A magnetically responsive multi-gradient drug-loaded microsphere prepared by double in situ hybridization

A multi-gradient, magnetic responsive technology, applied in the fields of organic active ingredients, pharmaceutical science, drug combination, etc., to achieve the effect of simple preparation procedure, good biomagnetic orientation, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

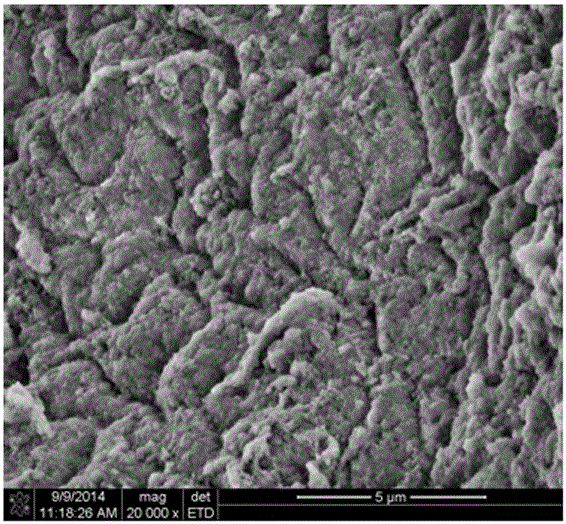

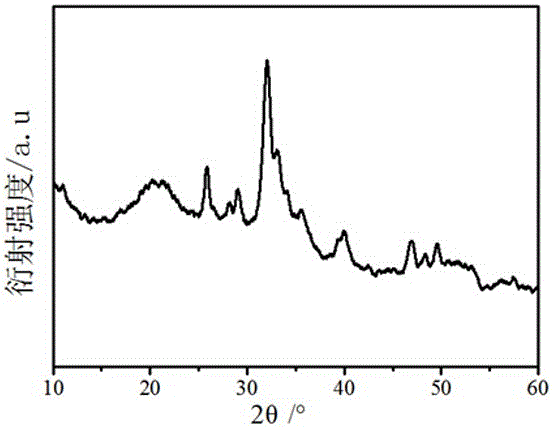

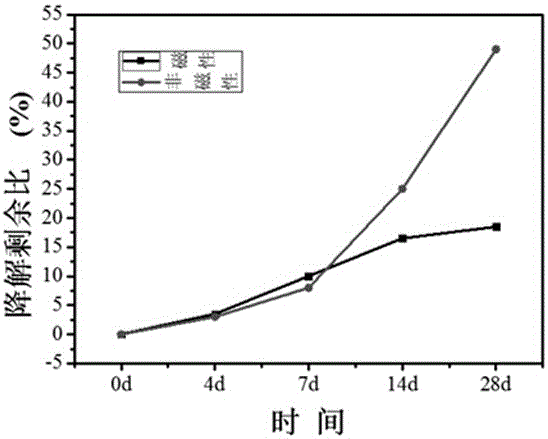

Image

Examples

Embodiment 1

[0036] (1) Dissolving icariin in absolute ethanol, dissolving chitosan in an acetic acid solution with a volume fraction of 1%, and adding the alcohol solution of icariin to the acetic acid solution of chitosan under magnetic stirring , stirring to make each component mix evenly, and the content of chitosan and icariin calculated by mass percentage is 2% and 0.05% respectively;

[0037] (2) According to n(Fe 3+ ): n(Fe 2+)=2:1 ratio, a certain amount of soluble iron salt and soluble ferrous salt were added to the above mixture, and the two were continuously stirred for 30min, and the theoretically formed Fe 3 o 4 The mass ratio is 2%;

[0038] (3) Prepare a 1.5mol / L soluble calcium salt solution, add it to the mixed solution obtained in (2), and keep stirring to make it fully mixed evenly to obtain a mixed solution of microsphere precursor;

[0039] (4) Prepare 0.5mol / L NaOH ethanol / water solution, wherein the volume ratio of ethanol to water is 1~2:1, and prepare 1.8mol / L...

Embodiment 2

[0044] (1) Dissolving icariin in absolute ethanol, dissolving chitosan in an acetic acid solution with a volume fraction of 1%, and adding the alcohol solution of icariin to the acetic acid solution of chitosan under magnetic stirring , stirring to make each component mix evenly, and the contents of chitosan and icariin calculated by mass percentage are 1.5%, 0.08% respectively;

[0045] (2) According to n(Fe 3+ ): n(Fe 2+ )=2:1 ratio, a certain amount of soluble iron salt and soluble ferrous salt were added to the above mixture, and the two were continuously stirred for 45min, and the theoretically formed Fe 3 o 4 The mass ratio is 3%;

[0046] (3) Prepare 2.4mol / L soluble calcium salt solution, add it to the mixed solution obtained in (2), and keep stirring to make it fully mixed evenly to obtain the microsphere precursor mixed solution;

[0047] (4) Prepare 1.0mol / L NaOH ethanol / water solution, wherein the volume ratio of ethanol to water is 1~2:1, and prepare 1.2mol / L ...

Embodiment 3

[0052] (1) Dissolving icariin in absolute ethanol, dissolving chitosan in an acetic acid solution with a volume fraction of 2%, and under magnetic stirring, add the alcohol solution of icariin to the acetic acid solution of chitosan , stirring to make each component mix evenly, and the content of chitosan and icariin calculated by mass percentage is 2.5%, 0.03% respectively;

[0053] (2) According to n(Fe 3+ ): n(Fe 2+ )=2:1 ratio, a certain amount of soluble ferrous salt and soluble ferrous salt were added to the above mixture, and the two were continuously stirred for 1h, and the theoretically formed Fe 3 o 4 The mass ratio is 4%;

[0054] (3) Prepare a 3mol / L soluble calcium salt solution, add it to the mixed solution obtained in (2), and keep stirring to make it fully mixed evenly to obtain the microsphere precursor mixed solution;

[0055] (4) Prepare 1.5mol / L NaOH ethanol / water solution, wherein the volume ratio of ethanol to water is 1-2:1, and prepare 0.6mol / L solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com