Non-contact stress detection system and method

A stress detection, non-contact technology, applied in the direction of force measurement, material magnetic variables, etc. by measuring the change of magnetic properties of materials caused by applied stress, which can solve the problem of reducing the rigidity of components and dimensional stability of components, and the power consumption of detection devices. The problems cannot be ignored, the equipment working environment is bad, etc., to achieve the effect of low power consumption, low cost and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and embodiments.

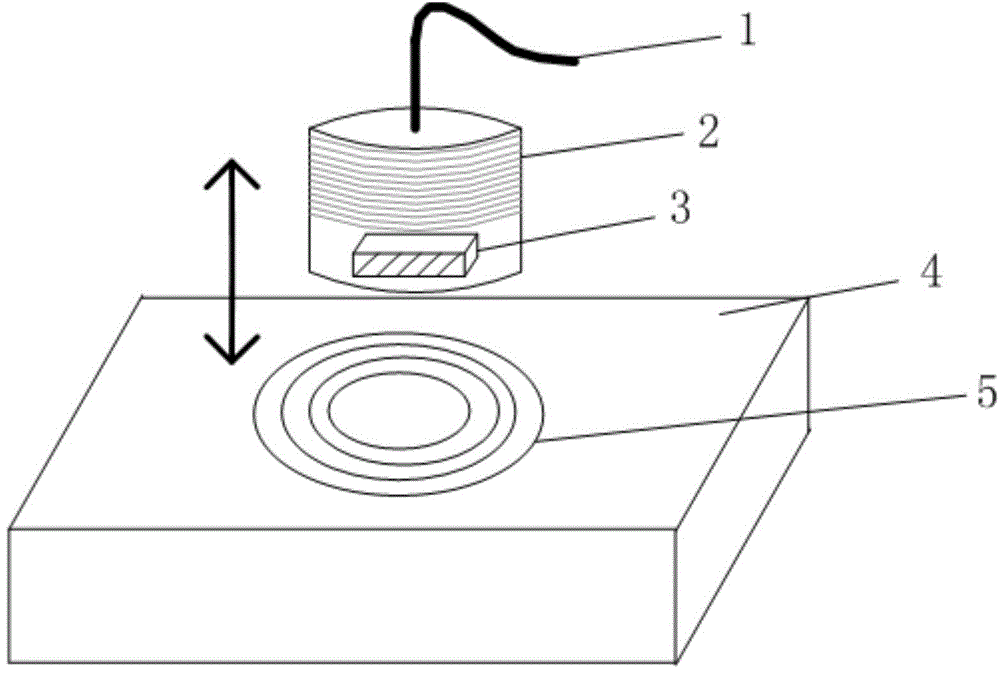

[0024] Such as figure 1 As shown, a non-contact stress detection method is used to detect the rail stress through the magnetic field intensity measured by the giant magnetoresistive element.

[0025] Further, the giant magnetoresistive element is a GMR sensor, which can measure both dynamic magnetic field strength and static magnetic field strength. After the data is measured by the GMR sensor, it is uploaded to the upper computer for data analysis and processing.

[0026] Further, the magnitude of the magnetic field strength is the superposition of the magnetic field strength generated by the excitation coil and the magnetic field strength generated by the rail eddy current effect.

[0027] Further, the magnetic field generated by the excitation coil is generated by an alternating current of a fixed frequency applied to the excitation coil, and the magnitude and direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com