Novel flat green tea processing technology

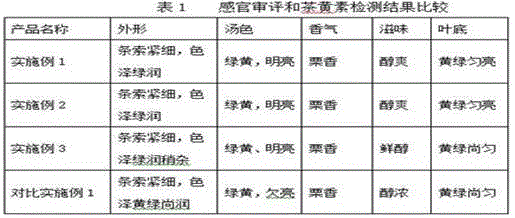

A flat-shaped green tea and processing technology technology, applied in the field of tea, can solve the problems of increased aroma and taste, water-stuffy taste, unfavorable industrialized production of tea, and long time for cooling and rejuvenation, so as to reduce the aroma and taste, and facilitate industrialization. Production, soup color green-yellow bright effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of processing technology of flat green tea, comprises the following steps:

[0019] (1) Pick fresh single buds of tea trees, and spread green leaves for 8 hours at a temperature of 30°C and a humidity of 85%, until the color of the tea green leaves turns dark green, and the water content is 73%, and the green leaves are spread;

[0020] (2) Finishing, the process is divided into two stages, the first stage is hot air curing at 300°C, and the second stage is microwave curing at 130°C;

[0021] (3) Moisturize, place the green tea leaves at a temperature of 30-40°C and a relative humidity of 60%-80% for cooling and regaining moisture for 30-45 minutes;

[0022] (4) The flat tea is used as the shaping process, the temperature of the flat tea frying machine is set at 180°C, and the frying time is 20 minutes. Then adopt the traditional secondary drying process (that is, use the 6CTH6 tea drying and aroma enhancing machine, set the initial drying temperature at 110°C, ...

Embodiment 2

[0025] A kind of processing technology of flat green tea, comprises the following steps:

[0026] (1) Pick a new shoot of a tea tree with a bud and a leaf, and spread it green for 7 hours at a temperature of 32°C and a humidity of 78%. When the color of the tea green turns dark green and the water content is 68%, the green leaves are spread;

[0027] (2) Finishing, the process is divided into two sections, the first section is hot air finishing at 290°C, and the second section is microwave finishing at 120°C;

[0028] (3) Moisturize, place the green tea leaves at a temperature of 30-40°C and a relative humidity of 60%-80% for cooling and regaining moisture for 30-45 minutes;

[0029] (4) The flat tea is used as the shaping process, the temperature of the flat tea frying machine is set at 180°C, and the frying time is 20 minutes. Then adopt the traditional secondary drying process (set the initial drying temperature at 110°C, take 20 minutes, dry to a moisture content of 10-15...

Embodiment 3

[0032] A kind of processing technology of flat green tea, comprises the following steps:

[0033] (1) Fresh leaves: Pick the new shoots of tea trees with one bud and two leaves, and spread them green for 6 hours at a temperature of 35°C and a humidity of 65%. When the green color turns dark green and the water content is 65%, green leaves are spread;

[0034] (2) Finishing, the process is divided into two sections, the first section is hot air finishing at 280°C, and the second section is microwave finishing at 100°C;

[0035] (3) Moisturize, place the green tea leaves at a temperature of 30-40°C and a relative humidity of 60%-80% for cooling and regaining moisture for 30-45 minutes;

[0036] (4) The flat tea is used as the shaping process, the temperature of the flat tea frying machine is set at 180°C, and the frying time is 20 minutes. Then use the traditional secondary drying process (the initial drying temperature is set at 110°C, it takes 20 minutes, dry to a moisture co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com