Intelligent explosive ordnance disposal robot

A detonation robot and intelligent technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of high risk in the detonation process of explosives, the overall performance cannot meet the requirements, and threaten the life safety of detonation personnel, so as to improve the detonation efficiency and safety, the detonation process is faster and safer, and the effect of reasonable space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

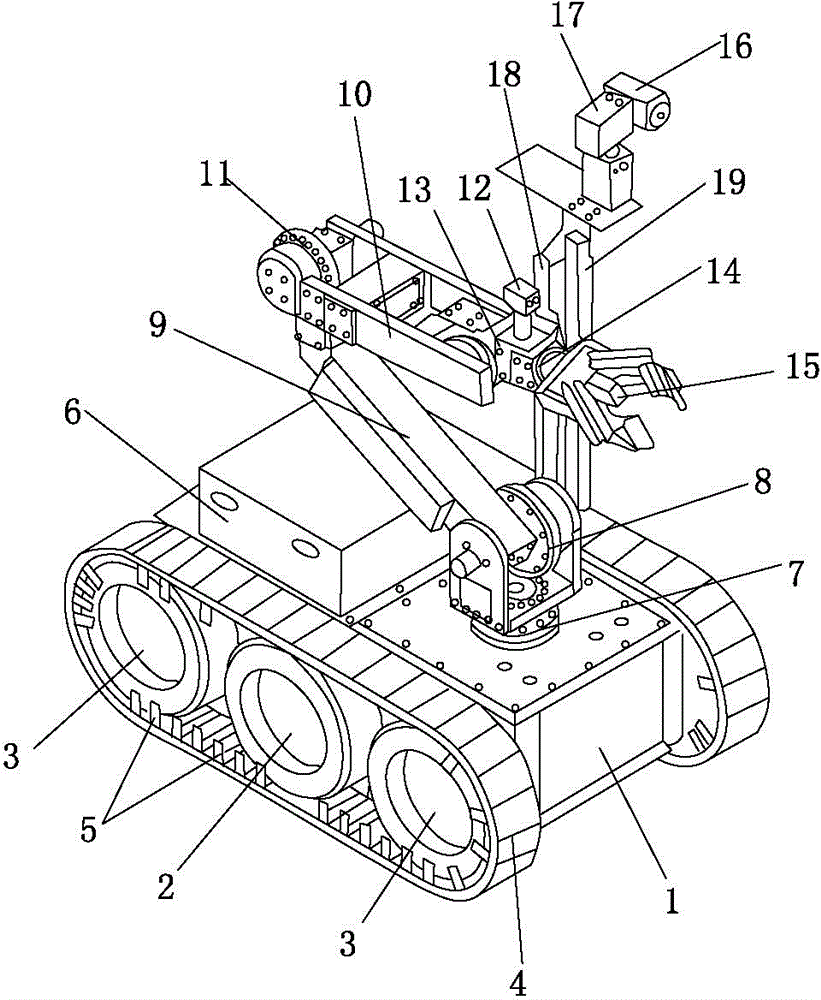

[0022] Such as figure 1 As shown, the intelligent explosion-proof robot of this embodiment includes a car body 1 and a drive system symmetrically arranged on both sides of the car body 1. The car body 1 is also provided with an operating system and a control system 6. The control system 6 It is respectively connected with the driving system and the operating system. The driving system includes the supporting wheel 2 connected with the car body 1, the driving wheel 3 arranged at both ends of the supporting wheel 2 and the crawler belt 4. The crawler belt 4 is sleeved on the supporting wheel. The periphery of heavy wheel 2 and driving wheel 3;

[0023] The operating system includes a waist joint system that is movably connected to the vehicle body 1, a shoulder joint system that is movably connected to the lumbar joint system, a robotic arm system that is movably connected to the shoulder joint system, and a terminal end set at the end of the robotic arm system. Executor 15, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com