Lighting Components and Surgical Lights

A technology for lighting components and lighting units, applied in the field of lighting, can solve problems such as low light collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

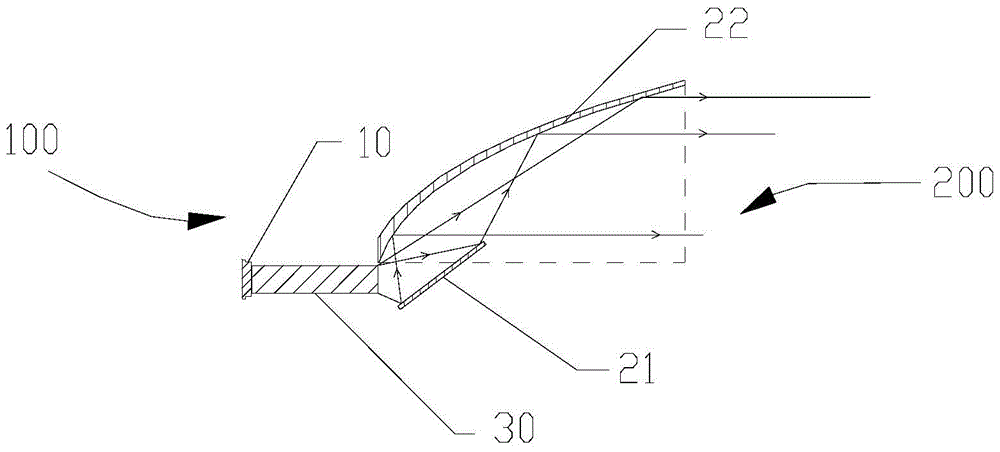

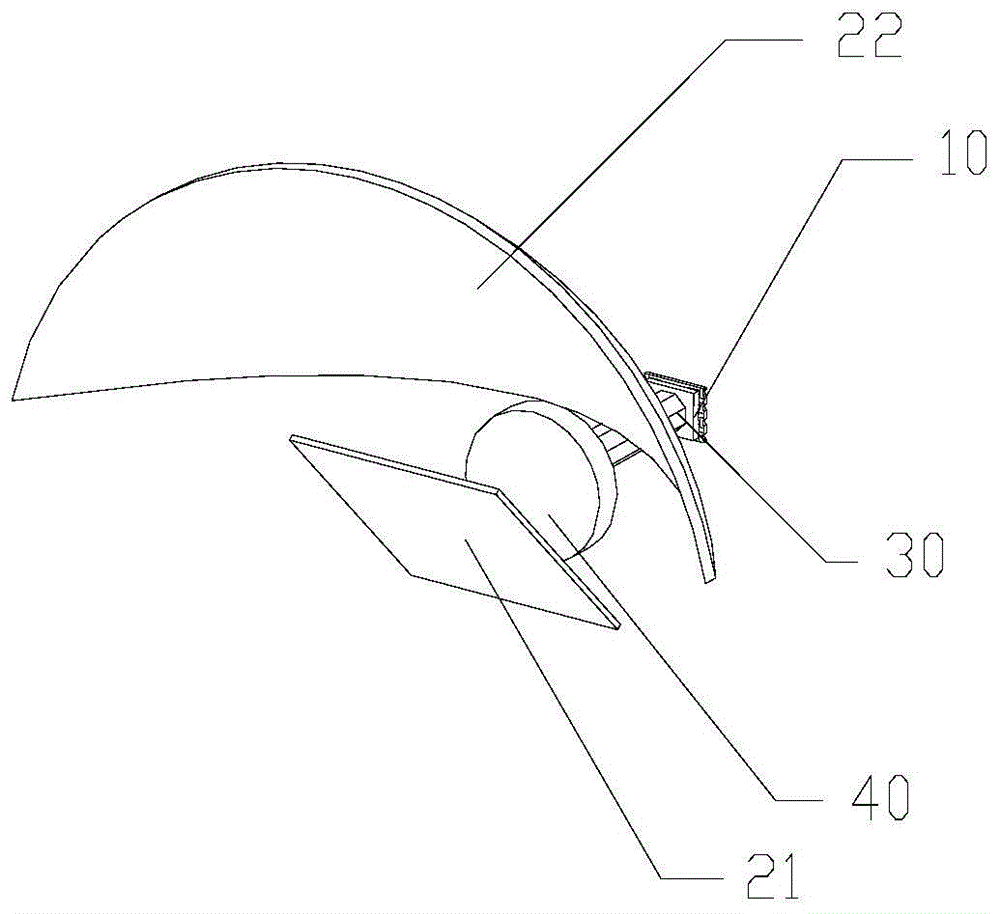

[0046] like figure 1 As shown, a lighting assembly includes a lighting unit 100 and a reflective cup 200. The lighting unit 100 includes a light source 10. The reflective cup 200 has an incident end and an outgoing end. The incident end of the reflective cup 200 is an end that receives light from the light source. The exit end of the light source is the end that emits the light from the light source. The lighting unit 100 is located on one side of the incident end of the reflective cup 200 . The reflective cup 200 includes a first reflective element 21 and a second reflective element 22 . The first reflective element 21 has a reflective surface, the reflective surface of the first reflective element 21 is a plane, the surface of which can be coated with a reflective film, specifically, the first reflective element 21 is a plane reflective mirror. The second reflective element 22 also has a reflective surface. The reflective surface of the second reflective element 22 is a s...

Embodiment 2

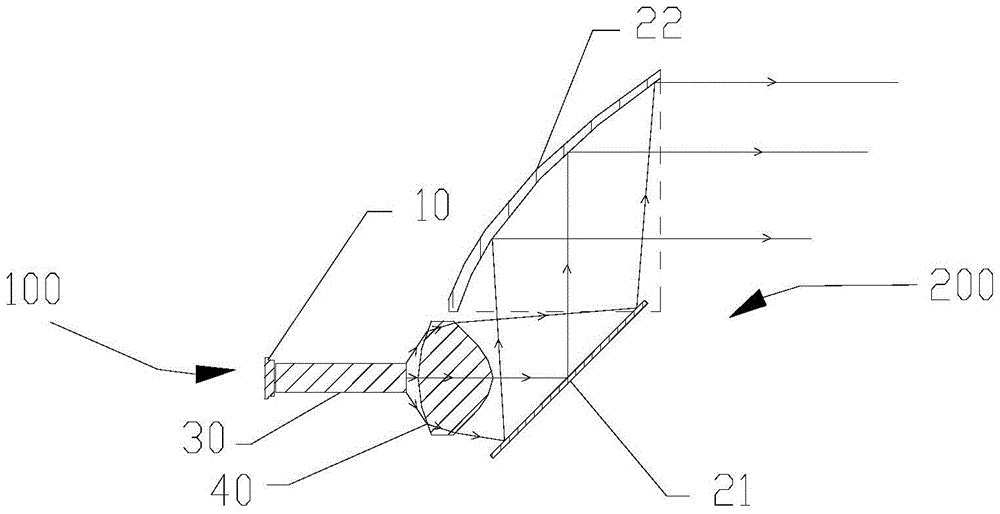

[0058] like Figure 2A and Figure 2B As shown, on the basis of Embodiment 1, the lighting unit 100 may further include a first lens 40 . When the first light mixing integrating rod 30 is omitted, the first lens 40 is located between the light source 10 and the incident end of the reflector cup 20, and when the first light mixing integrating rod 30 is used, the first lens 40 is located at the first light mixing integrating rod 30 and the incident end of the reflective cup 20. The first lens 40 uses a positive lens, preferably a positive lens made of a cold-processed glass material. The positive lens has a converging effect, and the divergent light emitted directly from the light source 10 or the first mixing rod 30 passes through the first lens 40 Convergence, the light angle is converged to Left and right, the angle has been relatively reduced, and further, the lighting unit 100 has a virtual light source symmetrically with respect to the first reflective element 21. 21 ...

Embodiment 3

[0062] like image 3 As shown, on the basis of Embodiment 1, the lighting assembly further includes a first reflector 60 , if the first integrating rod 30 is omitted, the first reflector 60 is located between the light source 10 and the reflector 20 . If the first light mixing rod integrator 30 is used, the first reflection part 60 is located between the first light mixing rod integrator 30 and the incident end of the reflective cup 200 .

[0063] The end of the first reflection part 60 close to the light source is the incident end, and the end close to the reflective cup is the exit end. The first reflector 60 can be cylindrical or conical, and a through hole is provided in the first reflector 60. The through hole is in the shape of a conical truncated hole. The diameter of the aperture gradually increases from the incident end to the exit end, and the through hole of the first reflection part 60 is coated with a reflection mold to form a reflection surface, and the inclinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com