Tool for machining workpieces

A technology of cutting processing and cutting parts, which is applied in the field of cutting tools and can solve problems such as time-consuming and complicated adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

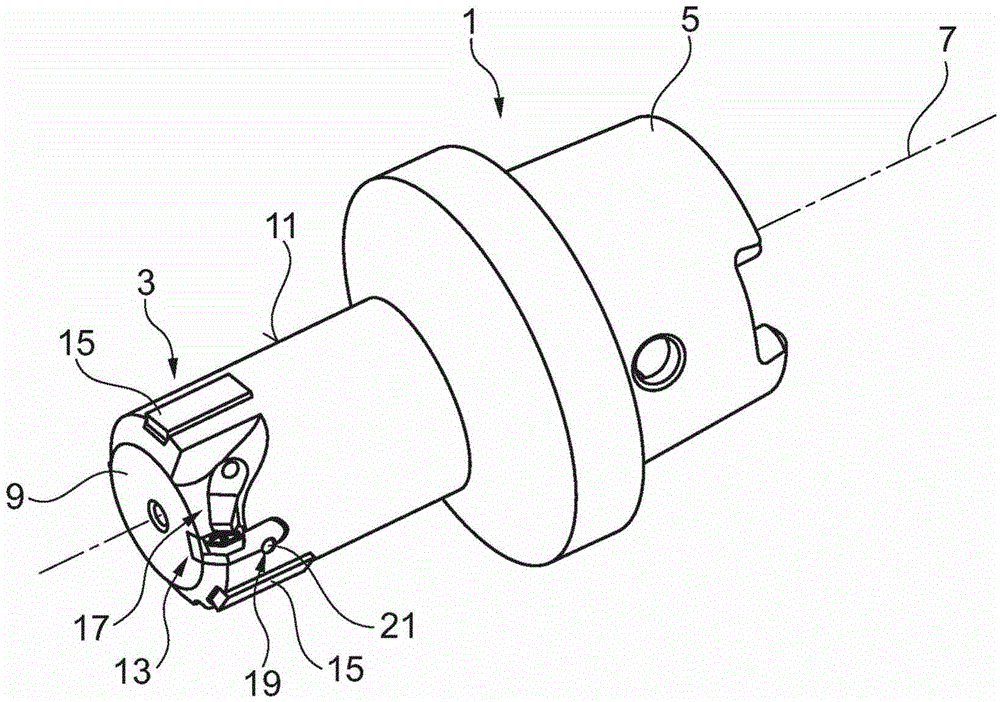

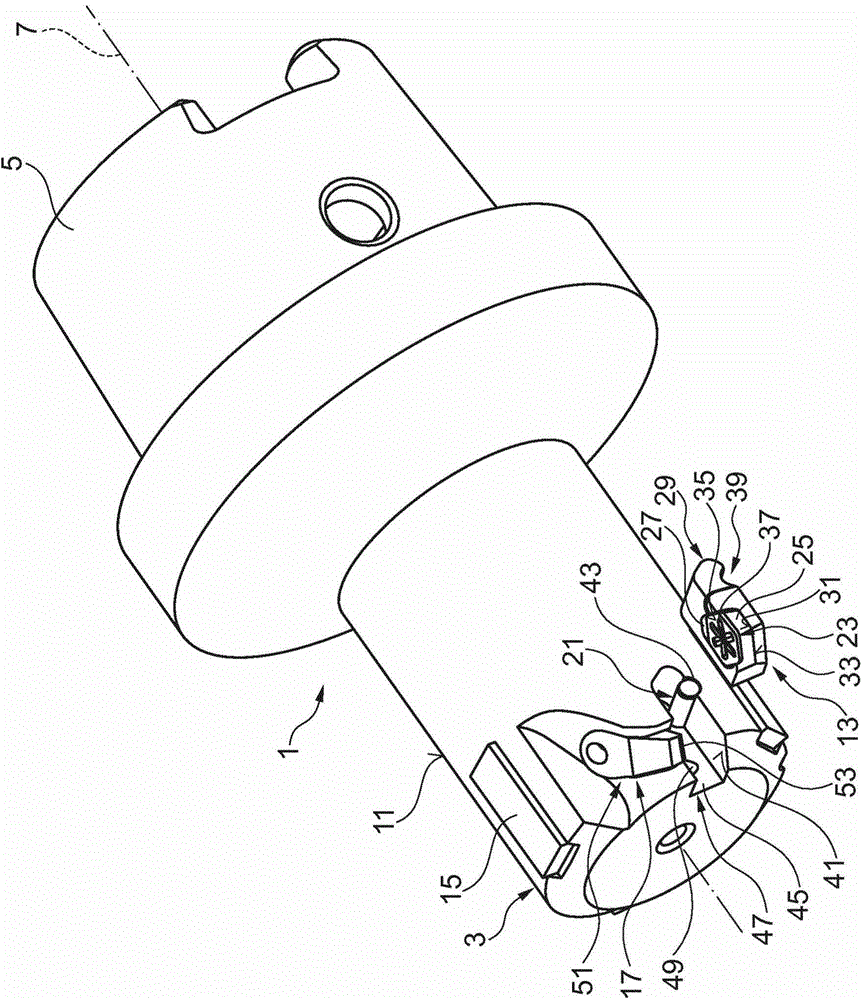

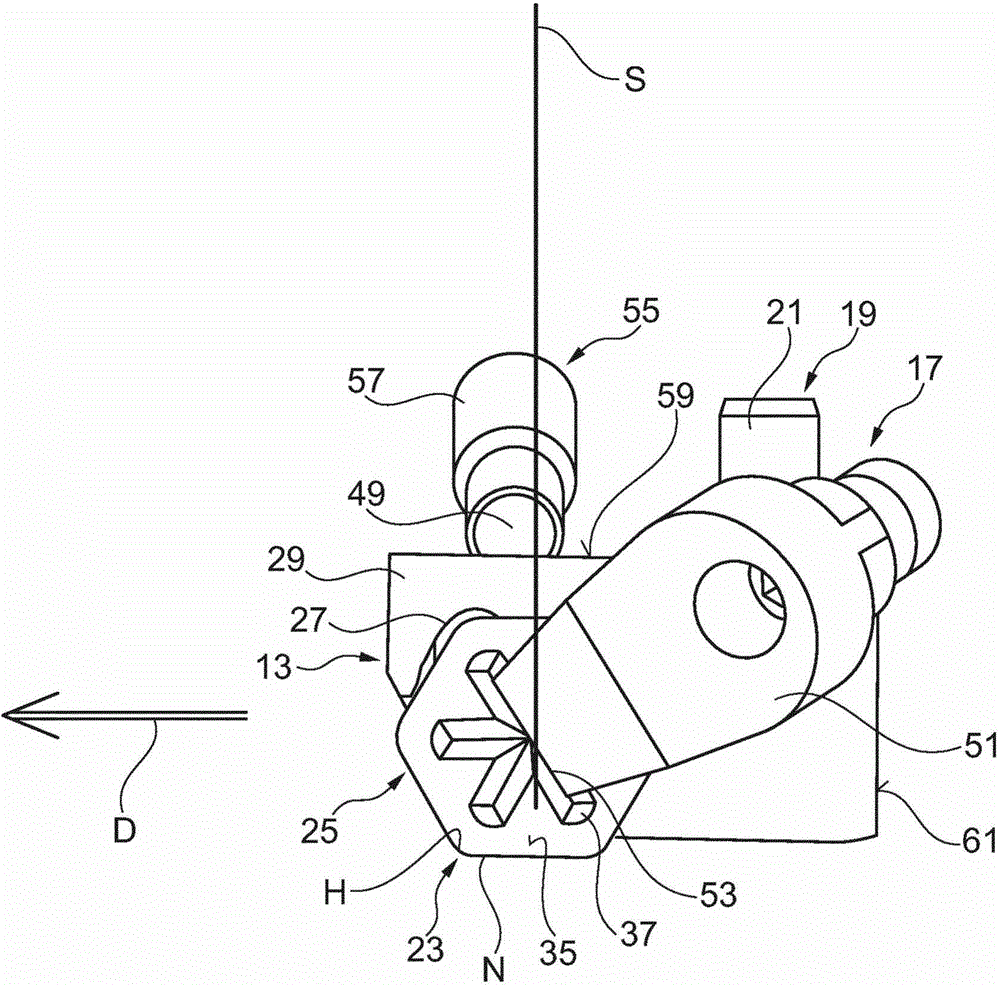

[0021] figure 1 A tool 1 is depicted, in particular a precision drilling tool, preferably a reamer. The tool 1 has a tool head 3 and a tool shank 5 , which here is designed in the form of a hollow rod and serves to fasten the tool 1 in a machine tool, a joint or an intermediate part or the like. Hollow rods and tool holders of the type shown here are known and will therefore not be described in detail here. Through the tool holder 5, torque is generally transmitted into the tool 1, so that the tool turns to machine the hole in the workpiece. The tool 1 is now pivoted about its center axis 7 .

[0022] The cutting head 3 has a body 9 with a peripheral surface 11 into which at least one cutting element 13 and at least one guide 15 are inserted. Usually, a plurality of such guide elements (also referred to as guide strips) are inserted into the body 9, which intercept the forces transmitted to the tool 1 by the cutting element 13 during the machining of the workpiece and guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com