Engine control unit

A technology for engine controllers and actuators, which is applied in the direction of engine control, engine components, combustion engines, etc., and can solve problems such as cost concentration, unexpected shutdown of internal combustion engines, and failure of magnetic actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention relates to an engine controller of an internal combustion engine, especially a medium-speed four-stroke internal combustion engine (which uses diesel oil, heavy oil or gas as fuel).

[0033] Such internal combustion engines are preferably marine engines.

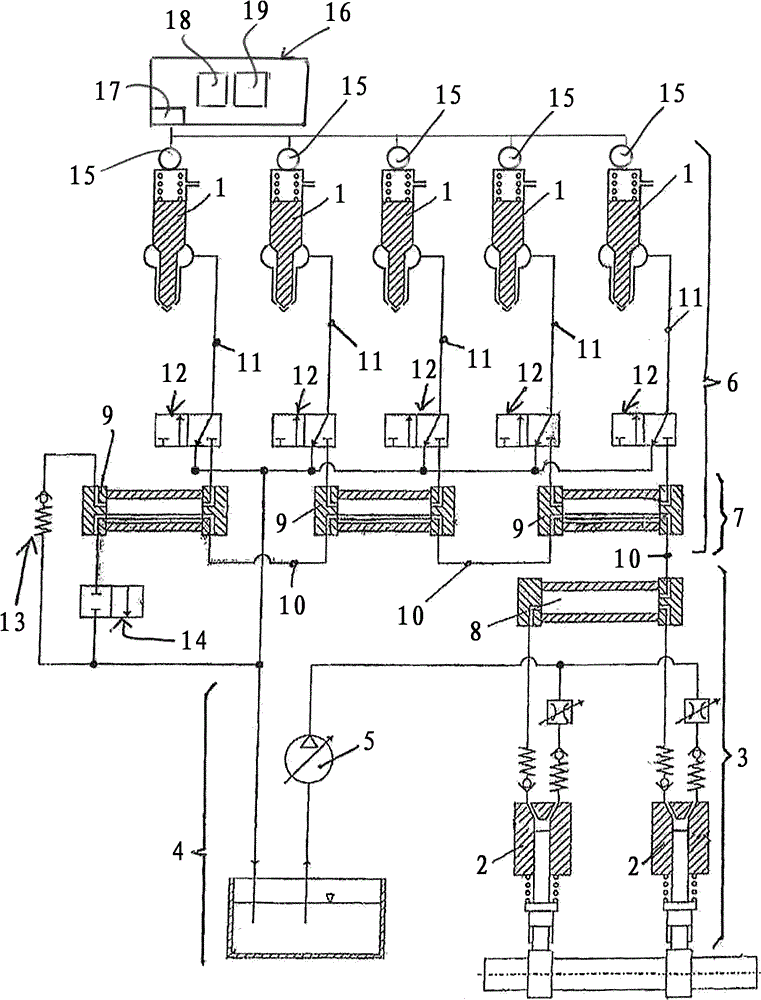

[0034] Such internal combustion engines typically have a common rail fuel supply, the basic structure of which is familiar to those skilled in the art and referred to figure 1 to explain the description. Such a fuel supply has a magnetic actuator 15 which can be actuated by a motor controller 16 . exist figure 1 , such a magnetic actuator 15 is shown in the region of the injector 1 .

[0035] It is proposed within the meaning of the present invention that the engine controller 16 includes means to automatically determine the value of at least one magnetic characteristic parameter of the magnetic actuator 15 built in the fuel supply system when the internal combustion engine is stopped and the fuel sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com