Method for winding box tube by using box tube winding equipment of paper speaker

A technology using paper and speakers, applied in the transducer shell/cabinet/stand and other directions, can solve the problems of high cost, sound quality defects, poor rigidity, etc., to achieve strong resistance to sonic shock, consistent winding density, comprehensive indicators improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

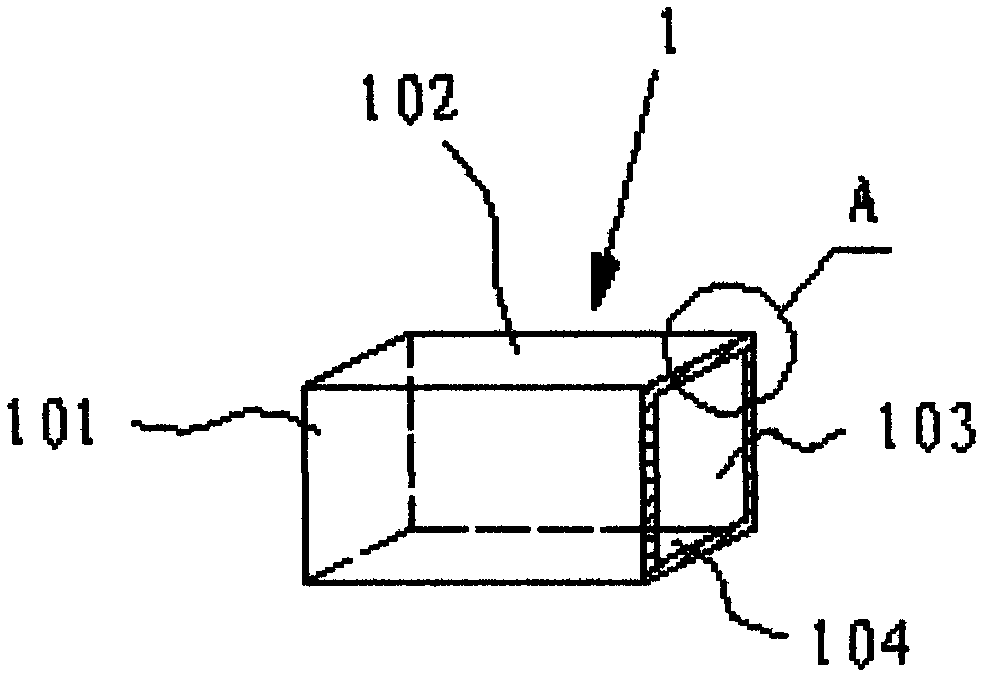

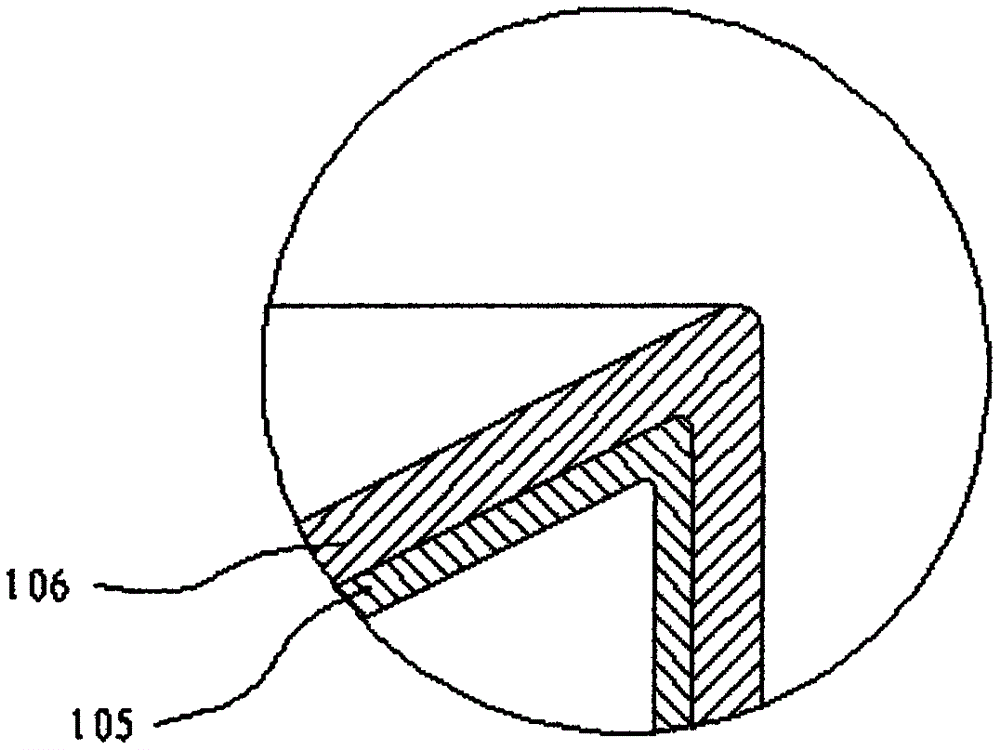

[0025] like figure 1 and figure 2 As shown, the paper sound box of the present invention includes a box body, a sounding element installed on the box body, cables, and terminals, the front wall plate 101, the upper wall plate 102, and the rear wall of the box body The board 103 and the lower wall board 104 are a square box tube 1 with an integral structure wound by wood pulp paper and ordinary board paper. Adhesives are coated between the winding layers, and the wood pulp paper is wound to form the square box. The inner wall 105 of the tube 1, the common board paper is wound to form the outer wall 106 of the square box tube 1, the thickness of the inner wall 106 is 0.6 millimeters, and the thickness of the outer wall 105 is 9 millimeters, glued on the outer side of the outer wall 106 Attached to the decorative layer.

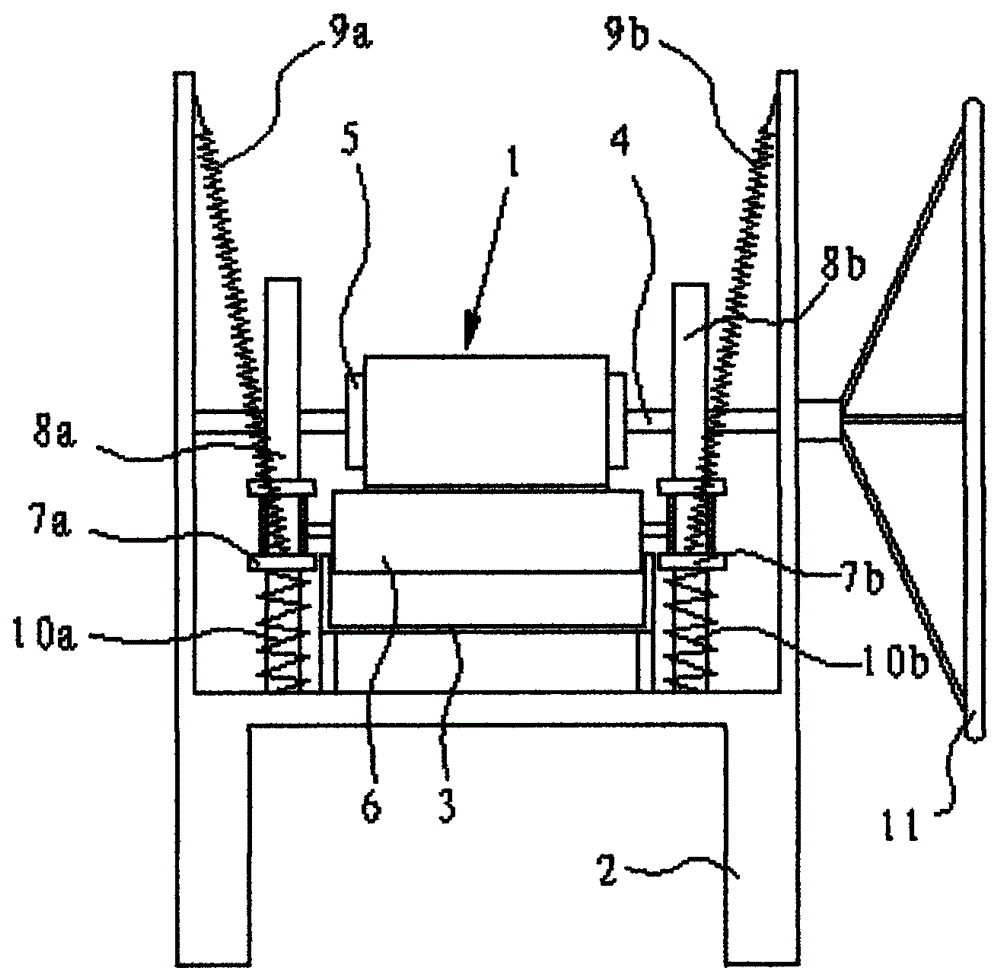

[0026] like image 3 As shown, the box winding equipment for winding the square box 1 of the paper sound box according to the present invention includes a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com