Photoelectric composite communication cable

A photoelectric composite and optical fiber technology, applied in communication cables, cables, circuits, etc., can solve the problems of complicated wiring, money and labor, and save money and increase costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

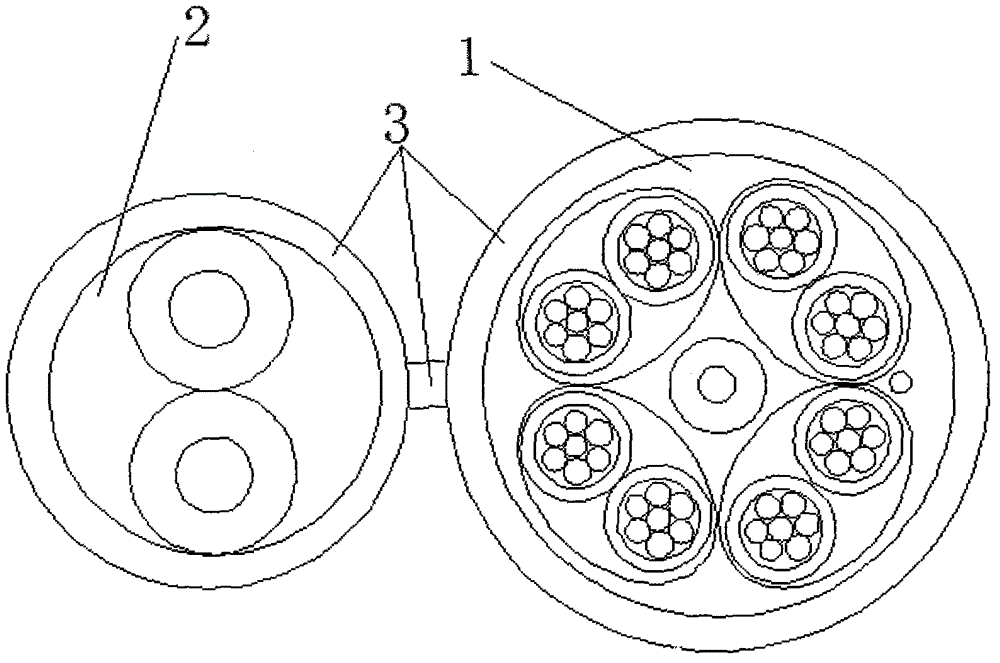

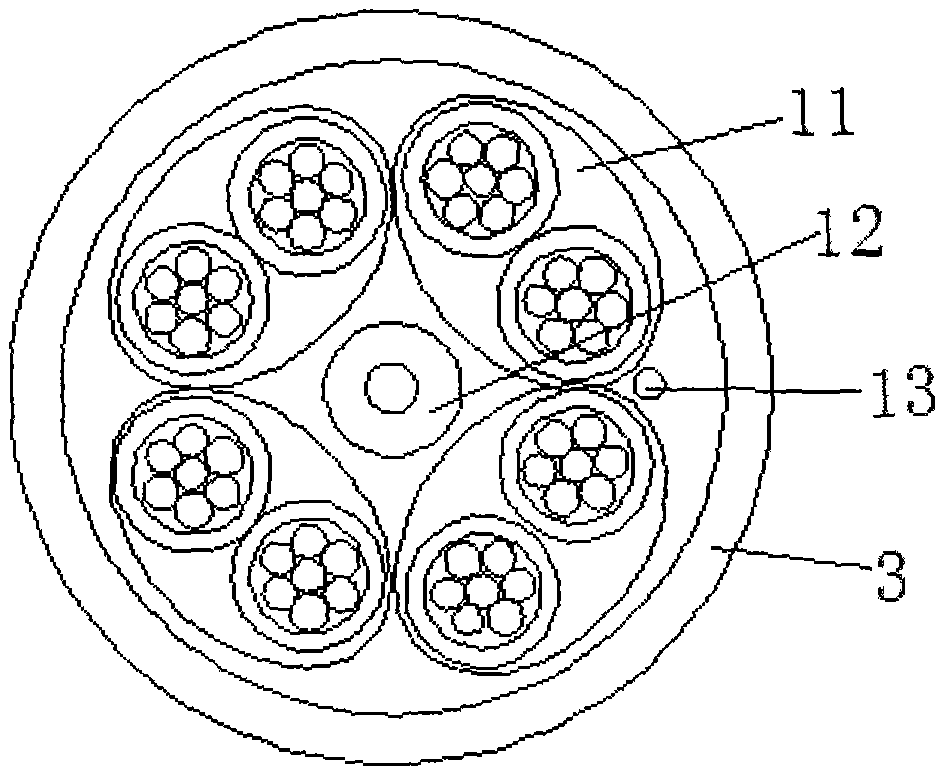

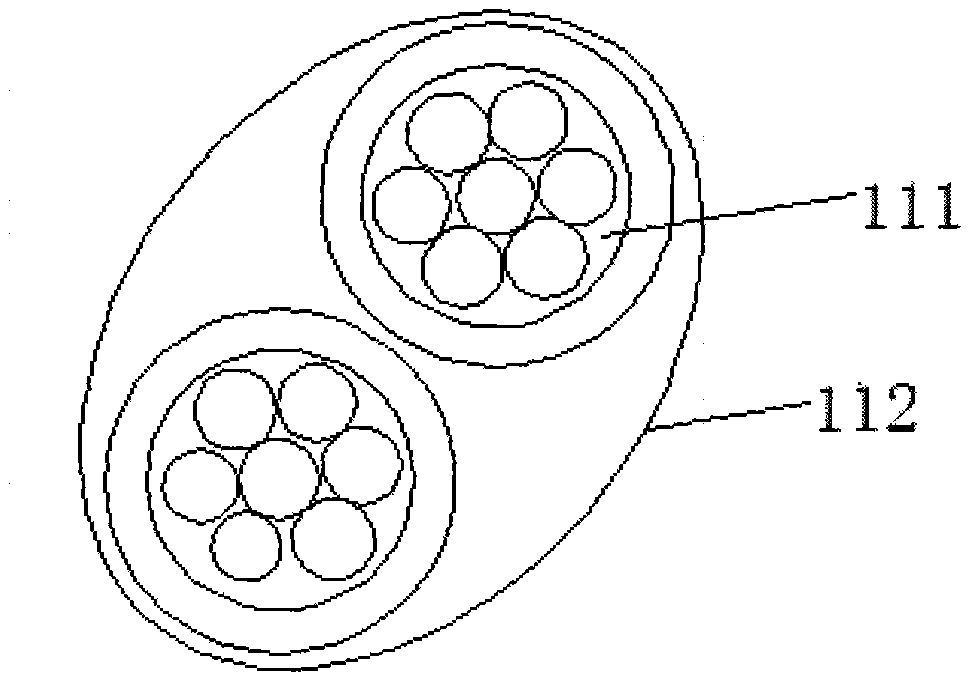

[0035] Such as figure 1 , figure 2 , image 3 , Figure 4 Figure 5 As shown, a photoelectric composite communication cable is composed of a signal line (1), a power line (2) and an insulating sheath (3), and is characterized in that: the signal line (1) and the power line (2) form " 8" font structure, the signal line (1) and the power line (2) are connected by an insulating jacket (33); the signal line (1) is composed of a metal network cable unit (11), an optical fiber (12), and a drain wire (13) and insulating jacket (3), characterized in that: the metal mesh cable units (11) are closely arranged in a ring with the optical fiber (12) as the center, and the drain wires (13) are located in two groups of metal mesh cables The gap of the unit (11) is close to the inner surface of the insulating jacket (3); the power line (2) is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com