A construction method for hanging cylinders of Maerz lime kiln

A construction method and a hanging cylinder technology are applied in the construction field of lime kilns, which can solve the problems of cracking, inconvenience and strength reduction of magnesia bricks, and achieve the effects of improving quality, simple operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The construction method of Maierzi lime kiln suspension cylinder of the present invention comprises the following steps:

[0036] a. Prefabricated baking device, comprising the following steps:

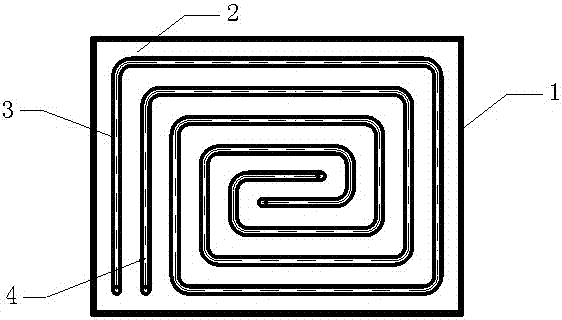

[0037] see now figure 1 , figure 1 It is a structural schematic diagram of a baking device according to an embodiment of the present invention.

[0038] (1) Prefabricate several baking devices according to the design drawings of the hanging cylinder of the Maerz lime kiln. As shown in the figure, the baking device uses 30*3mm flat steel 1 to make the frame of the baking device, and the bottom of the frame is provided with a support The structure is used to carry insulation bricks, and the frame is made to form a rectangular flat steel frame with an area of 500*372mm;

[0039] (2) Put 6 pieces of diatomite heat insulation bricks of 230*114*64mm in each flat steel frame. After the heat insulation bricks are put in, arrange grooves on the heat insulation bricks in a back shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com