Optical grating, display device and manufacturing method of optical grating

A manufacturing method and grating technology, applied in chemical instruments and methods, optics, optical components, etc., can solve the problems of light transmittance loss, module thickness, and affecting display effects, etc., and achieve the goal of reducing thickness and light transmission loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

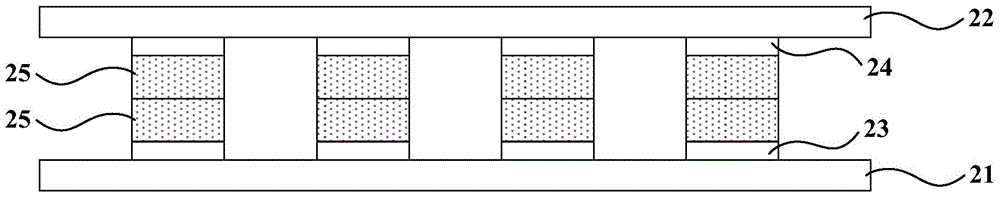

[0110] The manufacturing steps of the 3D liquid crystal display device are as follows:

[0111] Step 1, using a conventional method to manufacture a liquid crystal display panel;

[0112] Step 2. Form a first transparent electrode with a grating structure on the base substrate on the light-emitting side of the liquid crystal display panel. Specifically, an etching process can be used, for example, firstly fabricate an electrode layer covering the substrate surface of the base substrate, and then etch away Part of the electrode layer, forming a first transparent electrode with a grating structure;

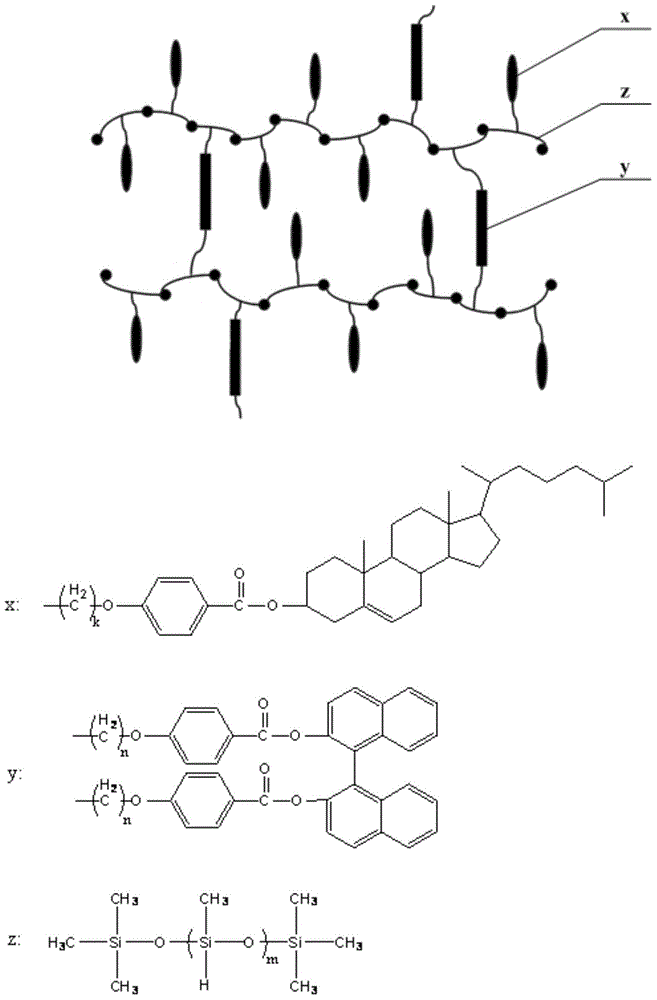

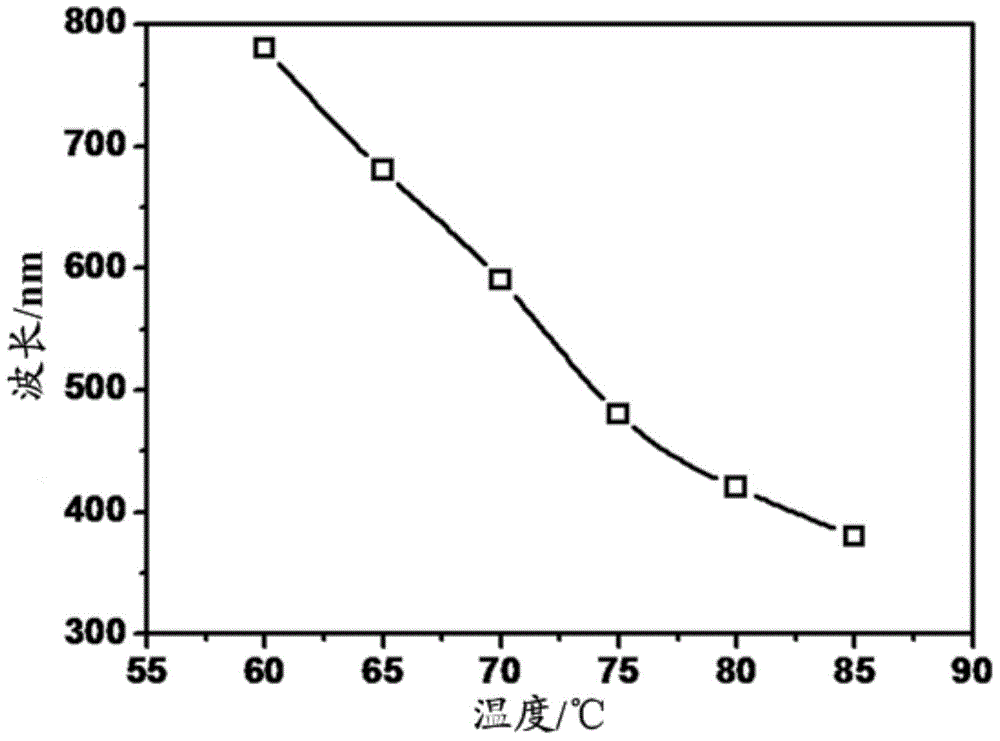

[0113] Step three, will figure 2 As shown n=4 and k=4, the binaphthyldiol crosslinking agent b and the liquid crystalline monomer a are grafted onto the polymethylhydrogensiloxane c of m=6 in a weight ratio of 5:4 to form silicon Oxane side chain liquid crystal elastomer, the obtained siloxane side chain liquid crystal elastomer, ferric oxide nanoparticles, ultraviolet light poly...

Embodiment 2

[0119] The manufacturing steps of the 3D liquid crystal display device are as follows:

[0120] Step 1, using a conventional method to manufacture a liquid crystal display panel;

[0121] Step 2. Form the first layer of transparent electrodes with a grating structure on the light-emitting side substrate of the display panel. Specifically, an etching process can be used. For example, firstly make an electrode layer covering the substrate surface of the substrate, and then etch away part of the electrode layer. an electrode layer, forming a first transparent electrode with a grating structure;

[0122] Step three, will figure 2 As shown n=6 and k=6, the binaphthyldiol crosslinking agent b and the liquid crystalline monomer a are grafted onto the polymethylhydrogensiloxane c of m=4 in a weight ratio of 3:2 to form silicon Oxane side chain liquid crystal elastomer, the obtained siloxane side chain liquid crystal elastomer, ferric oxide nanoparticles, ultraviolet light polymeriz...

Embodiment 3

[0128] The manufacturing steps of the 3D liquid crystal display device are as follows:

[0129] Step 1, using a conventional method to manufacture a liquid crystal display panel;

[0130] Step 2. Form the first layer of transparent electrodes with a grating structure on the light-emitting side substrate of the display panel. Specifically, an etching process can be used. For example, firstly make an electrode layer covering the substrate surface of the substrate, and then etch away part of the electrode layer. an electrode layer, forming a first transparent electrode with a grating structure;

[0131] Step three, will figure 2 As shown n=8 and k=8, the binaphthyldiol crosslinking agent b and the liquid crystalline monomer a are grafted onto the polymethylhydrogensiloxane c with m=10 in a weight ratio of 1:1 to form silicon Oxane side chain liquid crystal elastomer, the obtained siloxane side chain liquid crystal elastomer, ferric oxide nanoparticles, ultraviolet light polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com