Compound humic packing biological filter system, combined-technology wastewater treatment system and wastewater treatment method

A humic filler and biofilter technology, applied in aerobic and anaerobic process treatment, filtration treatment, adsorption water/sewage treatment, etc., can solve the problem of slow rise of TP concentration in effluent, low TN removal rate, and suspension in influent Sensitivity to the concentration of substances and other issues, to reduce the risk of bio-blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] The following is an illustration based on a specific case. The discharge of domestic sewage in a natural village is 10m 3 / d, the water quality of sewage influent is shown in Table 1:

[0075] Table 1 A natural village domestic sewage water quality data

[0076]

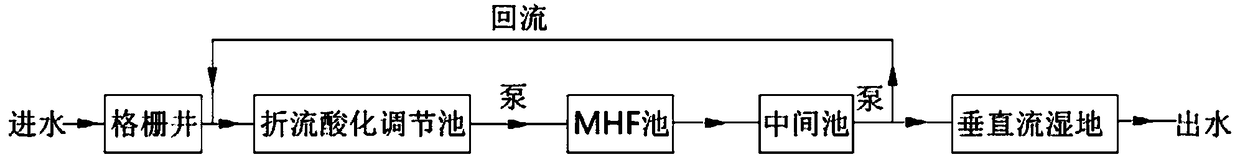

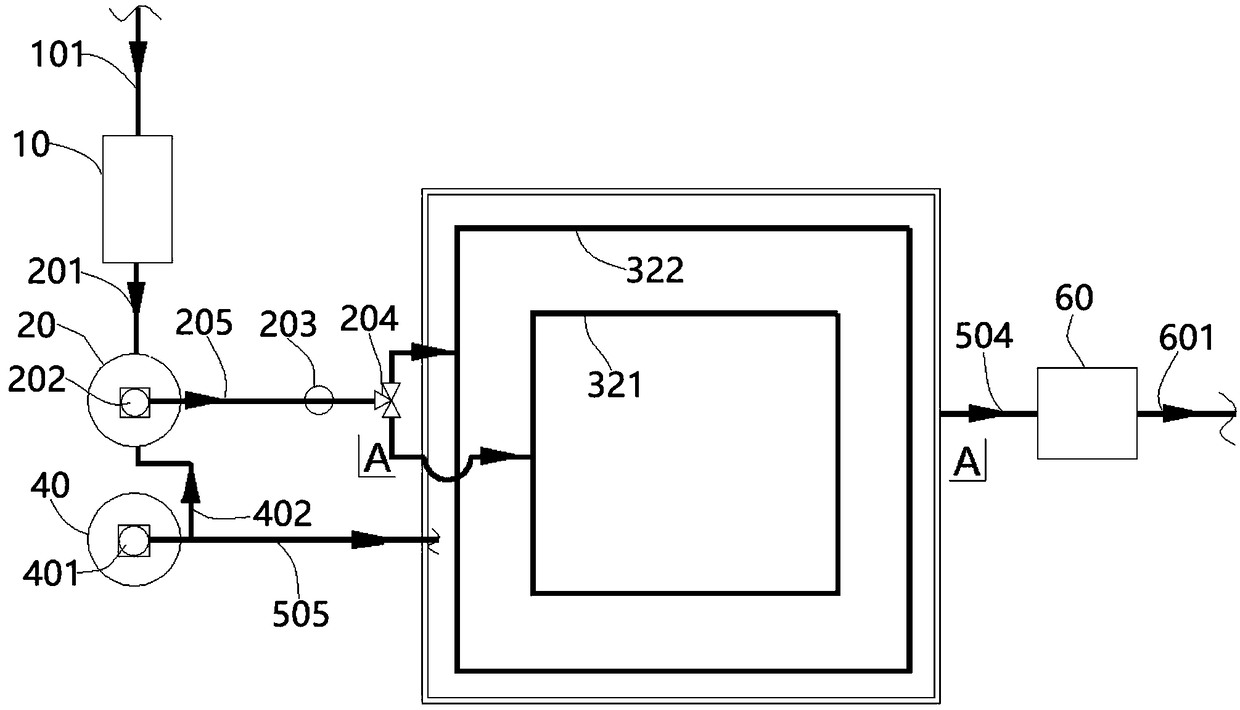

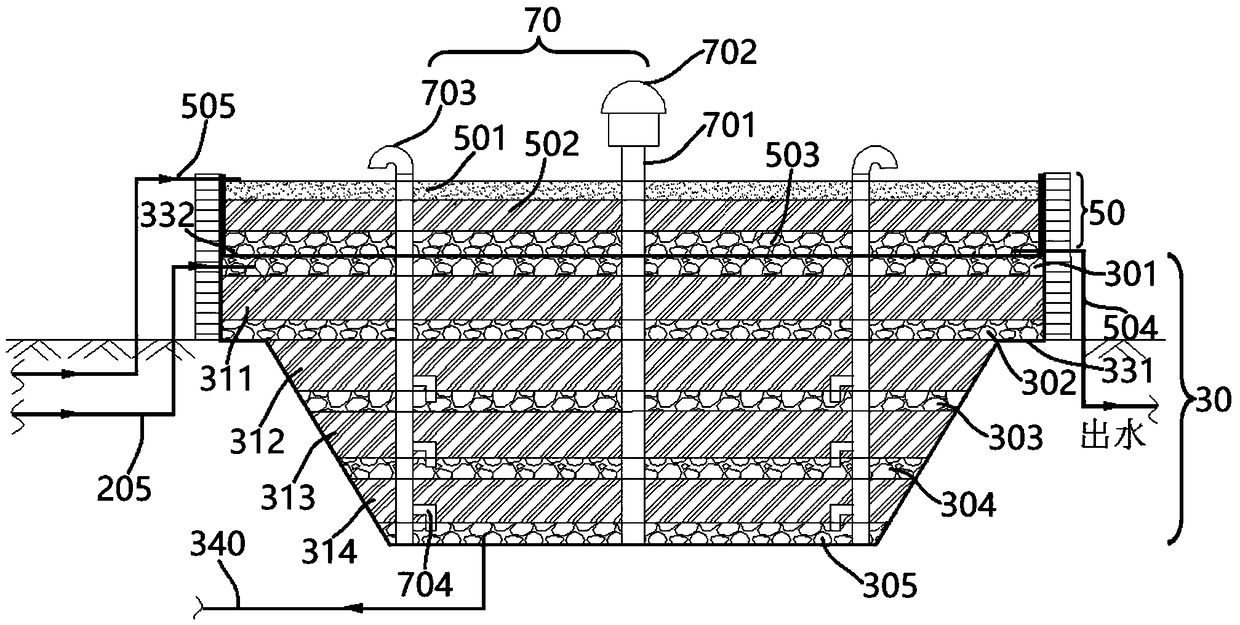

[0077] combine figure 1 , a method for treating degradable organic wastewater such as domestic sewage in this embodiment, the sewage passes through the grid well 10 to remove larger-scale suspended matter and enters the baffle acidification adjustment tank 20 for pretreatment, and the macromolecular organic matter is hydrolyzed into small molecular organic matter , the water from the sewage lifting pump 202 goes through the self-cleaning filter 203 to remove fine suspended matter and then enters the top water distribution unit of the composite humic filler biofilter 30 . The grid well 10 is 1m long and 0.7m wide, and the depth is determined by adding 1m to the buried depth of the end of the sewage collect...

Embodiment 2

[0082] The daily discharge of domestic sewage in natural village B is 50m 3 / d, the water quality of sewage influent is shown in Table 2:

[0083] Table 2 Water quality data of domestic sewage in Natural Village B

[0084]

[0085] A kind of composite humic filler biofilter system of this embodiment, its structure is basically the same as that of embodiment 1, the difference is: the composite humic filler biofilter 30 is a flexible pool constructed by semi-underground composite geomembrane enclosure body, the length of the above-ground part is 12m, and the width is 12m. According to the surface load of the composite humic filler biofilter 30, the water inlet surface load is controlled to 0.75m 3 / (m 2 d), and calculate the bottom area according to the surface load of the water inlet, that is, the effective area is 75m 2 , the actual bottom length is 9m, and the width is 9m. The baffle acidification adjustment pool 20 adopts the baffle form of a circular rotating flow ch...

Embodiment 3

[0088] The daily flow of domestic sewage in natural village C is 100m 3 / d, the quality of sewage influent is shown in Table 3:

[0089] Table 3 Water quality of domestic sewage in natural village C

[0090]

[0091] A combined process wastewater treatment system in this embodiment is basically the same in structure as in Embodiment 1, except that the composite humic filler biofilter 30 adopts a semi-subterranean composite geomembrane enclosure to construct a flexible pool body. Partial length is 14m, width is 14m, according to the composite humic filler biofilter 30 influent surface load control is 0.75m 3 / (m 2 d), and calculate the bottom area according to the surface load of the water inlet, that is, the effective area is 150m 2 , the actual base length is 12.5m, and the width is 12.5m. Due to the large amount of treated water, the baffled acidification adjustment tank 20 adopts a corridor-type baffled square pool body, and the required effective volume is 12.5m 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com