High-flatness rigid-flex board provided with ink windows shaped like dual nested rectangles and manufacturing method

A technology of soft and hard combination board and manufacturing method, which is applied in the direction of printed circuit manufacturing, structural connection of printed circuit, printed circuit, etc. It can solve problems such as inconsistent shrinkage force, large deformation of board surface, and influence on flatness, so as to reduce ink area , high flatness, and the effect of reducing warpage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

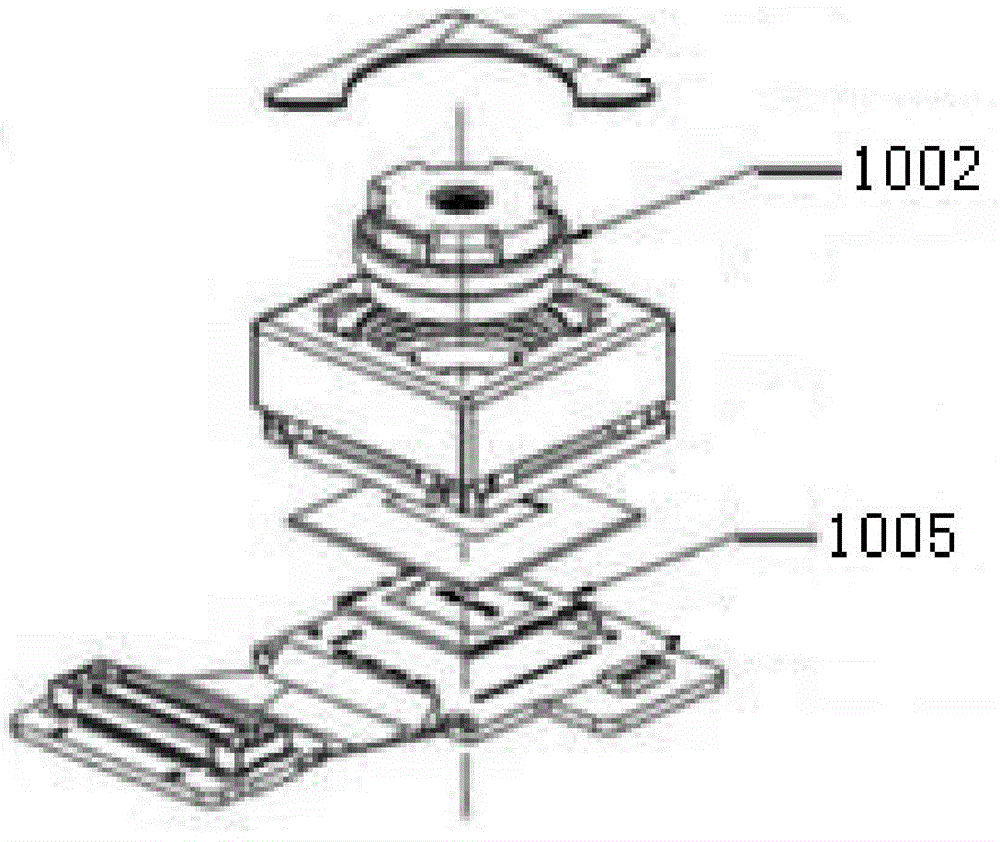

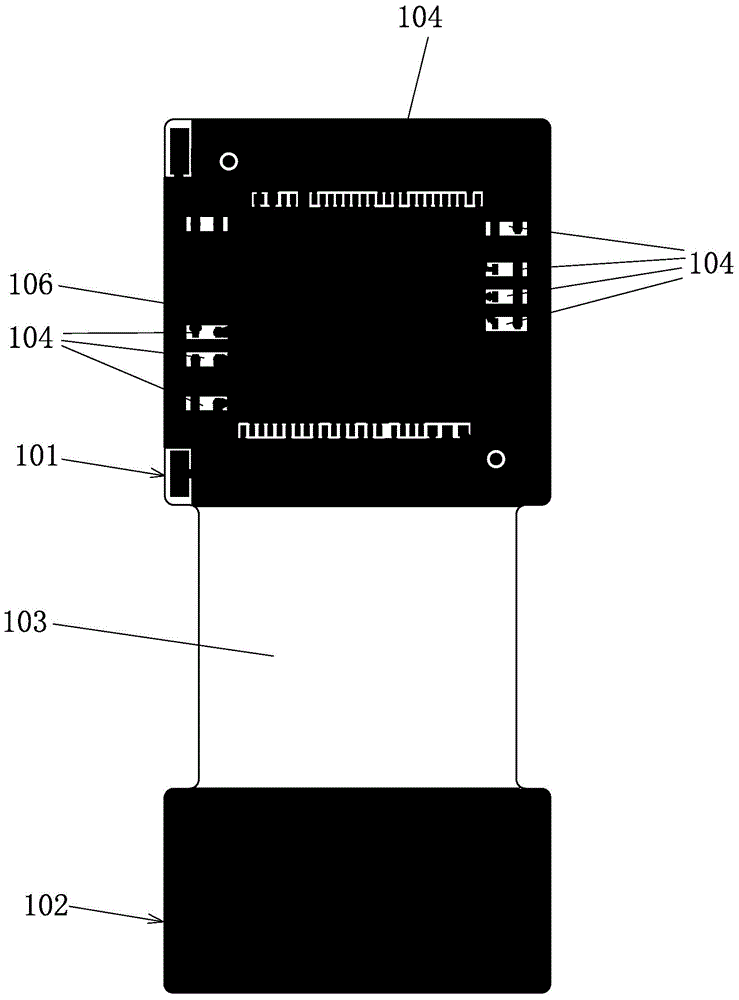

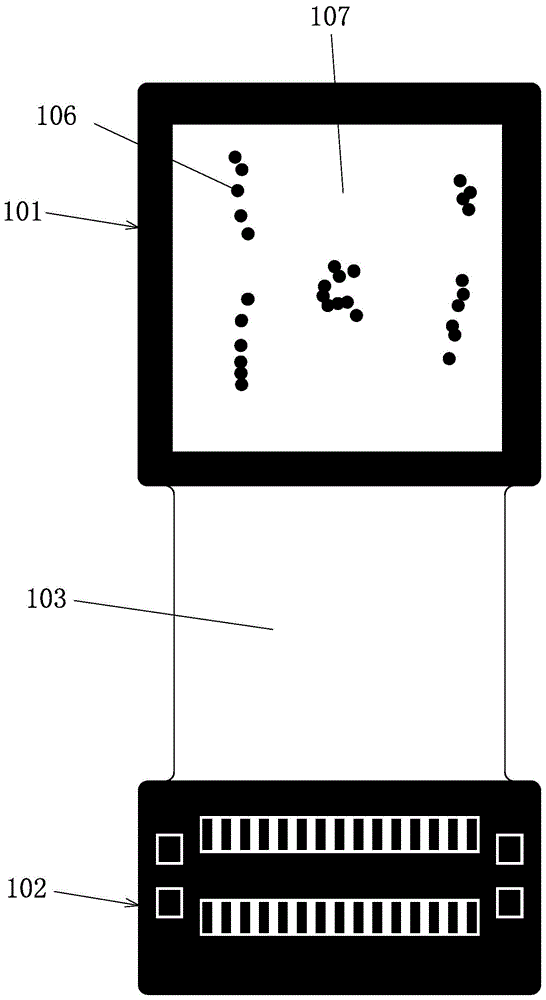

[0022] Such as Figure 4 and Figure 5 As shown, the flexible and rigid board with high flatness back-type ink window of the present invention includes rigid circuit boards 101, 102 and flexible circuit board 103, and the chip area of the rigid circuit board 101 is silk-screened with solder resist ink 109. The other side of the circuit board 101 opposite to the chip area is also provided with a gold surface 107 for heat dissipation. Only a few via holes on the surface of the gold surface 107 are covered with solder resist ink. Open the window 108 in the shape of back.

[0023] In order to form the back-shaped window 108, the present invention provides a method for manufacturing a high-flatness back-shaped ink window-opening flex-hard board, which includes the following steps: Step 1, rigid circuit boards 101, 102 and flexible circuit board 103 are bonded After the junction is solidified, through drilling, copper plating, circuit making and other processes, the outer circui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com