Xanthoceras sorbifolia Bunge health-care oil processing method

A processing method and technology of health-care oil, applied in the fields of frozen dessert, food science, application, etc., can solve the problems of waste of ingredients and not necessarily good taste, and achieve the effect of preserving nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for processing Xantho sorbifolium health-care oil, is characterized in that, comprises the steps:

[0022] Drying, drying the sorbifolia at 25-35 degrees Celsius for two hours;

[0023] Pulverizing, pulverizing the radix sorbifolium, and rolling after pulverizing;

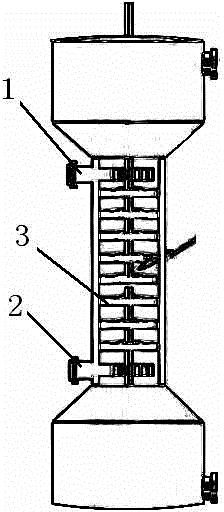

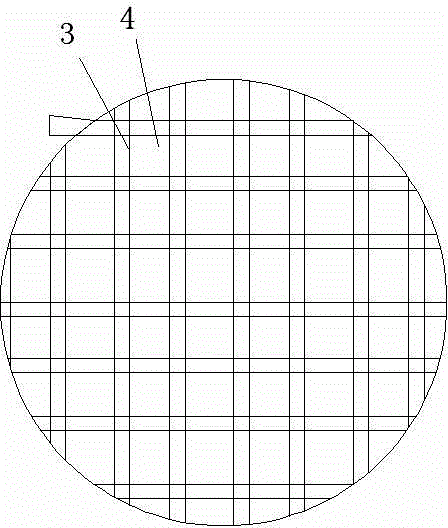

[0024] Place a multi-layer sorting net in the extraction tower, the mesh of the sorting net gradually becomes smaller from top to bottom, and the bottom layer is a 200-mesh sieve, and the pulverized material is poured from top to bottom;

[0025] Using absolute ethanol to carry out circulation extraction for 2 hours;

[0026] The absolute ethanol in the extracted liquid was distilled off.

[0027] The essential distinguishing technical features of the technical solution here and the substantial technical effects it plays and its realization process are as follows:

[0028] Due to the placement of multi-layer sorting nets, the meshes of the sorting nets gradually become smaller from top to bottom,...

Embodiment 2

[0031] Based on the first embodiment; the sorting net is composed of hollow pipes, and the hollow pipes are connected to the outer pipe and then connected to the hot water pipe; the temperature of the sorting net can be adjusted by feeding hot water.

[0032] The substantive technical effect and its realization process played by the essential difference technical features of the technical solution here are as follows:

[0033] Adjust the temperature of each area according to the demand, so that different temperature areas are treated separately for extraction, and at the same time, it helps to speed up the extraction speed.

Embodiment 3

[0035] Based on Embodiment 1; the sorting net is composed of hollow pipes, the walls of the hollow pipes contain fine holes, and the hollow pipes are connected with anhydrous ethanol solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com