Charger automatically adaptive to lead-acid battery pack voltage

A technology of automatic adaptation and battery pack, applied in the electronic field, can solve the problems of rising cost of electrical equipment and incompatibility of chargers, etc., and achieve the effect of cost saving and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

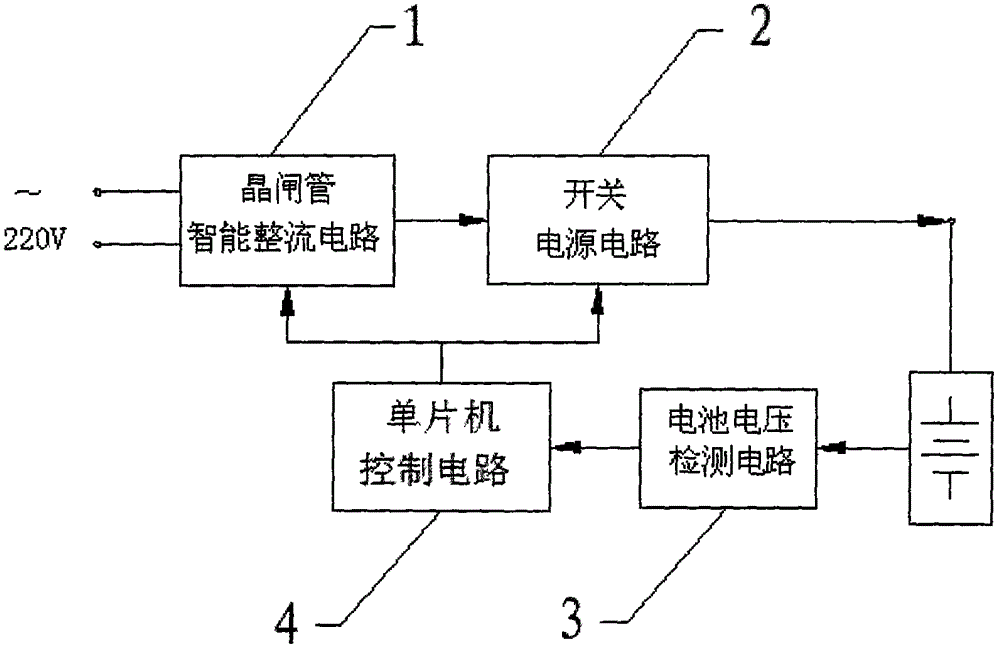

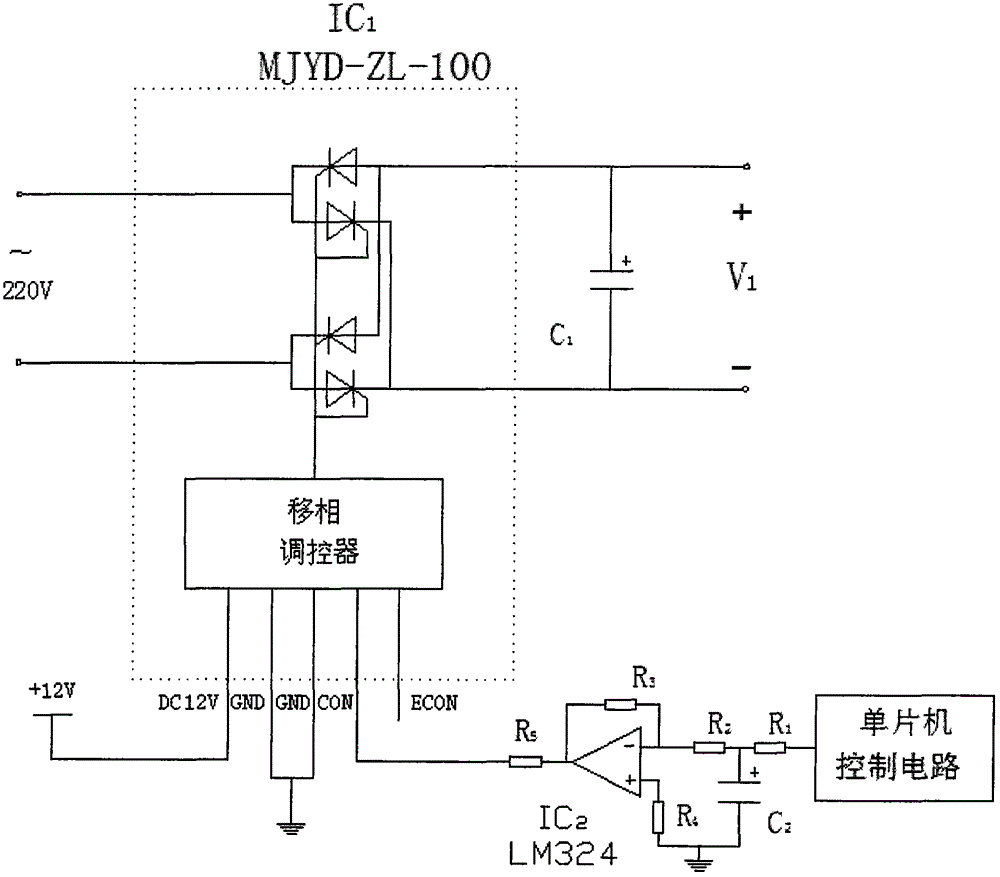

[0027] like figure 1 As shown, a charger that automatically adapts to the voltage of a lead-acid battery pack includes a thyristor intelligent rectifier circuit 1, a switching power supply circuit 2, a voltage sampling circuit, a battery voltage detection circuit 3 and a single-chip microcomputer control circuit 4.

[0028] The thyristor intelligent rectifier circuit 1 is a rectifier circuit capable of changing the output voltage under the action of a control signal.

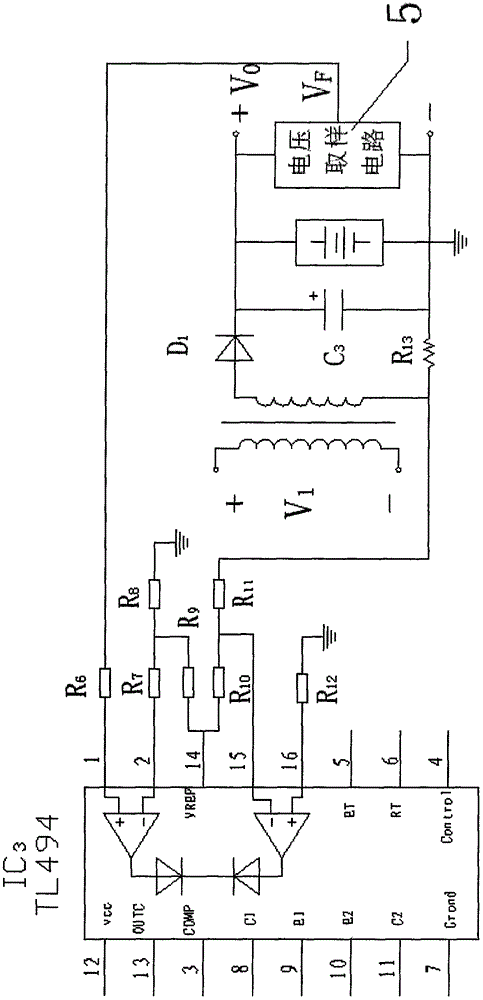

[0029] The switching power supply circuit 2 is a regulated power supply circuit that can change the output voltage by changing the data of the voltage sampling circuit;

[0030] The battery voltage detection circuit 3 measures the no-load voltage of the battery, and converts the voltage signal into an 8-bit binary digital signal to the single-chip microcomputer circuit 4 through an A / D conversion circuit as a basis for judging the number of battery cells.

[0031] The voltage sampling circuit is a unit of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com