An upper submerged heating, melting and holding furnace

A holding furnace and immersion technology, applied in lighting and heating equipment, furnaces, crucible furnaces, etc., can solve the problems of leakage of protective casing, time and energy consumption, and inconvenient operation, so as to avoid direct impact and direct burn The effect of burning and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

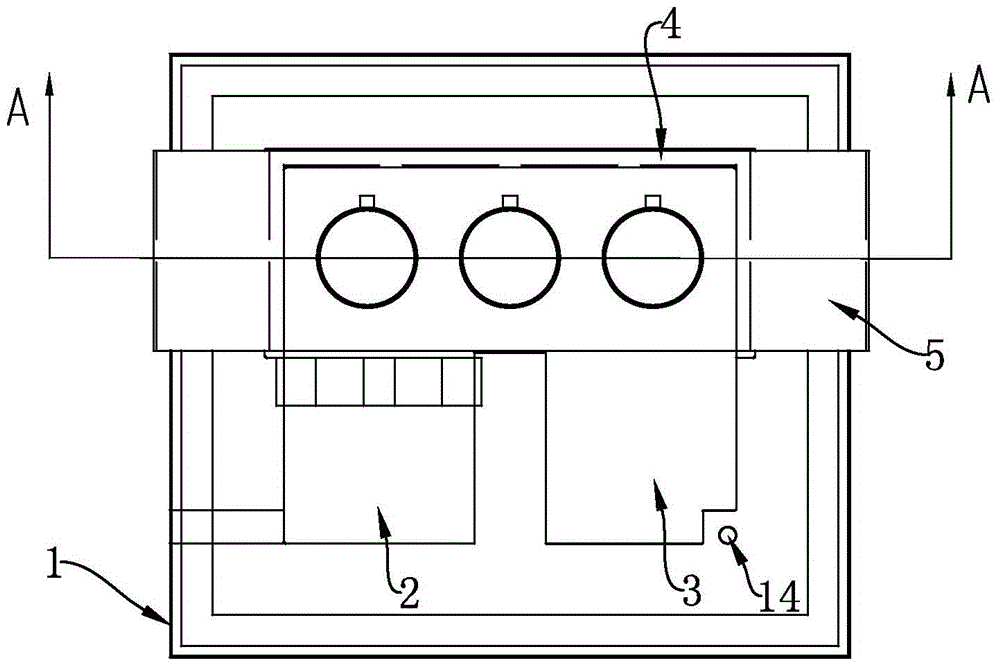

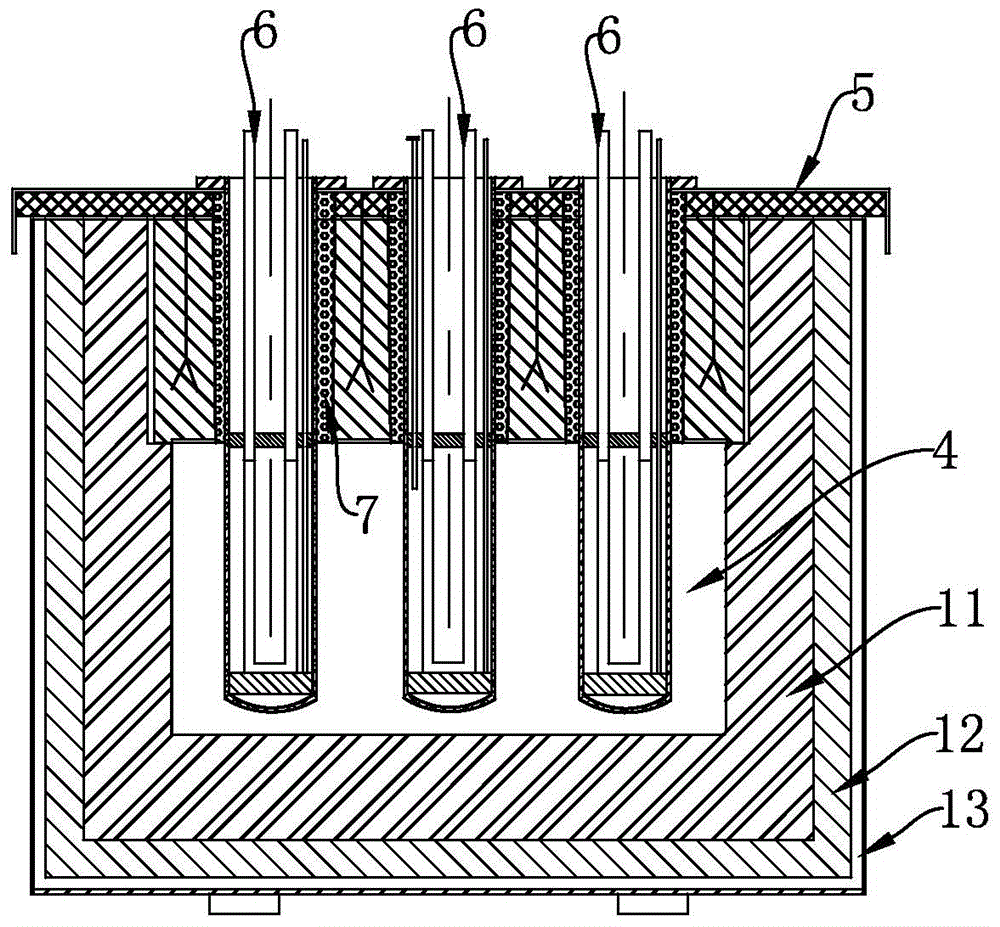

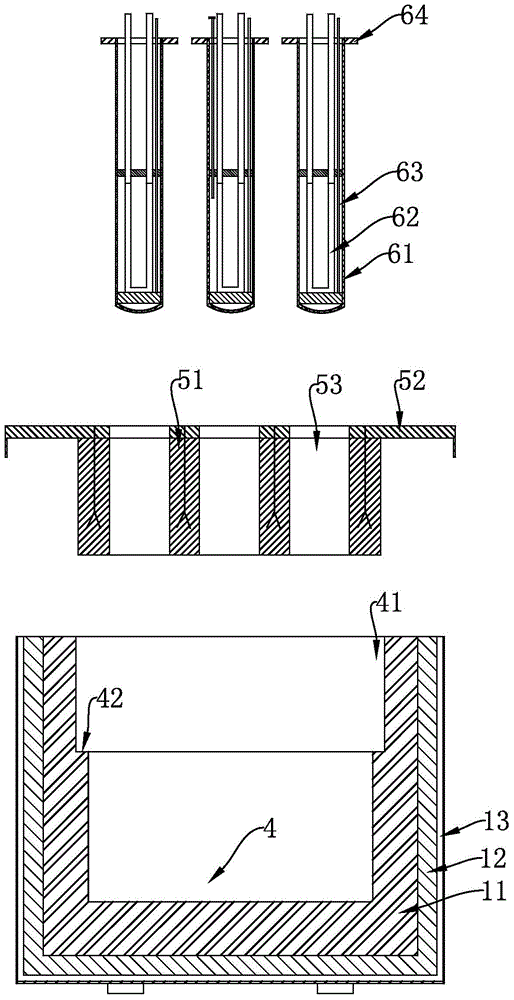

[0025] Such as Figure 1~3 As shown, an upper immersion heating, melting and holding furnace of the present invention includes: a furnace body 1, a furnace cover 5, a heater 6, and an electric control cabinet.

[0026] The furnace wall of the furnace body 1 includes a three-layer structure, wherein the inner layer structure 11 is an integrally cast refractory material, the middle layer structure 12 is an insulating brick, and the outer layer structure 13 is a fiberboard. Such a three-layer structure design not only improves the furnace body 1. Corrosion resistance also reduces heat loss. The inner cavity of the furnace includes three chambers: feeding area 2, discharging area 3, and heating area 4, among which:

[0027] ——The feeding zone 2 and the discharging zone 3 are completely separated by a sealing baffle, the purpose is to prevent the temperature drop of the molten metal in the discharging zone due to the mixing of the newly added material with the molten metal in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com