Rotary-type prestressed tubular pile segmentation static load test method and device

A technology of prestressed pipe piles and test devices, which is applied in the direction of basic structure tests, buildings, and basic structure engineering, etc., can solve the problem of high cost of static load tests, and achieve the effect of saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

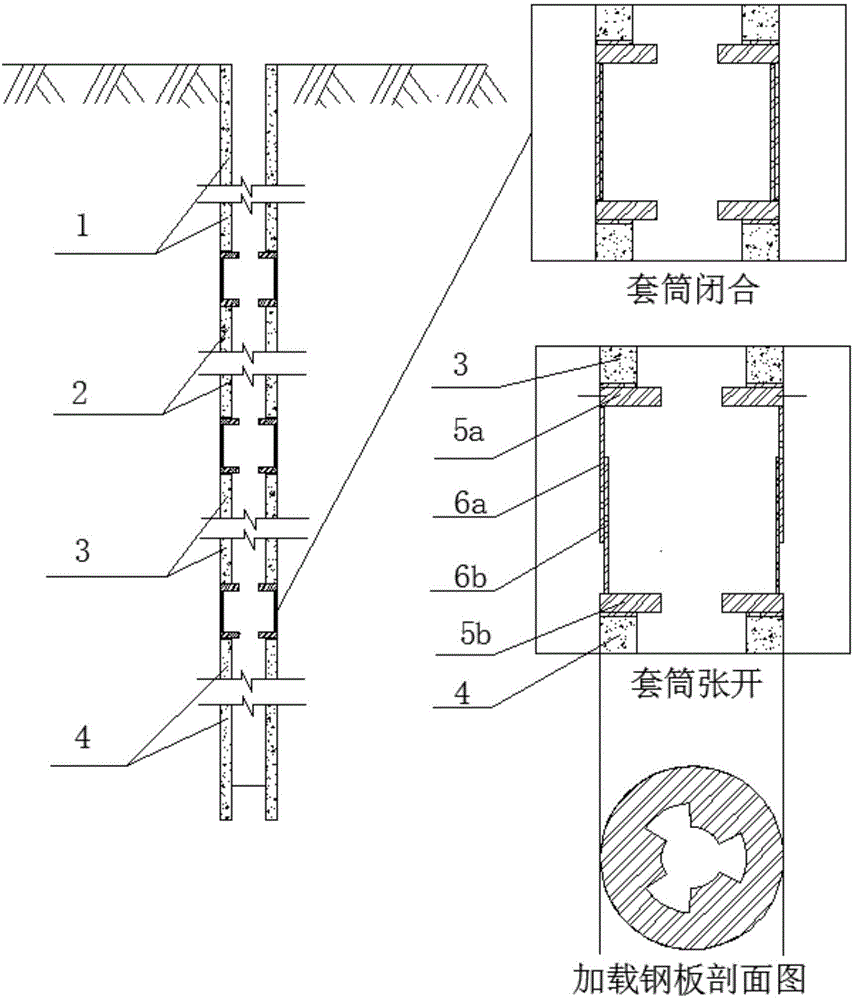

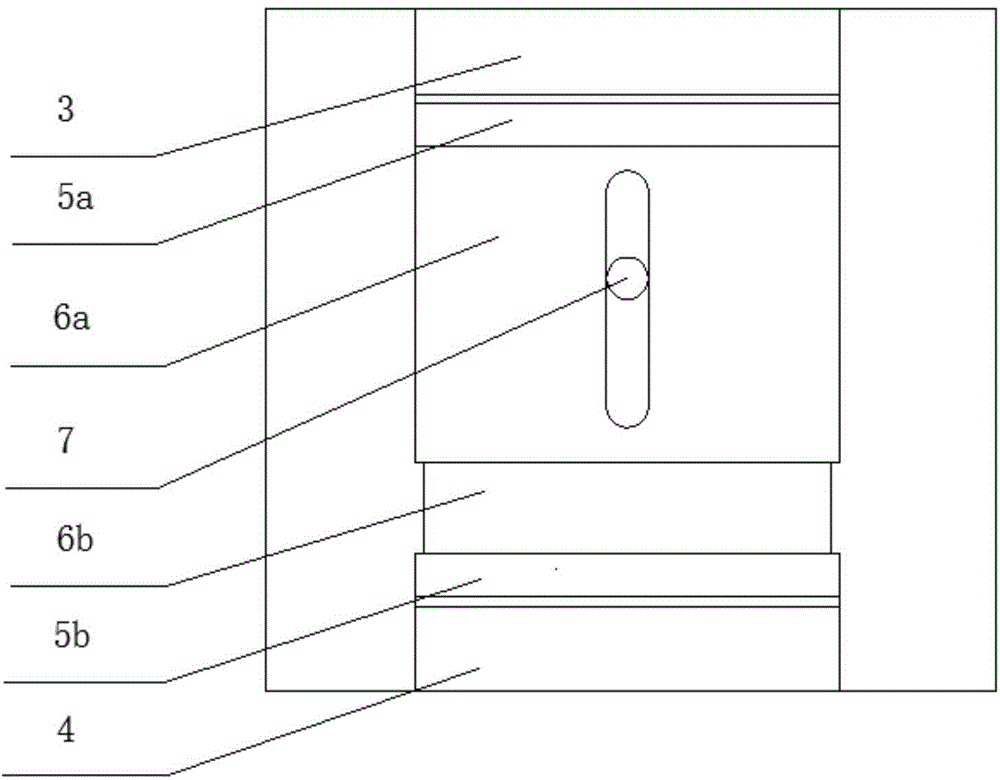

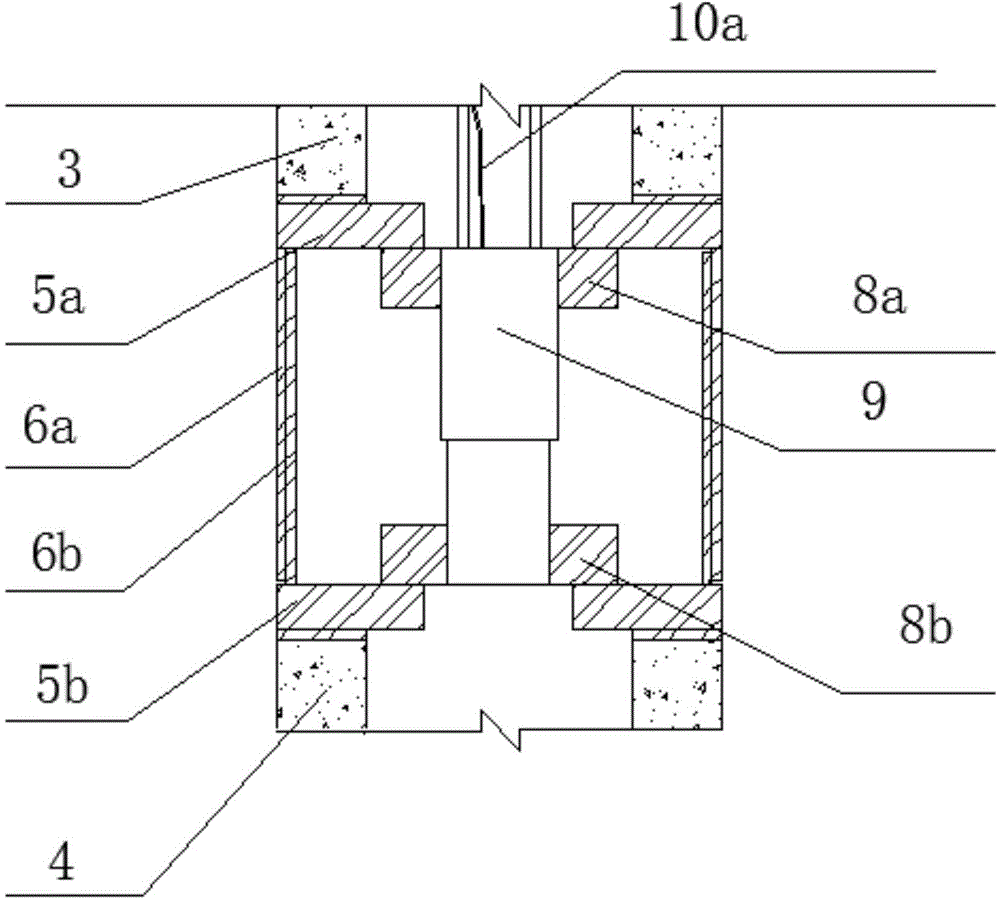

[0036] Such as figure 1 As shown, the prestressed pipe pile is divided into N sections. Taking four sections as an example, the prestressed pipe pile includes the first section of prestressed pipe pile 1, the second section of prestressed pipe pile 2, the third section of prestressed pipe pile 3 and Section 4 Prestressed pipe pile 4; the connection of prestressed pipe pile is as follows figure 1 As shown, each adjacent prestressed pipe pile is connected by a sleeve 6; the sleeve 6 includes an outer sleeve 6a and an inner sleeve 6b which are staggered, and the outer sleeve 6a is sleeved on the inner sleeve 6b. The radii of the outer sleeve 6a and the inner sleeve 6b are matched, and can cooperate and slide with each other; when the outer sleeve 6a and the inner sleeve 6b overlap, they can transmit force to each other;

[0037] Such as figure 1 , figure 2 As shown, the outer sleeve 6a is welded under the loaded steel plate 5a welded at the bottom of the prestressed pipe pile...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com