Touch-type automatic control device system of medium roasting oven

An automatic control device and a technology for frying stoves, which are applied to household stoves/stoves, household heating, lighting and heating equipment, etc., can solve the problems of hard friction thermal machinery, excessive fatigue, etc., to save fuel, save manufacturing costs, avoid The effect of reactive combustion waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

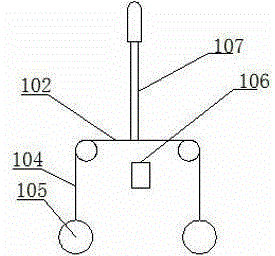

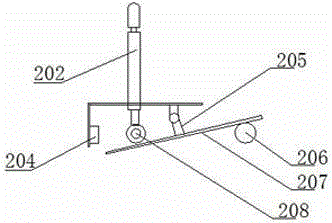

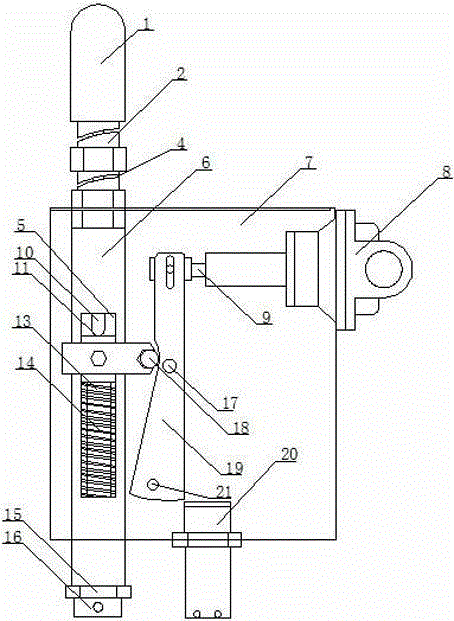

[0021] Such as image 3 As shown, a kind of touch automatic control device system for medium frying stove of the present invention includes a console 7, a conduit 6 fixed on the left side of the console 7, a proximity switch 20 installed at the lower end of the console 7, and a control panel installed on the control panel 7. Air valve 8 on the upper right of platform 7, flat nut 15 and spring screw 16 are installed at the lower end of the conduit 6, connecting rod 2 is set on the upper end of the conduit 6, and a pressure cap 1 is fixed on the upper end of the connecting rod 2. The lower end of the connecting rod 2 is fixed with a tappet 10, and the conduit 6 is provided with a spring 14 and a clip spring tube 11, wherein one end of the spring 14 is fixed on the spring screw 16 at the lower end of the conduit 6, and the other end is fixed on the clip spring tube 11 lower end, A slide block 13 is fixed on the clip spring tube 11, a steel ball 18 is installed at the right end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com