Processing method for green rocking of sandalwood oolong

A processing method and technology of oolong tea, applied in the processing field of sandalwood oolong tea, can solve problems such as lack of production process of sandalwood oolong tea

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

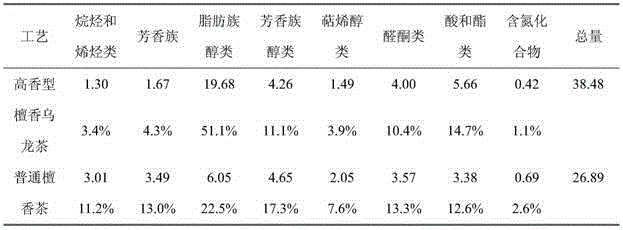

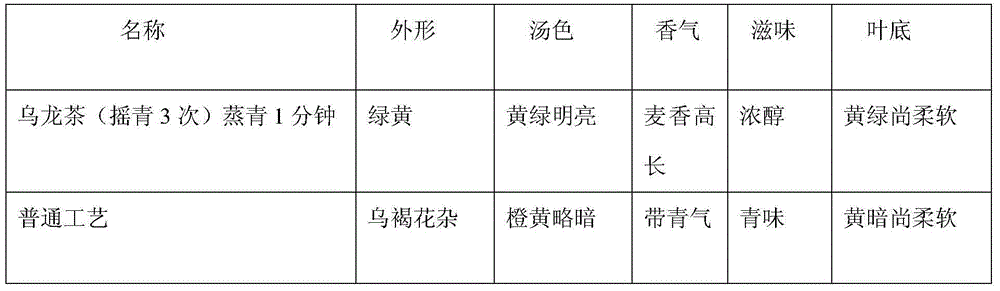

Embodiment 1

[0019] A kind of high fragrance type sandalwood oolong tea shaking green processing method, its steps are as follows:

[0020] (1) Fresh sandalwood leaves are picked, and the tenderness is controlled at one bud and one leaf;

[0021] (2) Spread fresh leaf raw materials according to the leaf thickness of 3 or 4 or 5 cm, and spread them for 4 or 5 hours to obtain spread leaves;

[0022] (3) Shake the green leaves 2 or 3 or 4 times in a simple shaker. The speed of the shaker is 20 rpm, and each shake takes 1 or 2 or 3 minutes. Carry out cold blue and green 58 or 59 or 60 or 61 or 62 minutes processing between the second shake;

[0023] (4) Spread green leaves for 1 or 2 hours, steam green leaves in an electric steamer for 1 or 2 minutes, and control the steaming temperature at 110 or 114 or 117 or 120°C to obtain green leaves;

[0024] (5) Fry the green leaves in a reciprocating multi-function machine (type 6CDY-60) (fire drying), the machine speed is 1000 rpm, the amount of le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com