyol PREMINOL S3011 having three OH groups (manufactured by ASAHI GLASS CO., LTD., Mn=10,000), 13 parts by weight of a polyol having three OH group polyol SANNIX GP-3000 (manufactured by Sanyo Chemical Industries, Ltd., Mn=3,000) and 2 parts by weight of polyol SANNIX GP-1000 having three OH groups (manufactured by Sanyo Kasei Kogyo Co., Ltd., Mn=1,000), 18 parts by weight of a polyfunctional alicyclic isocyanate compound CORONATE HX (manufactured by Nippon Polyurethane Industry CO., Ltd.) as the polyfunctional isocyanate compound (B) Manufactured), 0.04 parts by weight of catalyst (manufactured by NIHON KAGAKU SANGYO CO., LTD., trade name: Nacem Ferric Iron), 0.50 parts by weight of Irganox 1010 (manufactured by BASF) as an anti-deterioration agent ), 30 parts by weight of fatty acid ester (isopropyl palmitate, manufactured by Kao Corporation (Kao Corporation), trade name: EXCEPARL IPP, Mn=299), 0.01 parts by weight of 1-eth...

Embodiment 2

[0230] A pressure-sensitive adhesive layer formed of a polyurethane-based pressure-sensitive adhesive (2) was produced on a substrate in the same manner as in Example 1, except that 1-ethyl-3-methylimidazole The amount of bis(trifluoromethylsulfonyl)imide was changed to 0.1 parts by weight.

[0231] Then, the silicone-treated surface of a base material formed of polyester resin having a thickness of 25 μm, one surface of which was silicone-treated, was attached to the surface of the pressure-sensitive adhesive layer to provide a surface protective film (2).

[0232] Table 1 shows the evaluation results.

Embodiment 3

[0234] A pressure-sensitive adhesive layer formed of a polyurethane-based pressure-sensitive adhesive (3) was produced on a substrate in the same manner as in Example 1, except that 1-ethyl-3-methylimidazole The amount of bis(trifluoromethylsulfonyl)imide was changed to 1 part by weight.

[0235] Then, the silicone-treated surface of a base material formed of polyester resin having a thickness of 25 μm, one surface of which was silicone-treated, was attached to the surface of the pressure-sensitive adhesive layer to provide a surface protective film (3).

[0236] Table 1 shows the evaluation results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com