Hall-sensing electronic accelerator assembly based on AMT (Automated Mechanical Transmission)

A technology of electronic throttle and hall sensing, applied in engine control, machine/engine, mechanical equipment, etc., can solve the problems of uncompact structure and poor positioning, and achieve the effect of compact structure, long service life and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

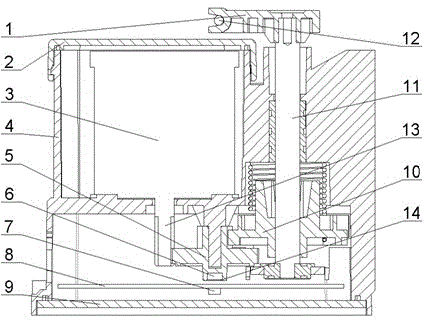

[0015] Such as figure 1 As shown, an AMT-based Hall sensor electronic throttle assembly includes a control mechanism, an actuator and a position feedback mechanism. The actuator includes a housing 4, a housing cover 2, and a wire reel 1. The control mechanism includes a motor 3 , the control unit 8, the position feedback mechanism includes a magnet 6 and a Hall element 7; the above-mentioned housing cover 2 is connected to the housing 4, and a gear reduction device 10, a DC brushless motor 3, a bearing, and an angle sensor are installed in the housing 4; The above-mentioned gear reduction device 10 is a two-stage reduction gear, and the two-stage reduction gear includes a gear shaft and a gear set respectively, and transmits torque through gear engagement; At the shaft end of the gear reduction output shaft 11 of the gear reduction device 10; the steel wire reel 1 is decelerated and driven by the gear reduction device 10, and the gear reduction device 10 drives the steel wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com