Hot-dip galvanized steel sheet and production method thereof

A technology of hot-dip galvanized steel sheet and production method, applied in hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as difficult to control Mn content, difficult process implementation, poor strength, etc., and achieve difficult implementation The effect of small size, excellent surface quality and comprehensive quality performance, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

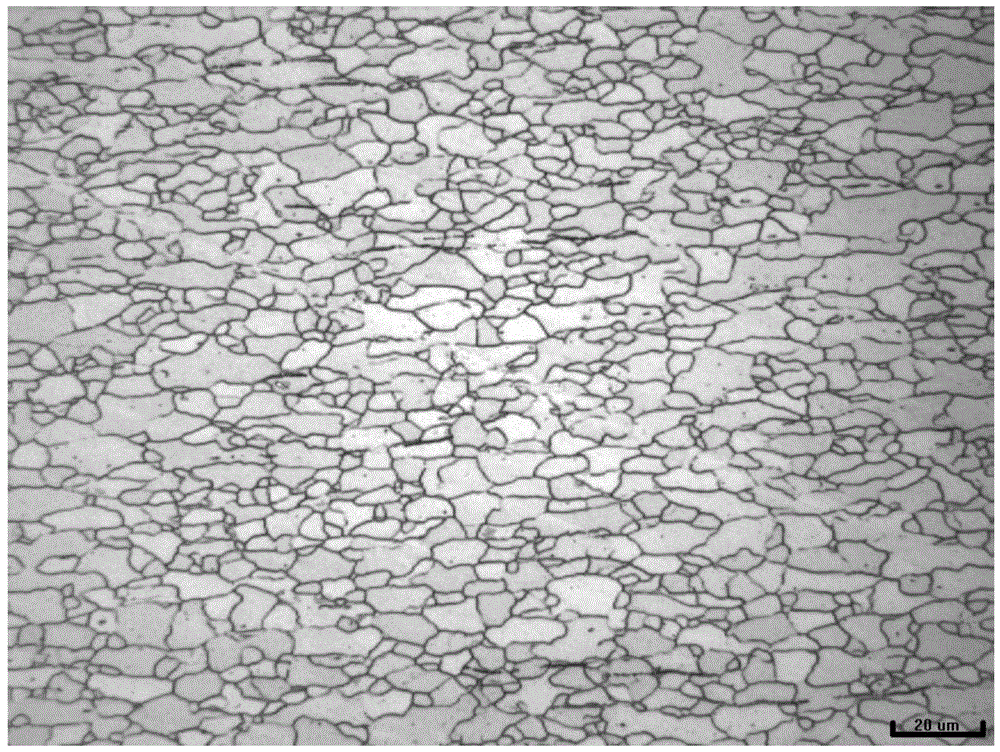

Image

Examples

Embodiment 1

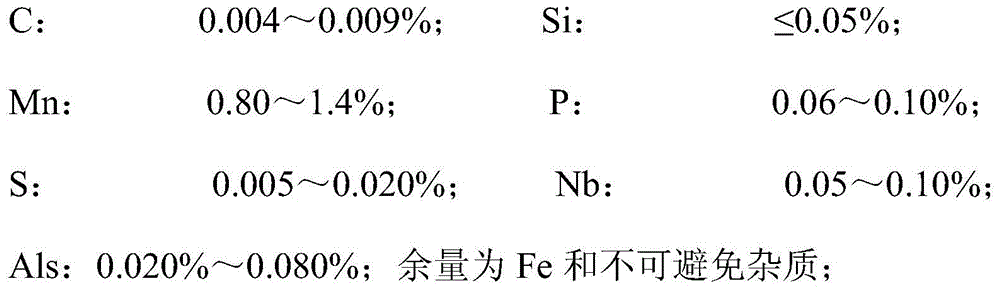

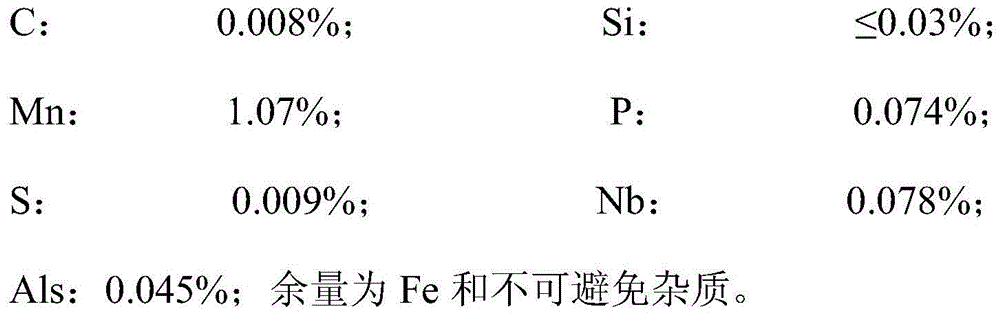

[0056] Control the composition of molten steel in the following range: C: 0.008%, Si: 0.03%, Mn: 1.07%, P: 0.074%, S: 0.009%, Nb: 0.078%, Als: 0.045, the balance is Fe and unavoidable impurities Composition, using a continuous casting machine to continuously cast it into a continuous casting slab with a thickness of 195mm.

[0057] The continuous casting slab is heated to 1176°C in a walking heating furnace, followed by rough rolling with a two-roll reversible roughing mill at a final rolling temperature of 1060°C to obtain an intermediate slab with a thickness of 36.4mm, which is then transferred to a hot coil box by coreless transfer Coiling; then use the six-stand continuous rolling mill to carry out finish rolling on the intermediate slab, the start rolling temperature is 980°C, and the finish rolling temperature is 926°C; after finish rolling, the temperature is lowered at a cooling rate of 82°C / s to 801°C, and then cooled to 615°C at a cooling rate of 13°C / s, and then co...

Embodiment 2

[0065] Control the composition of molten steel in the following range: C: 0.006%, Si: 0.02%, Mn: 0.8%, P: 0.061%, S: 0.006%, Nb: 0.063%, Als: 0.032, the balance is Fe and unavoidable impurities Composition, using a continuous casting machine to continuously cast it into a continuous casting slab with a thickness of 200mm.

[0066] The continuous casting slab is heated to 1166°C in a walking heating furnace, followed by rough rolling with a two-roll reversible roughing mill at a final rolling temperature of 1092°C to obtain an intermediate slab with a thickness of 35.4mm, which is then transferred to a hot coil box using a coreless transfer Coiling; then use the six-stand continuous rolling mill to carry out finish rolling on the intermediate slab, the starting rolling temperature is 978°C, and the finishing rolling temperature is 911°C; after finishing rolling, the temperature is lowered at a cooling rate of 78°C / s to 788°C, and then cooled to 603°C at a cooling rate of 15°C / s...

Embodiment 3

[0073] Control the composition of molten steel in the following range: C: 0.007%, Si: 0.04%, Mn: 1.32%, P: 0.09%, S: 0.013%, Nb: 0.08%, Als: 0.07, the balance is Fe and unavoidable impurities Composition, using a continuous casting machine to continuously cast it into a continuous casting slab with a thickness of 190mm.

[0074] The continuous casting slab is heated to 1156°C in a walking heating furnace, followed by rough rolling with a two-roll reversible roughing mill at a final rolling temperature of 1076°C to obtain an intermediate slab with a thickness of 34.8mm, which is then transferred to a hot coil box using a coreless transfer Coiling; then use the six-stand continuous rolling mill to carry out finish rolling on the intermediate slab, the starting rolling temperature is 988°C, and the finishing rolling temperature is 895°C; after finishing rolling, the temperature is lowered at a cooling rate of 88°C / s to 815°C, and then cooled to 595°C at a cooling rate of 18°C / s, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com