Thin porous brick masonry type pipeline-embedded heat insulation wall for single-surface wall

A technology for pre-embedding pipelines and thermal insulation walls, which is applied in the direction of walls, building materials, building components, etc., can solve the problems of unfavorable wall quality, increased engineering volume, weak bonding, etc. , better thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

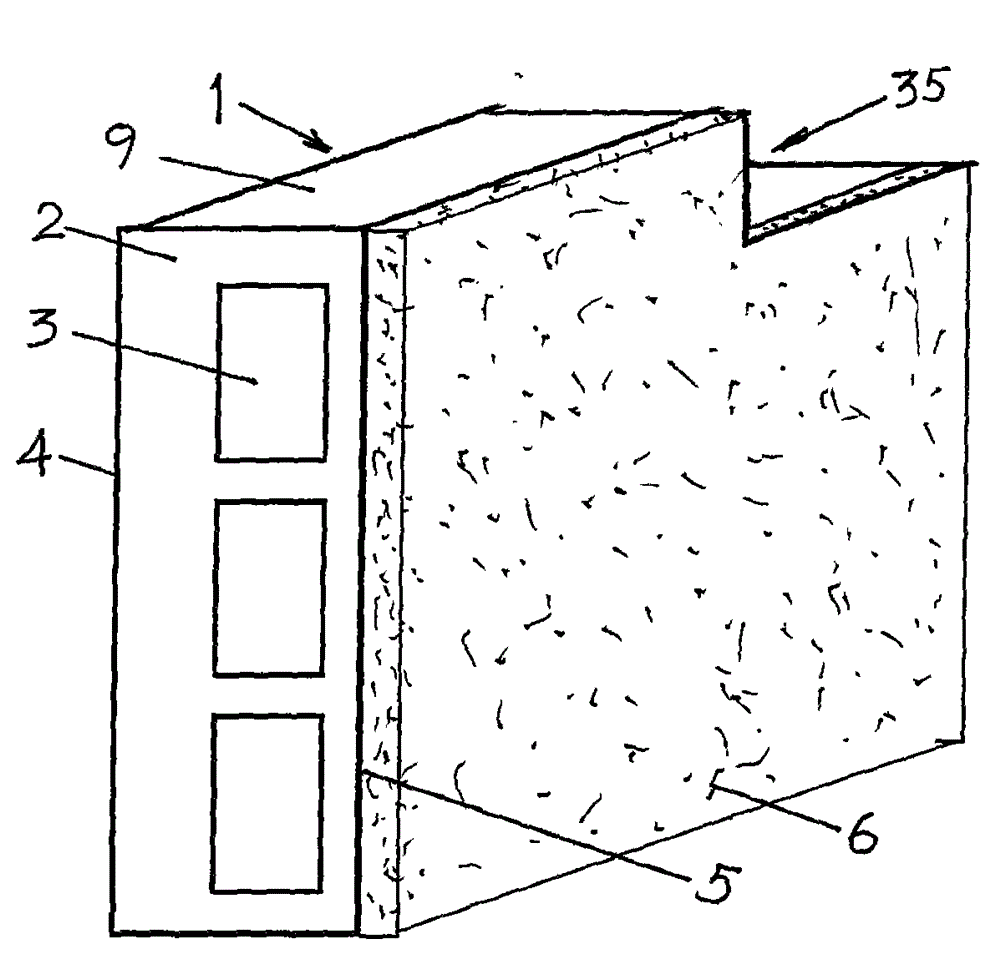

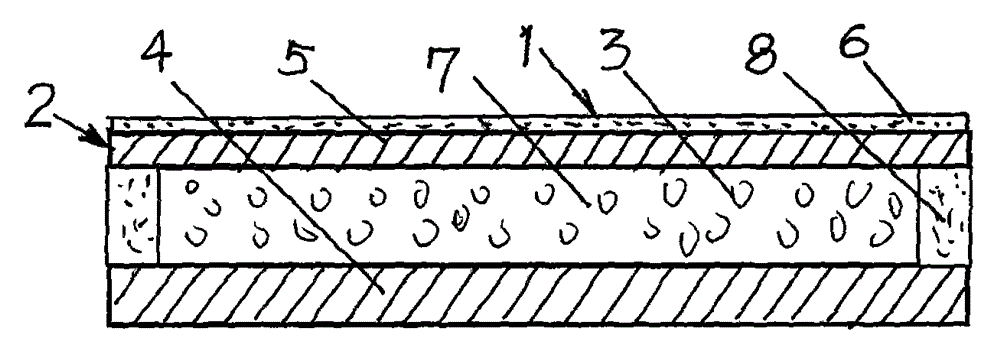

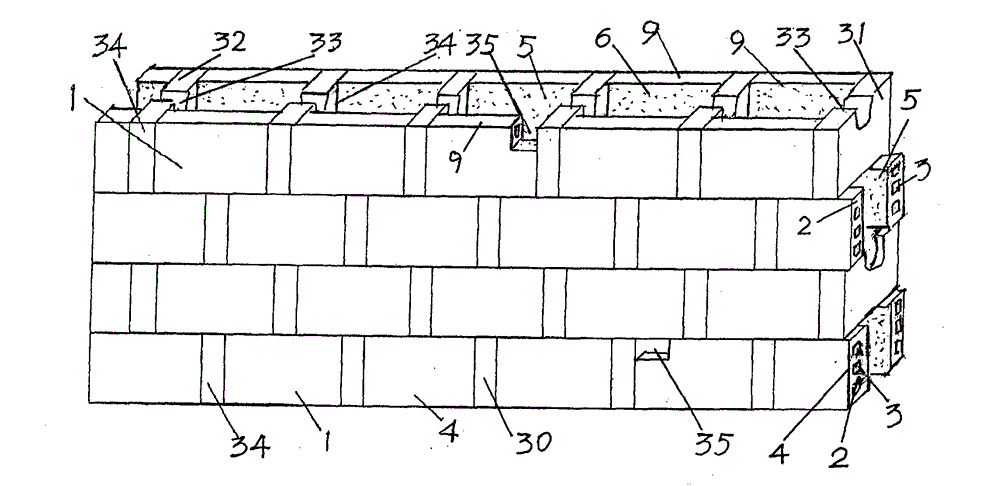

[0039] Embodiment 1, the pre-embedded pipeline insulation wall of thin porous bricks for single-sided walls

[0040] Such as figure 1 , 2 , 3, 4, comprising a plurality of flat bricks 34 with threading recesses and thin molded bricks 1 combined into a body of wall;

[0041] The structure of the flat brick 34 with threading recess is: comprise a rectangular parallelepiped molded flat brick 30, the molded flat brick 30 has two main faces 31 with the same area, and there are four elongated sides 32 around the main face 31. It is characterized in that: among the four elongated side faces 32, there is a recessed notch 33 in the middle of one side 32, and the recessed notch 33 makes the corresponding edge positions of the two main surfaces 31 also have a recessed shape; the opening width of the recessed notch 33 2-6 centimeters, the depth of the recessed gap 33 is 2-6 centimeters.

[0042] The structure of the thin molded brick 1 is as follows: the outer dimension of the thin mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com