Movable soil feeder capable of being used under complicated work conditions

A mobile technology with complex working conditions, applied in the field of engineering, it can solve the problems of inability to climb the length of the slope, small conveying capacity, and inability to work normally, and achieve the effect of excellent equipment itself, long conveying distance and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

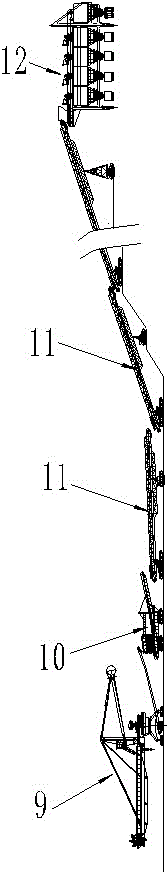

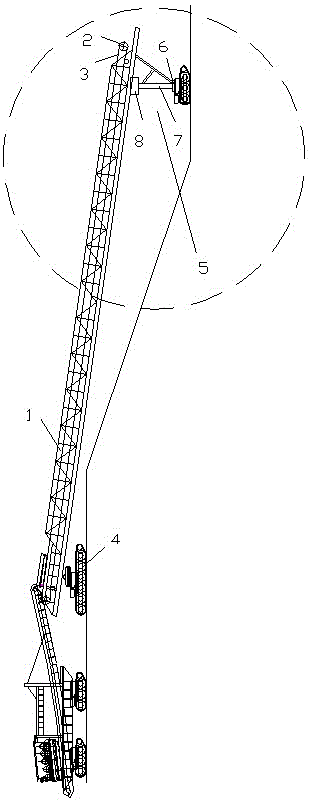

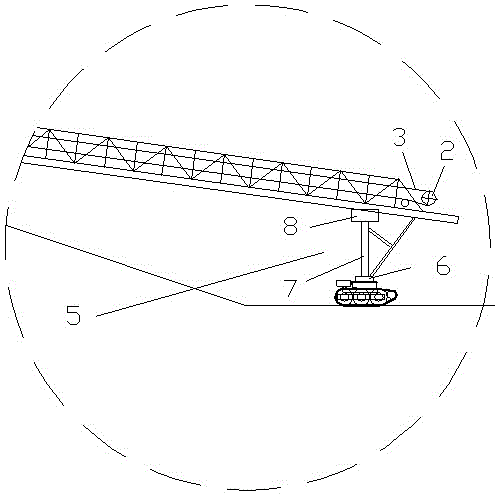

[0023] Such as Figure 1 to Figure 3 As shown, a mobile soil loading machine that can be used under complex working conditions includes a high-efficiency excavator 9, a mobile crusher 10, a mobile belt conveyor 11 and a mobile unloader 12 connected in sequence. The mobile belt conveyor 11 includes a conveyor frame 1, rollers 2 installed at both ends of the conveyor frame 1 and a running device below the conveyor frame 1, the rollers 2 at both ends are connected by a conveyor belt 3, and the running device is a crawler belt Wheel 4, a crawler wheel chassis is arranged above the track wheel 4, and a slewing bearing is provided on the track wheel chassis to connect with the upper conveyor frame 1, which can realize 360° ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com