High-quality yellow tea preparation method

A high-quality, tea-leaf technology, applied in the field of high-quality yellow tea preparation, to achieve the effects of improving quality, reducing time costs, and having a green and buttery appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

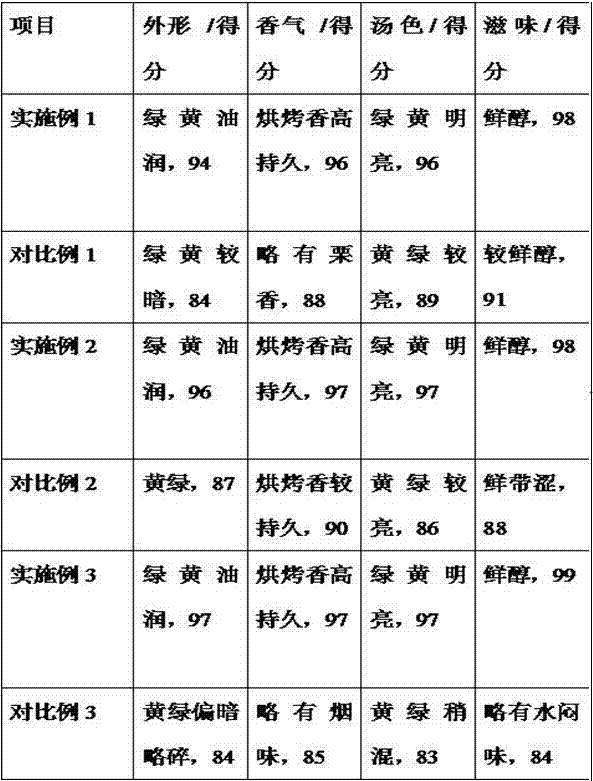

Examples

Embodiment 1

[0017] A preparation method for high-quality yellow tea, comprising the following steps:

[0018] (1) Evenly spray the L-tryptophan solution with a mass fraction of 0.3% on the picked fresh tea leaves, and then ultrasonically treat the tea leaves for 15 minutes;

[0019] (2) Spread the ultrasonically treated tea leaves, and then perform high-temperature rapid de-enzyming. The de-enzyming temperature is 190°C, and the de-enzyming time is 3 minutes;

[0020] (3) Preliminarily dry the green tea leaves, knead them lightly, then put them in an environment of 60°C, carry out a dull yellowing treatment for 270 minutes, and finally dry the tea leaves to obtain a finished product.

[0021] Specifically, the above-mentioned picked fresh tea leaves contain bud stalks, and the length of the bud stalks is 1-2 cm.

[0022] Specifically, during the above-mentioned ultrasonic treatment, the frequency of the ultrasonic wave is 30 kHz.

[0023] Specifically, the temperature during the prelimi...

Embodiment 2

[0026] A preparation method for high-quality yellow tea, comprising the following steps:

[0027] (1) Evenly spray L-tryptophan solution with a mass fraction of 0.4% on the picked fresh tea leaves, and then ultrasonically treat the tea leaves for 20 minutes;

[0028] (2) Spread the ultrasonically treated tea leaves, and then perform high-temperature rapid de-enzyming. The de-enzyming temperature is 210°C, and the de-enzyming time is 3 minutes;

[0029] (3) Preliminarily dry the green tea leaves, knead them lightly, then put them in an environment of 63° C., carry out a dull yellowing treatment for 280 minutes, and finally dry the tea leaves to obtain a finished product.

[0030] Specifically, the above-mentioned picked fresh tea leaves contain bud stalks, and the length of the bud stalks is 1-2 cm.

[0031] Specifically, during the above-mentioned ultrasonic treatment, the frequency of the ultrasonic wave is 33 kHz.

[0032] Specifically, the temperature during the prelimina...

Embodiment 3

[0035] A preparation method for high-quality yellow tea, comprising the following steps:

[0036] (1) Evenly spray the L-tryptophan solution with a mass fraction of 0.6% on the picked fresh tea leaves, and then ultrasonically treat the tea leaves for 25 minutes;

[0037] (2) Spread the ultrasonically treated tea leaves, and then perform high-temperature rapid de-enzyming. The de-enzyming temperature is 220°C, and the de-enzyming time is 3 minutes;

[0038] (3) Preliminarily dry the green tea leaves, knead them lightly, put them in an environment of 65° C., carry out a dull yellowing treatment for 300 minutes, and finally dry the tea leaves to obtain a finished product.

[0039] Specifically, the above-mentioned picked fresh tea leaves contain bud stalks, and the length of the bud stalks is 2 cm.

[0040] Specifically, during the above-mentioned ultrasonic treatment, the frequency of the ultrasonic wave is 35 kHz.

[0041] Specifically, the temperature during the preliminary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com