Automatic separation equipment of crude oil components and its application in the separation of wax and gum in crude oil

An automatic separation and equipment technology, applied in the field of chemical separation, can solve the problems of restricting the evaluation efficiency of crude oil properties, affecting the accuracy of results, poor data repeatability, etc., to shorten the injection time, save the cleaning time, and reduce the damage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

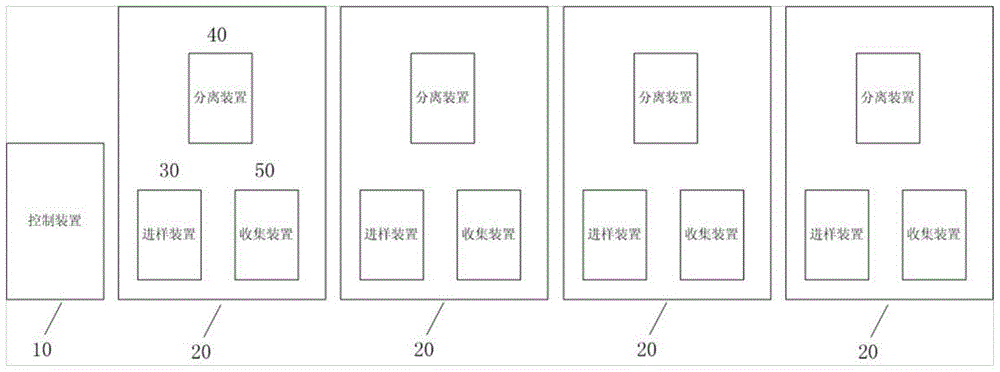

[0045] Refer to attached figure 1The crude oil component automatic separation equipment of the present invention comprises: a control device 10 and at least one separation module 20 (there are 4 separation modules in the figure), wherein the number of separation modules 20 can be adjusted according to actual needs, specifically 1, 2, 3, 4 or 5 pieces. The separation module 20 includes a sampling device 30 , a separation device 40 , and a collection device 50 . The control device 10 is connected to the sampling device 30 , the separation device 40 , and the collection device 50 in communication.

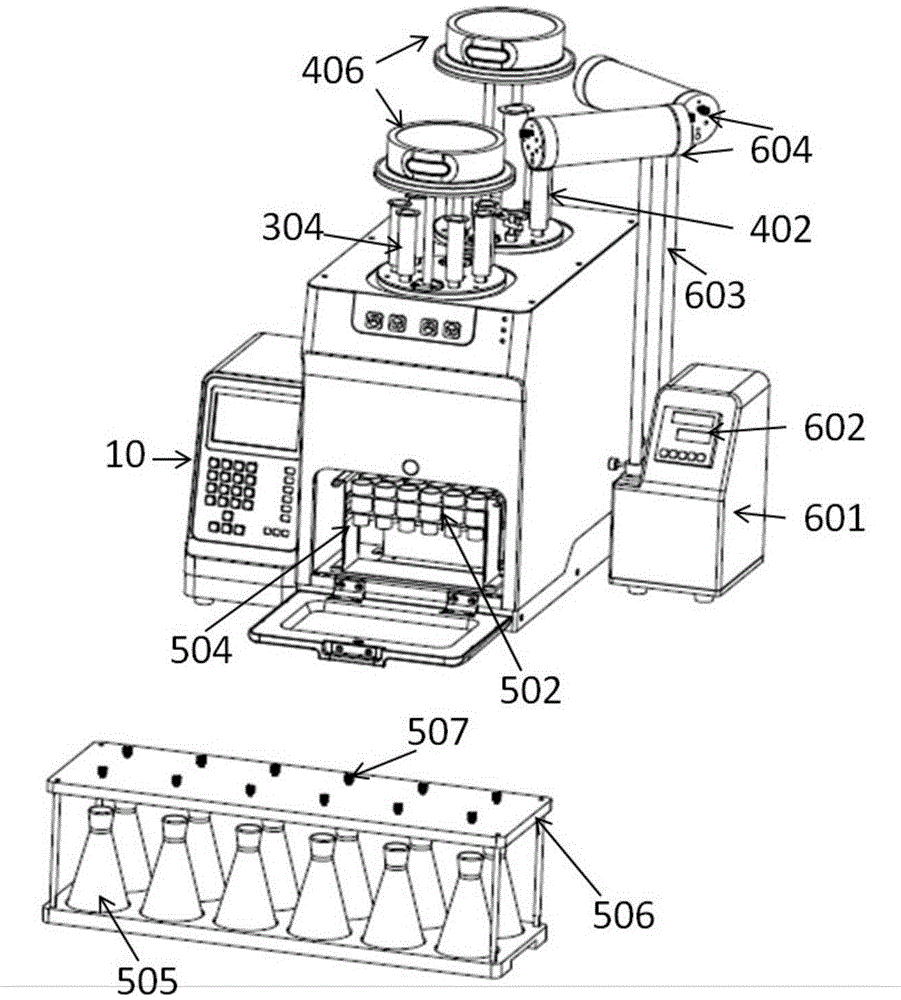

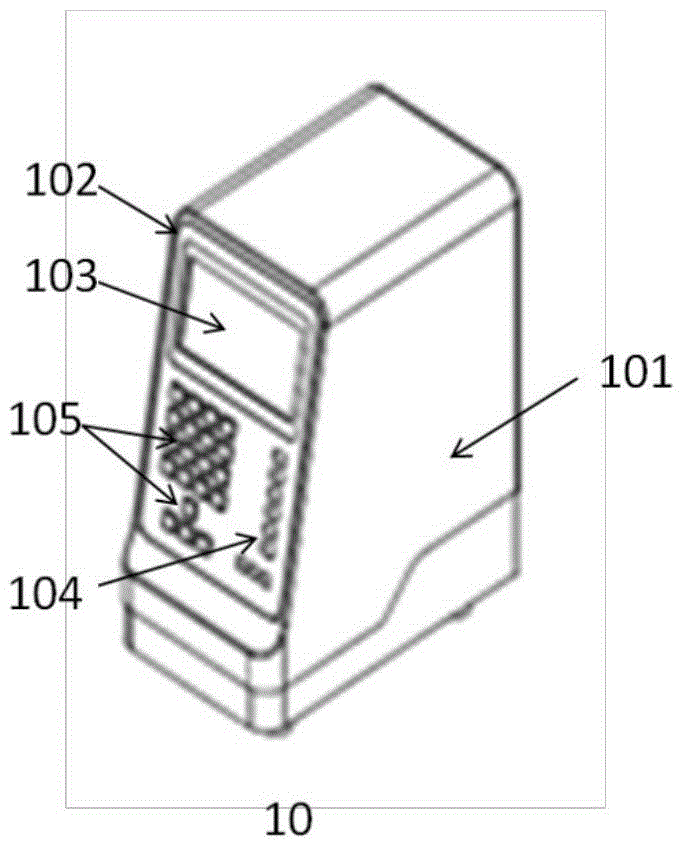

[0046] The control device 10 can be an industrial computer. In a specific embodiment, refer to the attached figure 2 And attached image 3 , the control device 10 includes a control box main body 101, a control panel 102 installed outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com