A flameless incineration process for solid waste

A solid waste and process technology, applied in the direction of gas production bioreactors, incinerators, combustion methods, etc., can solve problems such as complex operation, easy flameout, and serious pollution, and achieve high processing efficiency, high carbon content, and application wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: a kind of flameless incineration process of solid waste, it comprises the following steps:

[0033] S1. Sorting treatment: use a combination of manual sorting, mechanical sorting and instrument detection to sort out plastics, rubber and heavy metals from solid waste;

[0034] S2. Anaerobic fermentation: move the sorted solid waste to the anaerobic fermentation chamber for fermentation treatment, so that the water content of the solid waste is reduced by 5%. The height of the solid waste stacked in the anaerobic fermentation chamber is 5m, the time of fermentation treatment is 5 days;

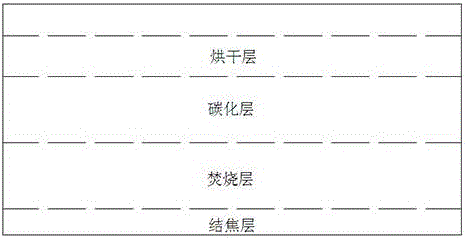

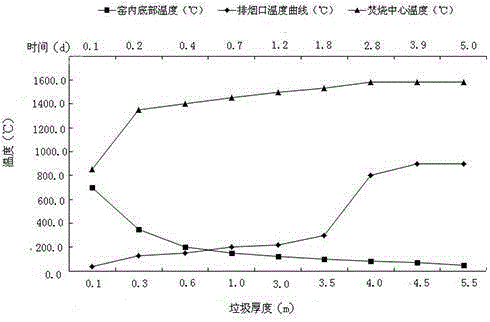

[0035]S3. Flameless incineration: the solid waste after anaerobic fermentation is piled up in the incineration kiln for 5m, and the bottom of the incineration kiln is equipped with an ignition system and a gas supply system, and the auxiliary gas is fed into the gas supply system at a flow rate of 10m / s , ignite through the ignition system, and then incinerate into the desi...

Embodiment 2

[0041] Embodiment 2: a kind of flameless incineration process of solid waste, it comprises the following steps:

[0042] S1. Sorting treatment: use a combination of manual sorting, mechanical sorting and instrument detection sorting to sort out plastics, rubber and heavy metals from solid waste;

[0043] S2. Anaerobic fermentation: move the sorted solid waste to the anaerobic fermentation chamber for fermentation treatment, so that the water content of the solid waste is reduced by 15%. The height of the solid waste stacked in the anaerobic fermentation chamber is 7m, the time of fermentation treatment is 10 days;

[0044] S3. Flameless incineration: the solid waste after anaerobic fermentation is piled up in the incineration kiln for 7m, and the bottom of the incineration kiln is equipped with an ignition system and a gas supply system, and the auxiliary gas is fed into the gas supply system at a flow rate of 50m / s , ignite through the ignition system, and then incinerate in...

Embodiment 3

[0050] Embodiment 3: a kind of flameless incineration process of solid waste, it comprises the following steps:

[0051] S1. Sorting treatment: use a combination of manual sorting, mechanical sorting and instrument detection to sort out plastics, rubber and heavy metals from solid waste;

[0052] S2. Anaerobic fermentation: move the sorted solid waste to an anaerobic fermentation chamber for fermentation treatment, so that the water content of the solid waste is reduced by 8%. The height of the solid waste stacked in the anaerobic fermentation chamber is 5.8m, the time of fermentation treatment is 7 days;

[0053] S3. Flameless incineration: The solid waste after anaerobic fermentation is piled up in the incineration kiln for 5.8m. The bottom of the incineration kiln is equipped with an ignition system and a gas supply system, and the auxiliary gas is fed into the gas supply system at a flow rate of 25m / s. The gas is ignited through the ignition system, and then incinerated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com