Composite coating for gas turbine blade

A technology for gas turbine blades and composite coatings, applied in coatings, metal material coating processes, superimposed layer plating, etc., can solve problems such as damage, affecting the stability of nanocrystalline layer structures, and lack of aluminum elements, and achieve improved Stability, avoid premature peeling failure, prevent falling off effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this embodiment, the MGA1400 superalloy blade used by Mitsubishi Gas Turbine is used as the superalloy substrate 1, and its specific composition (weight percentage) is as follows:

[0026] element

co

Cr

Mo

W

Al

Ti

Ta

C

Zr

wt%

10

14

1.5

4

4

3

5

0.08

0.03

[0027] (Table 1)

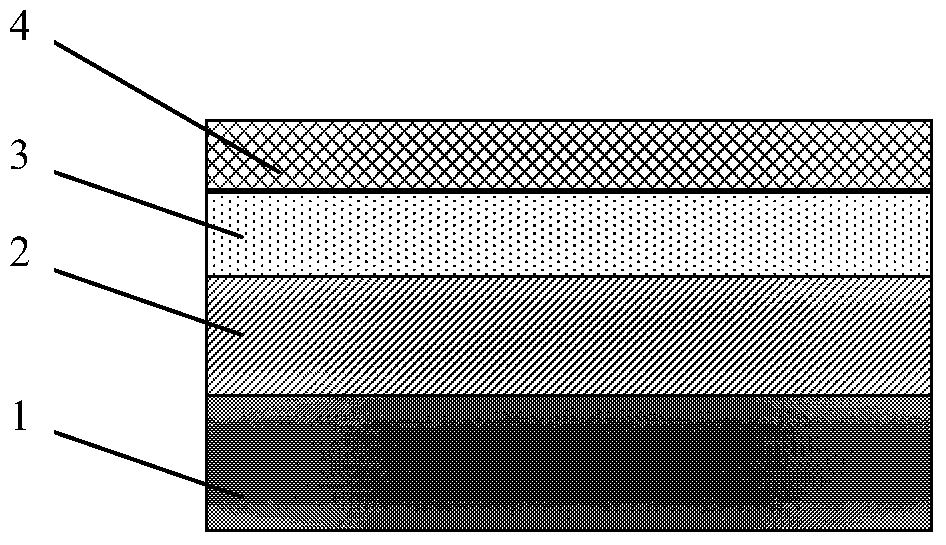

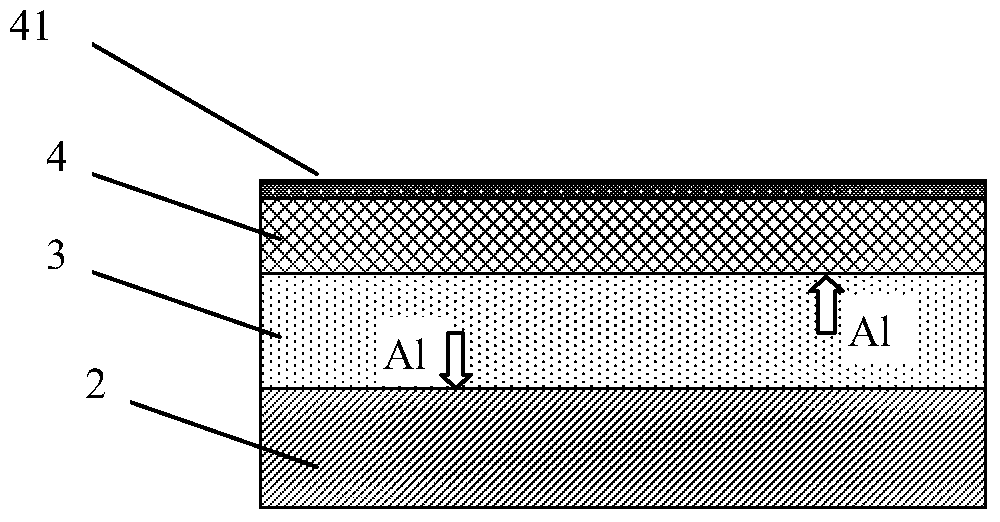

[0028] Such as figure 1 , 2 Shown is a gas turbine blade composite coating of the present invention, including MCrAlY layer 2, NiAl layer 3 and nanocrystalline layer 4 coated sequentially on the MGA1400 superalloy blade as a superalloy substrate 1. The thickness of the MCrAlY layer is 100-200 microns, and the MCrAlY layer is prepared by low-pressure plasma spraying or supersonic flame spraying on the surface of the superalloy substrate 1 . The thickness of the NiAl layer is 20-50 microns, the composition of the nano-crystal layer 4 is the same as that of the superalloy substrate 1, the nano-crystal layer 4 is prepare...

Embodiment 2

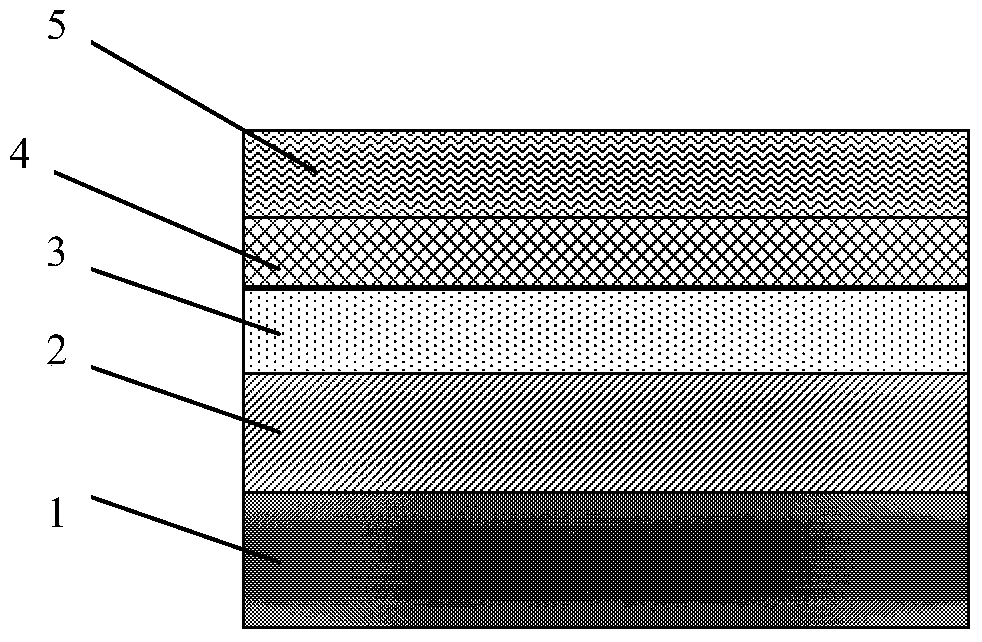

[0036] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that for the superalloy blades of the first two stages, in order to reduce the working temperature and protect the base metal material of the blade, it is also necessary to pass a plasma spraying process on the surface of the nanocrystalline layer 4 Preparation of ZrO 2 Based thermal barrier ceramic coating 5, that is, a composite coating composed of MCrAlY layer 2, NiAl layer 3 and nanocrystalline layer 4 as ZrO 2 The bonding layer of the thermal barrier coating ceramic layer 5, ZrO 2 The thickness of the base thermal barrier ceramic coating 5 is 100-300 microns, and the composite coating at this time is used to improve the bonding force of the thermal barrier coating and improve the high temperature oxidation resistance of the blade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com