Laser interference control method for grating mechanical ruling engine

A grating marking machine and mechanical marking technology, applied in the direction of digital control, electrical program control, etc., can solve the problems of the influence of marking positioning accuracy and the inability to meet the requirements of fast control of the position of the marking line of the grating, so as to improve the performance index of the grating, Improve online monitoring speed and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

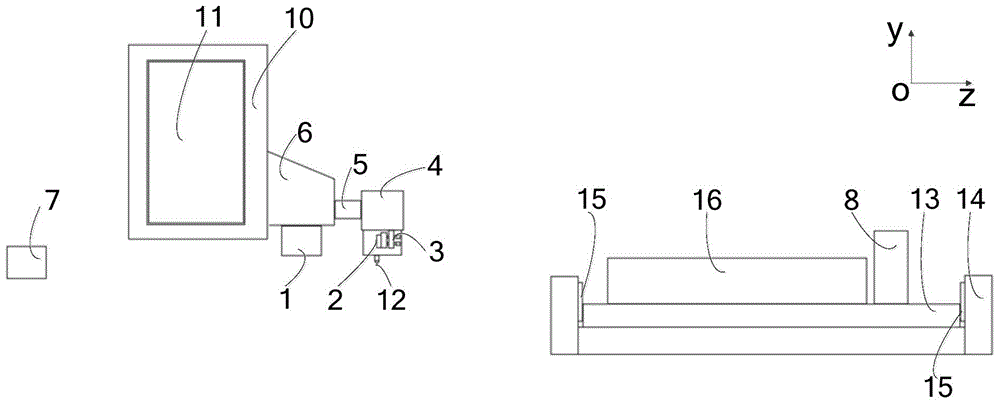

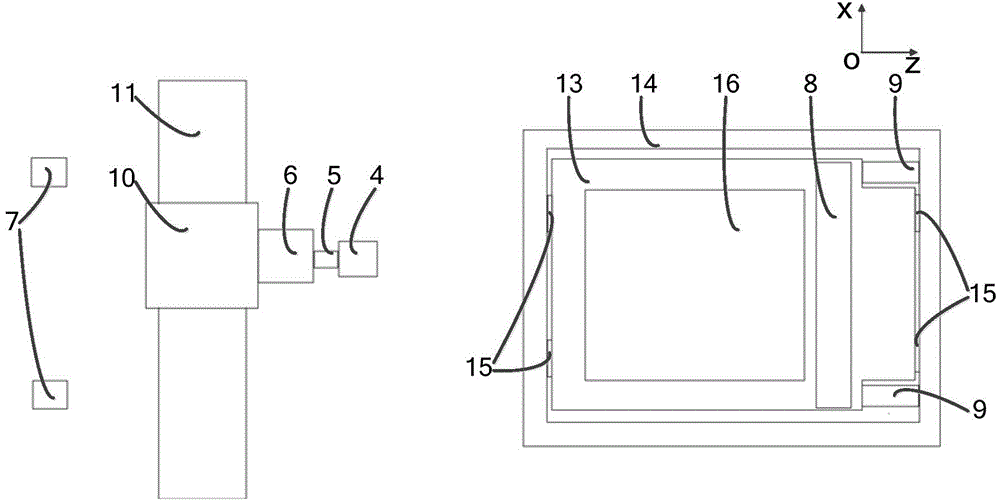

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] See attached figure 1 And attached figure 2 The device used to realize the laser interference control method of a grating mechanical marking machine of the present invention includes a grating knife interferometer 1, a reference mirror 2, a two-dimensional adjustment frame 3, a marking tool holder 4, a grating knife press Electric actuator 5, sliding sleeve adapter plate 6, workbench interferometer 7, strip measuring mirror 8, workbench piezoelectric actuator 9, air-floating sliding sleeve 10, air-floating guide rail 11, grating cutter 12, workbench Inner platform 13, workbench outer platform 14, elastic steel sheet 15 and grating base 16;

[0024] The grating knife interferometer 1 is composed of a 10721 dual-axis differential interferometer from the American Keysight Company and a plane mirror at an angle of 45 degrees. The workbench interfe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com