Energy theory-based prediction method for stress of TMB (tunnel boring machine) disk hob

A disc-shaped hob and prediction method technology, which is applied in the fields of earth drilling, electrical digital data processing, and special data processing applications, and can solve problems such as model development lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Below in conjunction with accompanying drawing and research the present invention is described in further detail.

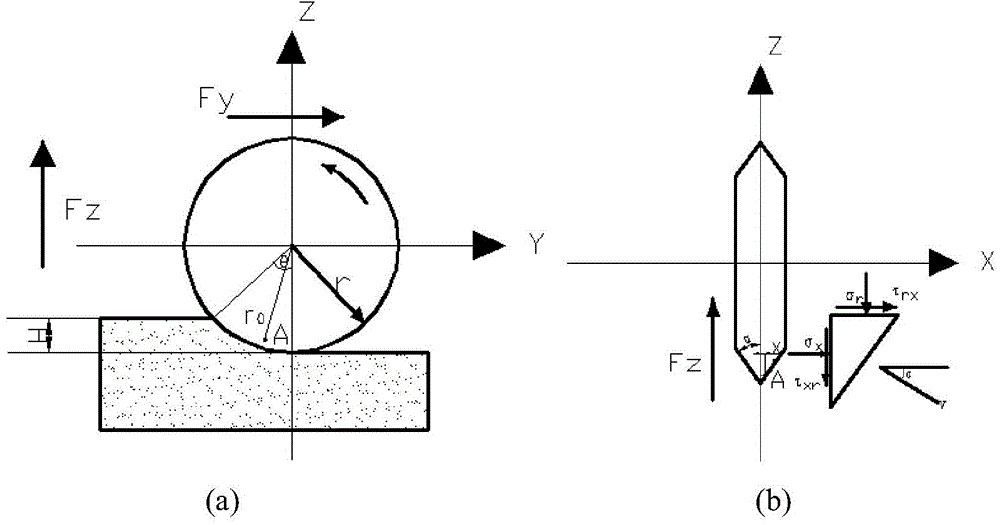

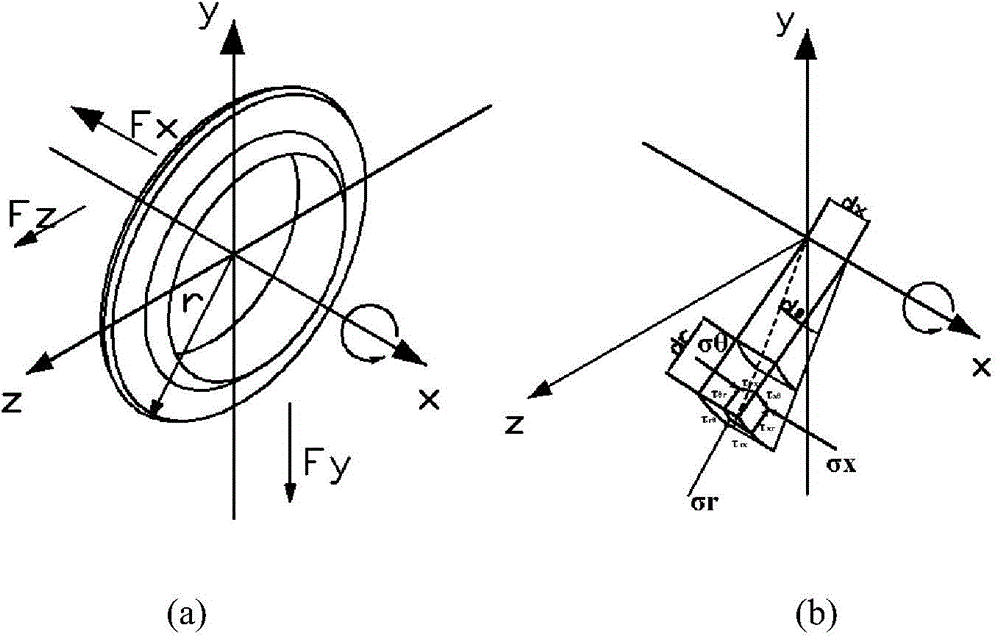

[0074] The force prediction method of the TBM disc-shaped hob based on the energy principle of the present invention is mainly through comparative analysis with other two classic prediction models. The analysis of the force and energy characteristics is also consistent with the conclusion obtained by using the finite element simulation software that "as the rotation speed of the cutter head increases, the three-dimensional force also increases." And using the experimental data and model calculation data recorded in the C. Balci literature, compared with the calculation data of the model proposed by this method, it can be seen that with the increase of rock strength and tool penetration, the calculation results of this method are closer to on the experimental data.

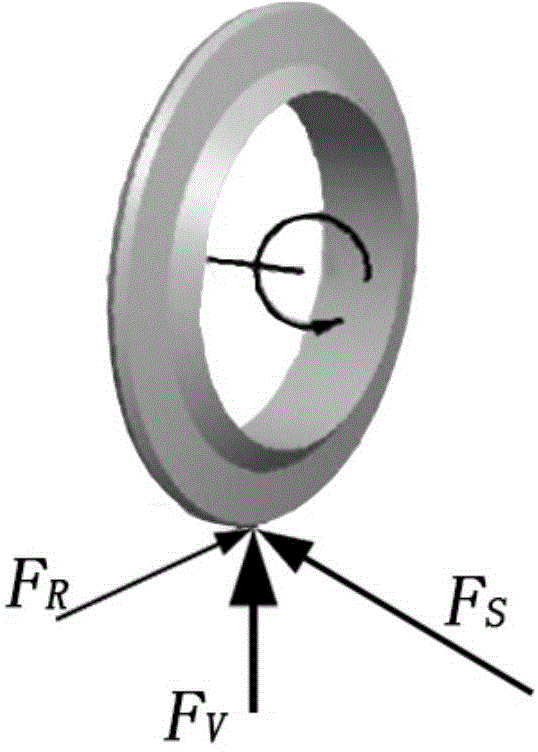

[0075] The method for predicting the force of the TBM disc hob comprises the following ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com