A phase-enhanced thin film thickness measurement method and system

A film thickness enhancement technology, applied in the field of phase enhancement film thickness measurement, can solve the problems of limited precision, high frequency film roughness, unsatisfactory film step preparation, large error rate, etc., and achieve the effect of reducing the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

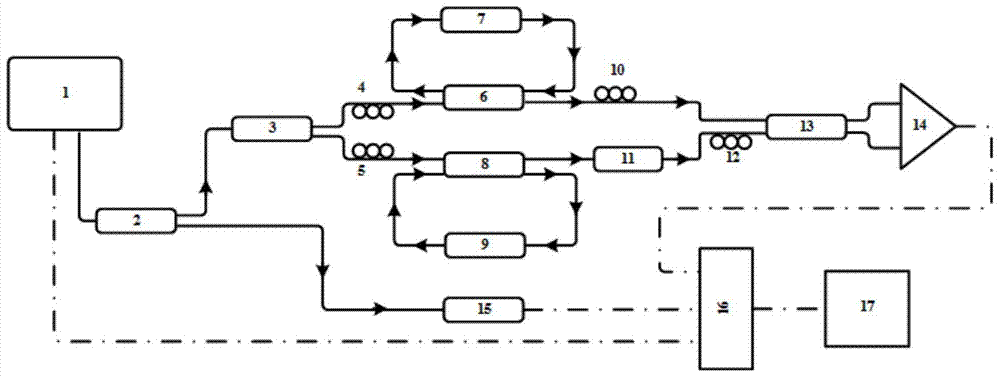

[0041] Such as figure 1 As shown, the present invention includes a broadband sweeping light source 1, a first broadband fiber coupler 2, a second broadband fiber coupler 3, a first polarization controller 4, a second polarization controller 5, a third broadband fiber coupler 6, Measurement sub-cycle cavity 7, fourth broadband fiber coupler 8, reference sub-cycle cavity 9, third polarization controller 10, fiber delay line 11, fourth polarization controller 12, fifth broadband fiber coupler 13, first high A bandwidth-balanced photodetector 14 , a sampling wavenumber drift correction unit 15 , a high-speed data acquisition card 16 , and a computer 17 .

[0042] The broadband sweeping light source 1 is connected to the input end of the second broadband fiber coupler 3 and the input end of the sampling wave number drift correction unit 15 respectively throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com