A method for moving a cantilever beam out and back to a platform as a whole

A cantilever beam and cantilever beam type technology is applied in the field of moving the cantilever beam out and back to the platform as a whole. , Reduce the difficulty and danger of construction, and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

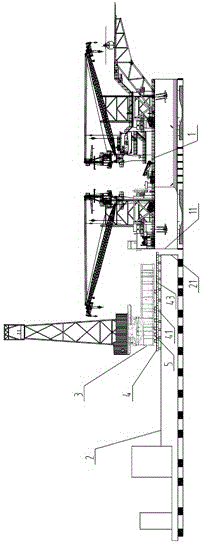

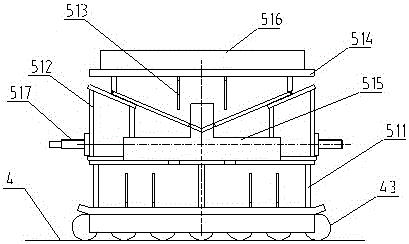

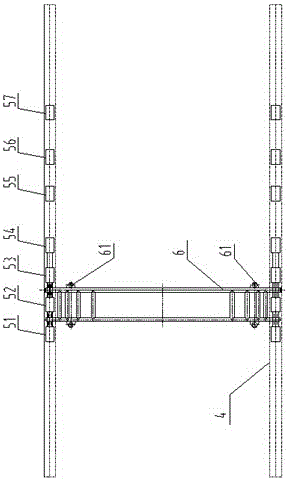

[0054] A method for the cantilever beam to move out and back to the platform as a whole, such as Figure 1 to Figure 7 shown. The method is operated in the dock, including the process of moving the cantilever beam 3 from the platform 1 of the cantilever drilling platform to the floating dock 2 as a whole, and after the cantilever beam 3 and the platform 1 are respectively refitted, the cantilever beam 3 The move back process from floating dock 2 to platform 1.

[0055] The steps in the removal process are:

[0056] A1. According to the structure of the cantilever beam drilling platform and the floating dock 2, the docking pier and the sand pier are respectively placed in the dock, and the cantilever beam drilling platform and the floating dock 2 are docked successively. The rear end plate 21 of the floating dock 2 is parallel to the stern seal plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com