Disengagement system for a clutch of a motor vehicle

A separation system and clutch technology, applied in non-mechanical drive clutches, fluid drive clutches, clutches, etc., to achieve the effect of reducing tolerance chains, reducing costs, and requiring less precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

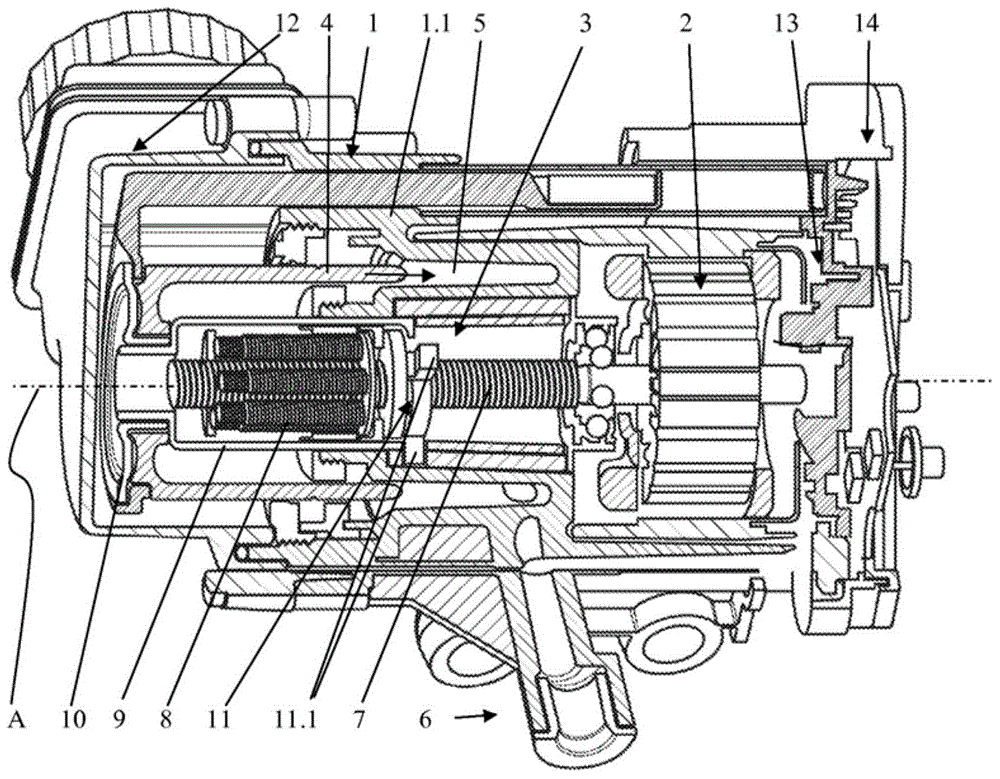

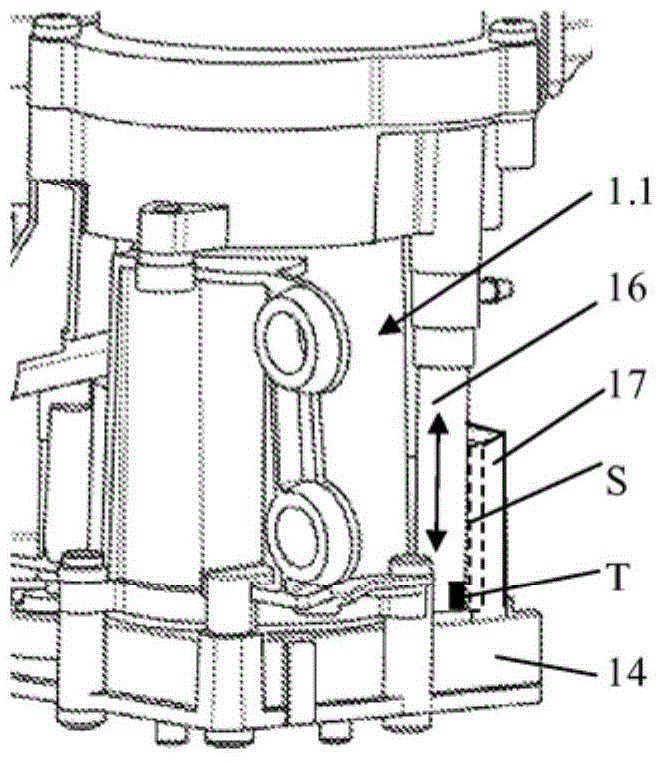

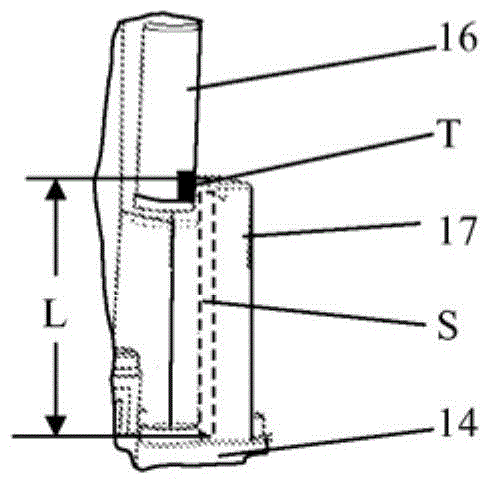

[0039] exist figure 1 A longitudinal sectional view of the separation system according to the invention is shown in to illustrate the principle structure. The disconnect system is designed here as a disconnect in the form of a hydraulic clutch actuator (HCA), wherein the master cylinder 1 can be actuated via the transmission 3 by means of a drive in the form of an electric motor 2 .

[0040] In the housing 1 . 1 of the master cylinder 1 , a piston 4 (annular piston) is arranged axially displaceable via a transmission 3 when the electric motor 2 is actuated. When the piston 4 is actuated in the axial direction, here to the right in the direction of the arrow, pressure builds up in the pressure chamber 5 formed by the housing 1 and the piston 4 . The pressure chamber 5 is connected via a pressure medium connection 6 and a not shown hydraulic line to a slave cylinder, also not shown, which actuates a clutch (not shown) via a release mechanism.

[0041] The transmission 3 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com